Preparation method and application of Mo-doped HNb3O8 nanosheet

A nanosheet and reaction technology, applied in the field of photocatalysis, can solve the problems of large forbidden band width of pure niobate nanosheets, unsatisfactory visible light absorption, limiting the photocatalytic hydrogen production properties of niobic acid, etc., so as to reduce the recombination rate and enhance the visible light. Absorption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The Mo-doped HNb of this embodiment 3 o 8 The preparation method of nanosheet photocatalyst material is as follows:

[0034] (1) