Preparation method of fiber-reinforced phenolic resin composite material and fiber-reinforced phenolic resin composite material

A phenolic resin and composite material technology, which is applied in the preparation of fiber-reinforced phenolic resin composite materials and the field of fiber-reinforced phenolic resin composite materials, can solve the problems of reducing material density, strong rigidity and poor flexibility, and achieves improved flexibility and low cost. , Improve the effect of strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

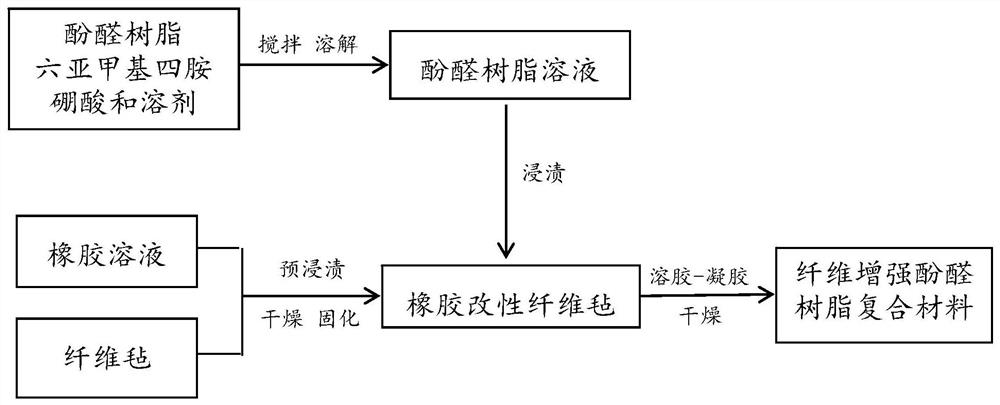

[0035] According to the first aspect of the present invention, the present invention provides a kind of preparation method of fiber-reinforced phenolic resin composite material, comprises the following steps:

[0036] Step A: prepare toughening agent solution and phenolic resin solution;

[0037] Step B: pre-impregnating the fiber mat with the toughening agent solution, drying and curing to obtain the toughening agent modified fiber mat;

[0038] Step C: impregnating the toughening agent-modified fiber mat with a phenolic resin solution, and drying to obtain a fiber-reinforced phenolic resin composite material.

[0039] Phenolic resin refers to a high polymer obtained by polycondensation of phenol and aldehyde or its derivatives. The most important feature of phenolic resin is high temperature resistance, even at very high temperatures, it can maintain its structural integrity and dimensional stability. It is for this reason that phenolic resins are used in some high-tempera...

Embodiment 1

[0086] This embodiment provides a carbon fiber reinforced phenolic resin composite material, specifically comprising the following steps:

