Experimental device and experimental method for researching ignition combustion process of modified aluminum powder

A technology of combustion process and experimental device, which is applied in the direction of chemical analysis and color/spectral property measurement using combustion, which can solve the problems of difficult collection of residues of combustion products after sample replacement, flow combustion of engines, etc., and achieves simple operation, easy parallel comparison, Safe and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

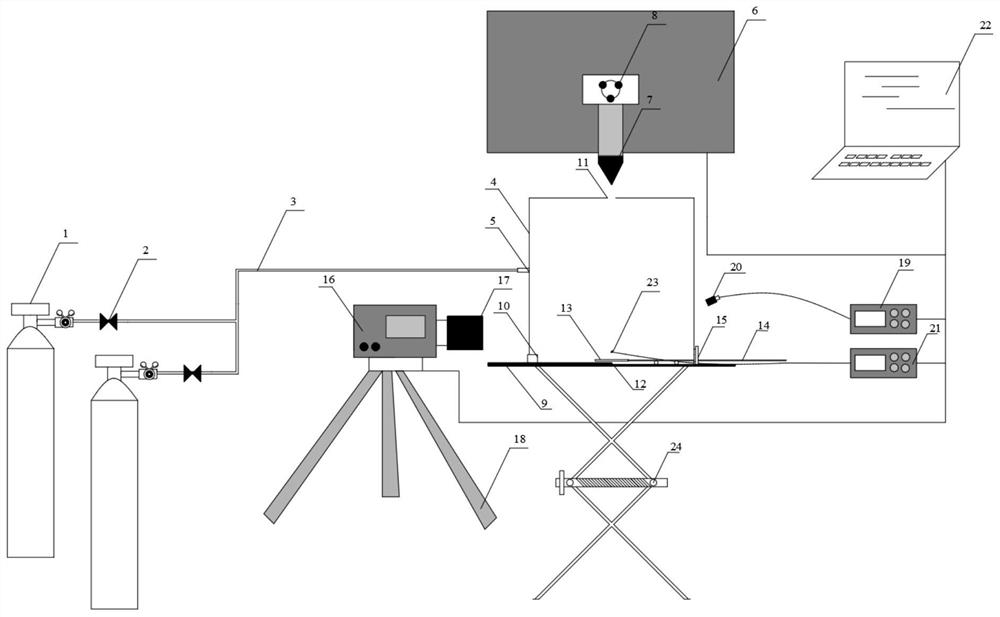

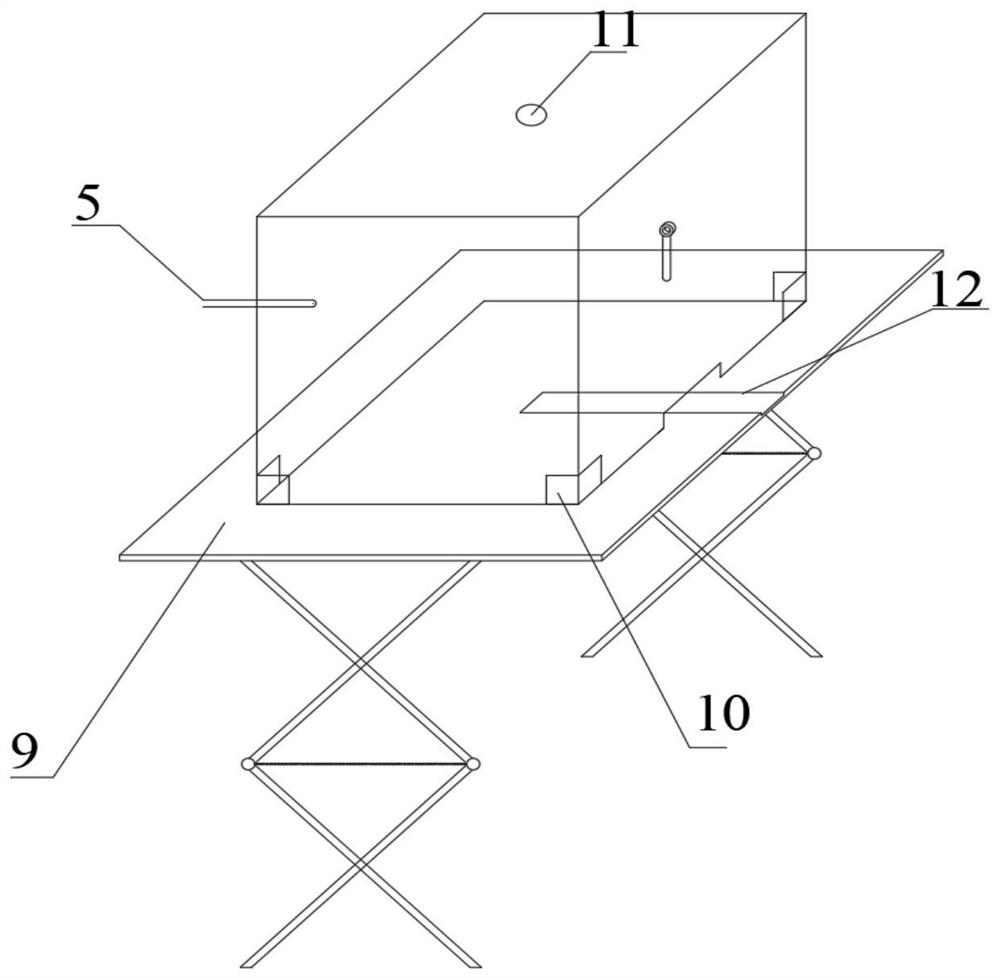

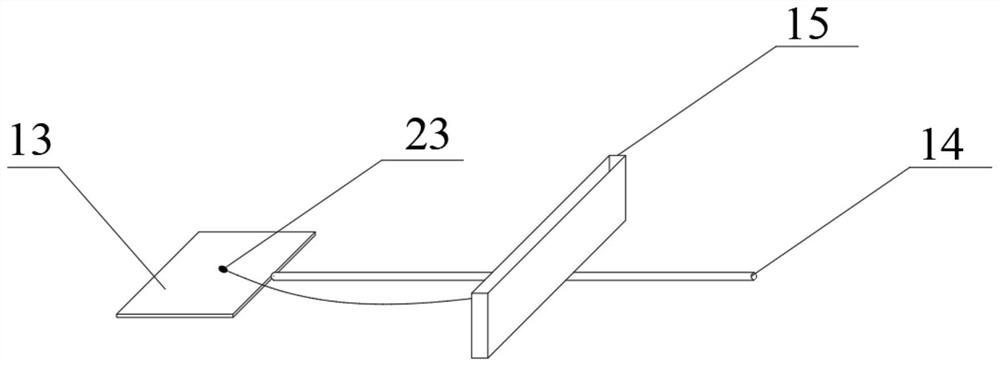

[0038] combine figure 1 , figure 2 , image 3 As shown, an experimental device for studying the combustion performance of modified aluminum powder in a non-air atmosphere combustion process in this embodiment includes a gas delivery device, an ignition device, a combustion chamber and a detection device.

[0039] The gas delivery device includes a high-pressure gas bottle 1 , a volume flow meter 2 , a gas delivery pipe 3 , and an air inlet 5 . The high-pressure gas bottle is used to store the combustion atmosphere needed in the experiment, and can be replaced according to the experiment requirements. In this example, carbon dioxide is used. The outlet of the high-pressure gas bottle 1 is connected to the volume flow meter 2, and the volume flow meter 2 detects the volume flow rate of the gas delivery. After the experiment starts, the high-pressure gas bottle 1 is opened, and the gas in the bottle passes through the volume flow meter 2 and then enters the combustion chamber...

Embodiment 2

