A kind of high-hardness corrosion-resistant coating and its preparation method and application

A corrosion-resistant coating, high-hardness technology, applied in coatings, metal material coating processes, electrochemical generators, etc., can solve the problem of difficult to meet the corrosion resistance requirements of fuel cell metal bipolar plates, and achieve a crystal structure. Perfect, improve corrosion resistance, excellent corrosion resistance and stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing the high-hard corrosion-resistant coating described in the above technical solution, comprising the following steps:

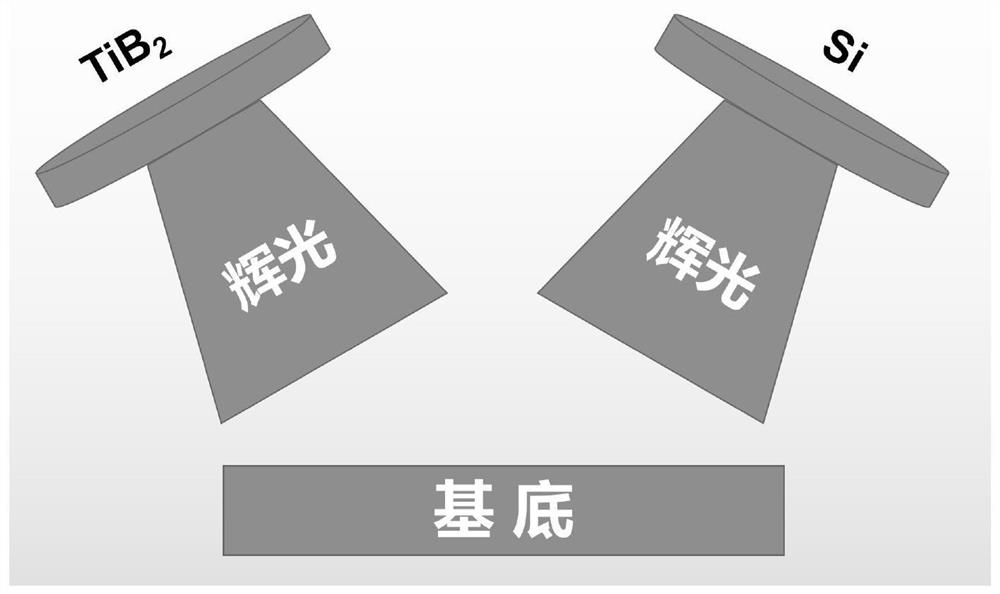

[0025] in TiB 2 The target and the Si target are target materials, and the high-hardness corrosion-resistant coating is obtained by sputtering on the substrate surface by using a magnetron sputtering method.

[0026] In the present invention, the TiB 2 The purity of the target is preferably 99 to 99.99%; the TiB 2 The target is preferably a cylinder with a diameter of preferably 40-80 mm, more preferably 60 mm, and a thickness of 5 mm. In the present invention, the TiB 2 The target is preferably subjected to pre-sputtering to remove impurities such as oxides on the surface of the target. In the present invention, the pre-sputtering is preferably carried out under the condition of argon atmosphere, when the pre-sputtering is TiB 2 The power of the target is preferably 100W, and the time is p...