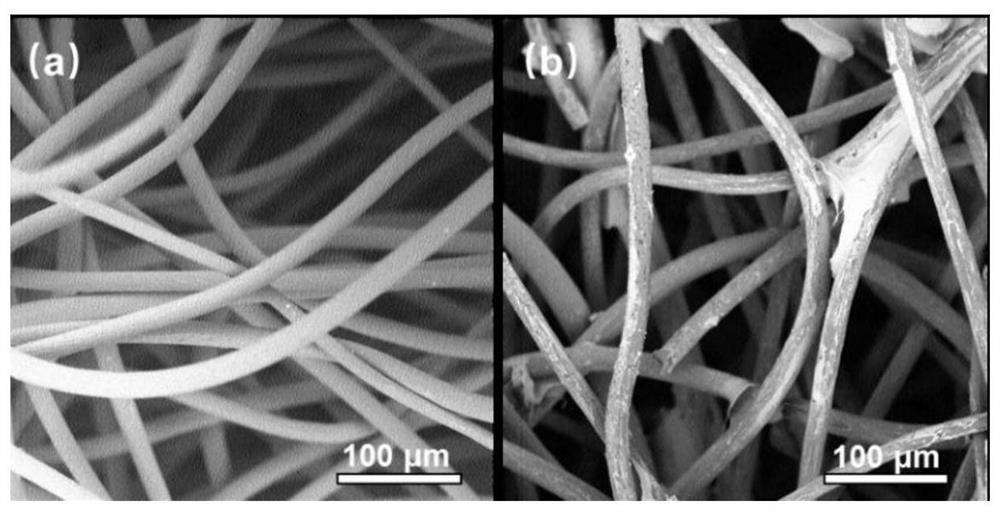

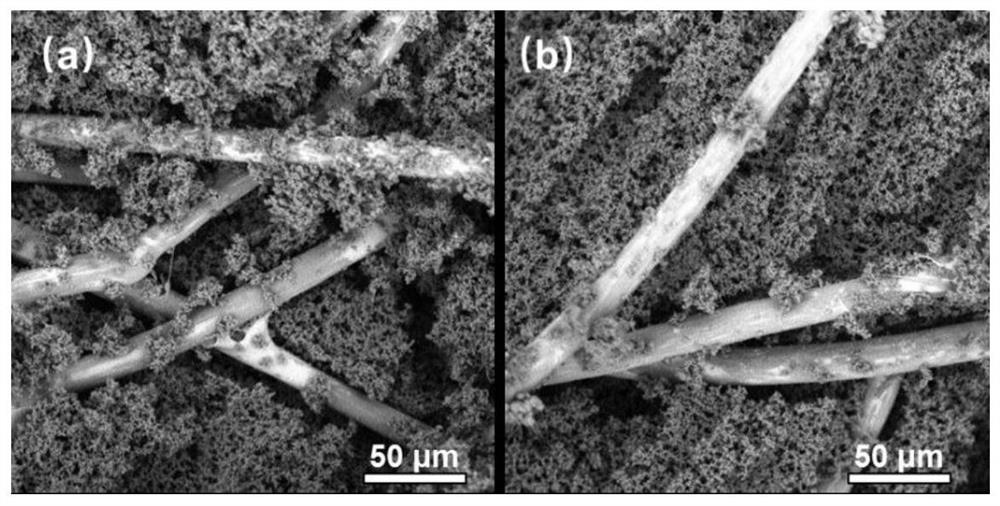

[0087] (1) Cut a carbon fiber felt with a thickness of 10mm into a size of 150*150mm, place it in an oven at 80°C to dry for a certain period of time, take it out, and place it in a stainless steel mold; weigh a certain amount of natural rubber latex, and prepare a natural rubber latex with a mass concentration of 2%. The rubber solution was poured into a stainless steel mold, and the carbon fiber felt was pre-impregnated under normal pressure; after full impregnation, the mold was placed in an oven at 80°C, and after drying and curing for 12 hours, a natural rubber modified carbon fiber felt was obtained.

[0088] (2) Weigh a certain amount of phenolic resin, hexamethylenetetramine and boric acid respectively, add them into a reaction kettle containing a certain amount of isopropanol solvent, and stir mechanically until completely dissolve...

Embodiment 2

[0090] This embodiment provides a carbon fiber reinforced phenolic resin composite material, specifically comprising the following steps:

[0091] (1) Cut a carbon fiber felt with a thickness of 10mm into a size of 150*150mm, place it in an oven at 80°C to dry for a certain period of time, take it out, and place it in a stainless steel mold; weigh a certain amount of natural rubber latex, and prepare a natural rubber latex with a mass concentration of 4%. The rubber solution was poured into a stainless steel mold, and the carbon fiber felt was pre-impregnated under normal pressure; after full impregnation, the mold was placed in an oven at 80°C, and after drying and curing for 12 hours, a natural rubber modified carbon fiber felt was obtained.

[0092] (2) Weigh a certain amount of phenolic resin, hexamethylenetetramine and boric acid respectively, add them into a reaction kettle containing a certain amount of isopropanol solvent, and stir mechanically until completely dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com