Preparation method of room-temperature semiconductor gas sensing material and sensor

A gas sensor and gas sensing technology, applied in the field of gas sensing, can solve the problems of room temperature sensing performance decline, disappearance, no room temperature sensor finished products, etc., and achieve the effects of unique sensing performance, good composite, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

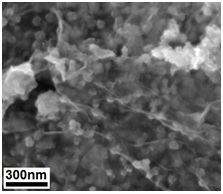

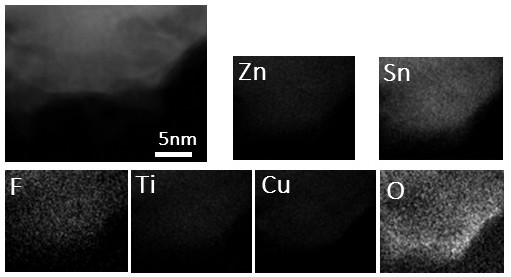

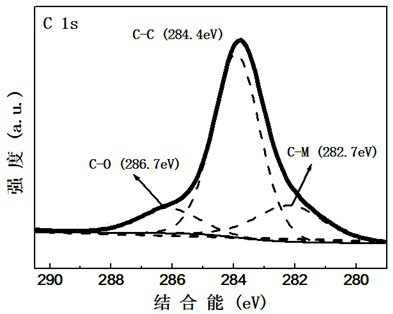

Image

Examples

Embodiment 1

[0029]A room temperature semiconductor gas sensor and a preparation method thereof. The preparation method includes the following steps:

[0030](1) Preparation of unit oxide nanomaterial precursor liquid. Unit oxide nanomaterials refer to oxide nanomaterials containing a metal element. The preparation process of the precursor liquid is as follows:

[0031]ZnO precursor liquid. Add 4.0g of ZnCl2In 5ml water, make solution 1; add 5.5g of Na2CO3To 35 ml of water, configure into solution 2; while stirring, slowly add solution 1 to solution 2 to form a ZnO precursor liquid.

[0032]F doped SnO2(SnO2:F) Precursor liquid. Weigh 9.5g of SnCl2• 2H2O, 0.04g of NaF, dissolved in 200ml of deionized water to prepare solution 1; measure 15ml of ammonia, add 120ml of deionized water to dilute to prepare solution 2; while stirring, slowly add solution 2 to solution 1 To form SnO2:F precursor liquid.

[0033]TiO2Precursor liquid. Measure 6.5ml of tetra-n-butyl titanate and dissolve it in 60ml of deionized wate...

Embodiment 2

[0045]A room temperature semiconductor gas sensor and a preparation method thereof. The preparation method includes the following steps:

[0046](1) Preparation of unit oxide nanomaterial precursor liquid.

[0047]ZnO precursor liquid. Add 4.6g of ZnCl2To 5ml water, make solution 1; add 6.1g of Na2CO3To 35 ml of water, configure into solution 2; while stirring, slowly add solution 1 to solution 2 to form a ZnO precursor liquid.

[0048]F doped SnO2Precursor liquid. Weigh 10.0g of SnCl2• 2H2O, 0.045g of NaF, dissolved in 200ml of deionized water to prepare solution 1; Measure 20ml of ammonia, add 120ml of deionized water to dilute to prepare solution 2; while stirring, slowly add solution 2 to solution 1 , The formation of F-doped SnO2Precursor liquid.

[0049]TiO2Precursor liquid. Measure 6ml of tetra-n-butyl titanate and dissolve it in 60ml of deionized water; transfer the above solution to a 100ml reactor and put it in a drying oven at 120°C for 5h for hydrothermal reaction; after the reactio...

Embodiment 3

[0057]A room temperature semiconductor gas sensor and a preparation method thereof. The preparation method includes the following steps:

[0058](1) Precursor liquid preparation of unit oxide nanomaterials, the preparation process is as follows:

[0059]ZnO precursor liquid. Add 5.0g of ZnCl2In 5ml water, make solution 1; add 6.5g of Na2CO3To 35 ml of water, configure into solution 2; while stirring, slowly add solution 1 to solution 2 to form a ZnO precursor liquid.

[0060]F doped SnO2(SnO2:F) Precursor liquid. Weigh 10.5g of SnCl2• 2H2O, 0.05g of NaF, dissolved in 200ml of deionized water to prepare solution 1; measure 25ml of ammonia, add 120ml of deionized water to dilute to prepare solution 2; while stirring, slowly add solution 2 to solution 1 To form SnO2:F precursor liquid.

[0061]TiO2Precursor liquid. Measure 5.5ml of tetra-n-butyl titanate and dissolve it in 60ml of deionized water; transfer the above solution to a 100ml reactor and put it in a drying oven at 120°C for 5h for hydrot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com