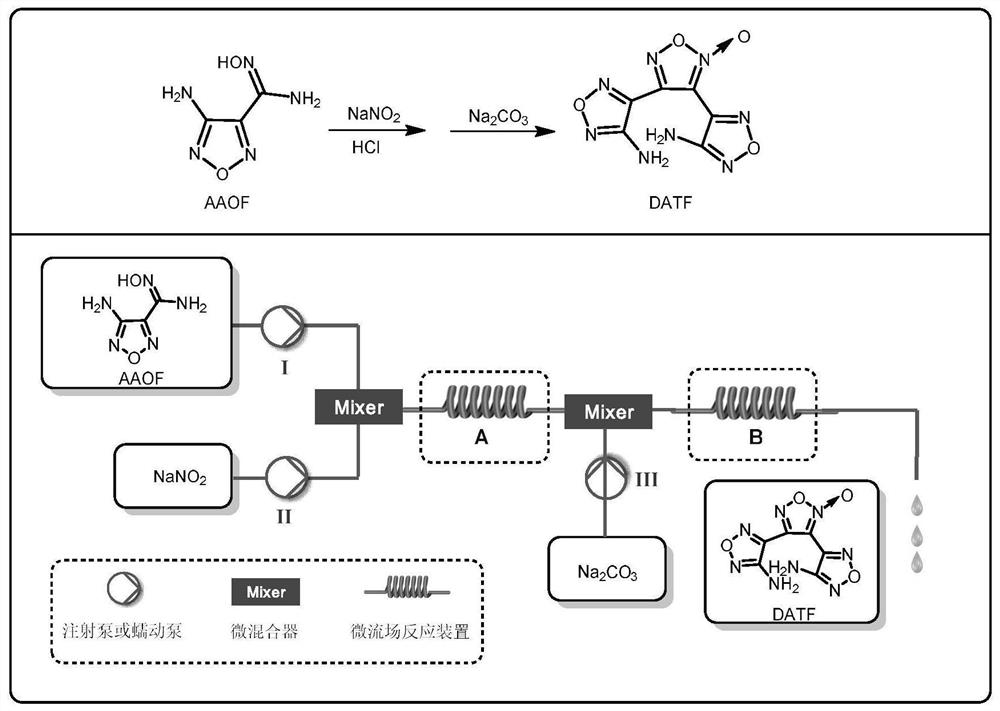

Method for continuously preparing 3, 4-bis(4'-aminofurazan-3'-yl) furoxan by adopting micro-channel reactor

A microchannel reactor, aminofurazan technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, organic chemistry, etc., can solve the problems of uncontrollable large-scale production safety, difficult engineering applications, " There are many problems such as the discharge of three wastes, etc., to achieve the effect of improving the conversion rate of raw materials, good mixing effect of materials, and improving reaction selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