[0045] An experimental device for studying the combustion performance of modified aluminum powder in a non-air atmosphere combustion process in this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that the sample placement area is replaced by a heat-resistant crucible, and the The argon (Ar) cylinder is used as a high-pressure gas cylinder 1 and is connected to the volume flow meter 2 and the gas delivery pipe to 3.

[0046] During use, take by weighing 100mg of aluminum / water-based high-energy fuel, place it in the ignition area, place the thermocouple 23 close to the sample combustion area, and send the sample pushing device 13 into the combustion chamber, then slowly open the high-pressure gas bottle 1 to Introduce Ar gas into the combustion chamber at a speed of 40ml / min for ten minutes, use the laser igniter 6 to ignite, and trigger the high-speed camera 16 and fiber optic spectrometer 19 to record the visual image of the combustion p...

Embodiment 3

[0048] An experimental device for studying the combustion performance of modified aluminum powder in a non-air atmosphere combustion process of this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that: the thermocouple 23 is placed close to the sample combustion area, and the thermocouple 23 passes through The slide rail groove 12 is connected with the temperature data acquisition instrument 21 and synchronized with the laser igniter 6 . The thermocouple type is K type.

[0049] When in use, weigh 50 mg of modified aluminum powder with 0%, 2%, 5%, 8% and 10% ammonium perchlorate (AP) respectively, use argon (Ar) as the combustion atmosphere, and use a high-speed camera after ignition 16. The optical fiber spectrometer 19 records the visual image of the combustion process and the spectral signal during the combustion process respectively, and the intensity of the spectral signal can be converted into the temperature during the combustion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com