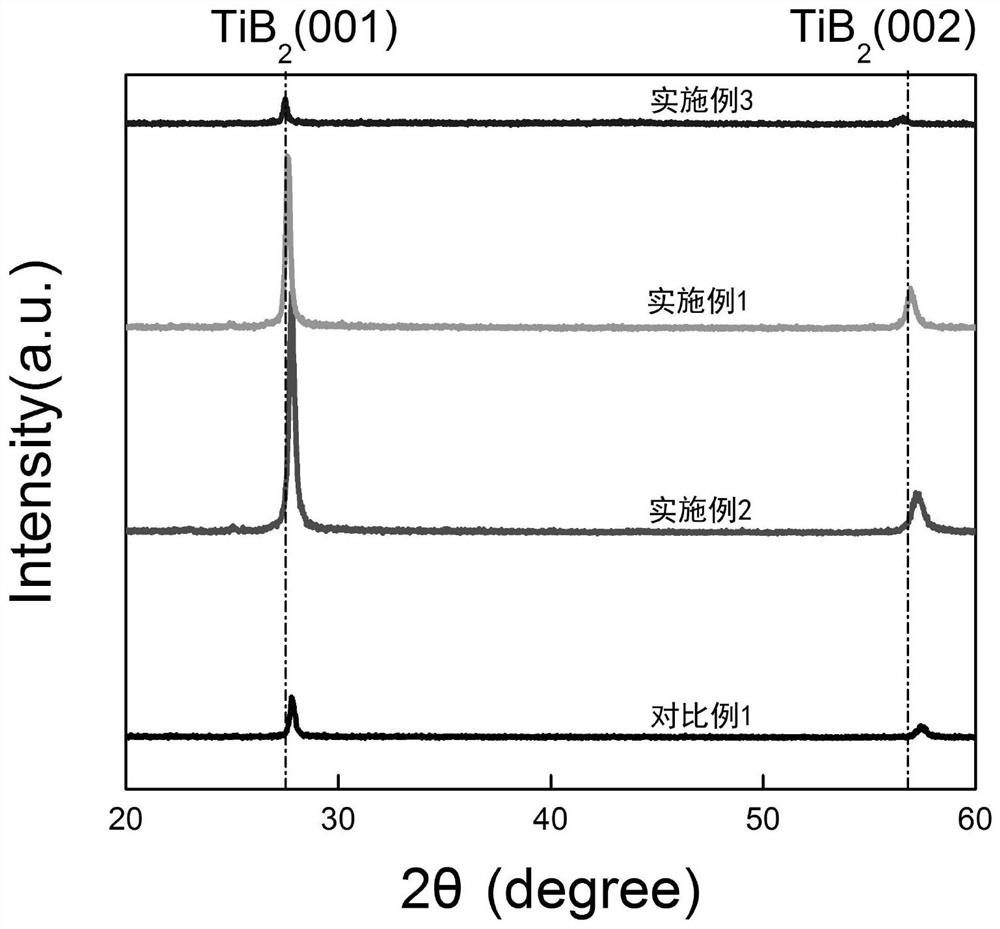

Embodiment 1

[0040] Substrate pretreatment: Before loading the single crystal Si(100) substrate and polished titanium foil into the coating chamber, they should be ultrasonically cleaned, and the single crystal Si(100) substrate and polished titanium foil should be placed in acetone, ethanol, etc. and deionized water for 15 minutes after ultrasonication, and each step was dried with nitrogen to obtain a substrate with a clean surface;

[0041] Place the target and evacuate the coating chamber: TiB 2 Put the target and Si target into the target platform, then put the single crystal Si (100) substrate and polished titanium foil into the sample tray, close the coating chamber, close the air release valve, and then use the mechanical pump and the molecular pump to reduce the pressure of the coating chamber to Draw up to 6×10 -5 Pa;

[0042] Pre-sputtering: Before sample preparation begins, TiB 2 The target and the Si target were sputtered in an argon atmosphere for 20 minutes; during sputte...

Embodiment 2

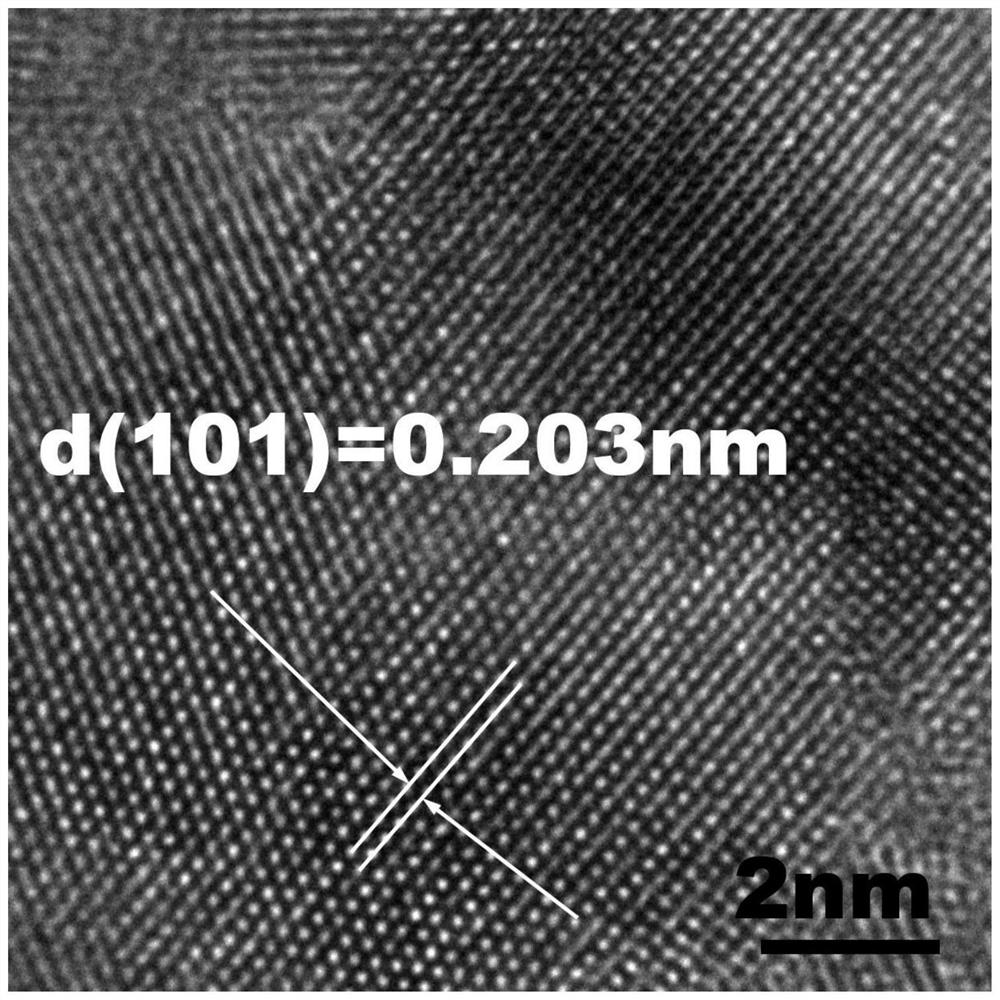

[0046] The preparation method is basically the same as that of Example 1, except that the power of the Si target is 20W. The atomic content of Si in the obtained high-hard corrosion-resistant coating is 3%, the atomic content of Ti is 31%, and the atomic content of B is 66%; The potential is 0.11V, and the self-corrosion current is 9×10 -7 A / cm 2 , AC impedance is 5×10 4 Ω / cm 2 ; Its resistivity remains at 1176μΩ·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com