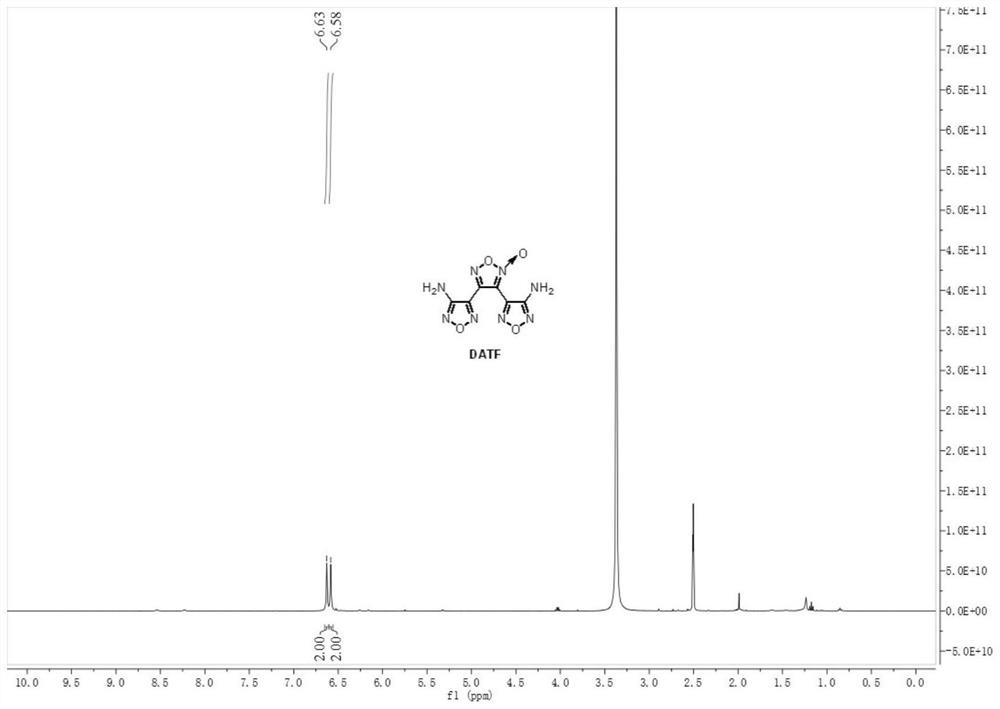

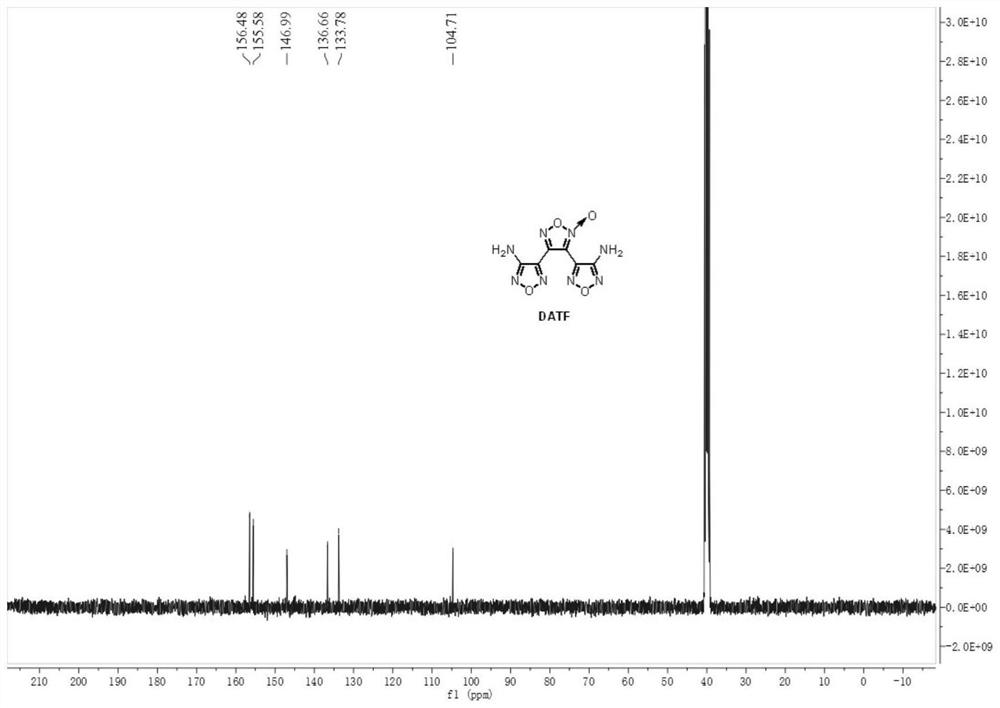

[0040] Weigh 1.43g (10mmol, 1.0equiv) of 3-amino-4-amidoxime furazan (AAOF), add 14mL water and 6mL concentrated hydrochloric acid (37%) respectively, stir and dissolve it fully, use it as material Ⅰ, and draw it with a syringe Then place it on the syringe pump; Weigh 0.69g of sodium nitrite (NaNO 2 , 10mmol, 1.0equiv) after adding appropriate distilled water and fully stirring to dissolve, it was prepared into a 10mL solution as material II, which was sucked with a syringe and placed on the syringe pump; next, 0.3mol / L Na 2 CO 316mL of the solution, as material III, was drawn up with a syringe and placed on the syringe pump. After the feed pump is set at an appropriate flow rate, it pumps in material I and material II at the same time, and after being fully mixed, the materials are transported to the microflow field reaction module 1 for reaction. Among them, the internal diameter of the pipeline used in the micro-flow field reaction module 1 is 1.5mm, the length is 10m, an...

Embodiment 2

[0042] Weigh 1.43g (10mmol, 1.0equiv) of 3-amino-4-amidoxime furazan (AAOF), add 14mL water and 6mL concentrated hydrochloric acid (37%) respectively, stir and dissolve it fully, use it as material Ⅰ, and draw it with a syringe Then place it on the syringe pump; weigh 0.69g NaNO 2 (10mmol, 1.0equiv) was dissolved with an appropriate amount of distilled water, and prepared into a 10mL solution as material II, which was sucked with a syringe and placed on a syringe pump; measure 0.3mol / L of Na 2 CO 3 16 mL of the solution was used as material III. After the feed pump is set at an appropriate flow rate, it pumps in material I and material II at the same time, mixes them and transports them to the microflow field reaction module 1 for reaction. Among them, the inner diameter of the pipeline of the micro-flow field reaction module 1 is 2.0mm, the length of the tube is 6m, and the volume is 18.4mL. / min, the reaction residence time is 2.5min. Then the material III is pumped in t...

Embodiment 3

[0044] Weigh 1.43g (10mmol, 1.0equiv) of 3-amino-4-amidoxime furoxan (AAOF), add 14mL of water and 6mL of concentrated hydrochloric acid (37%) to fully stir and dissolve respectively, and use it as material Ⅰ. Place it on the syringe pump; weigh 0.69g NaNO 2 (10mmol, 1.0equiv) was dissolved in appropriate distilled water to prepare a 10mL solution, as material Ⅱ, suck it up with a syringe and put it on the syringe pump; after sucking it up with a syringe, put it on the syringe pump; 2 CO 3 16mL of the solution, as material III, was drawn up with a syringe and placed on the syringe pump. After the feed pump is set at an appropriate flow rate, it pumps in material I and material II at the same time, mixes them and transports them to the microflow field reaction module 1 for reaction. Among them, the microflow field reaction module 1 has an inner diameter of 1.0mm, a length of 20m, a volume of 15.7mL, and a reaction temperature of 20°C; the flow rate of material I is 5.0mL / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com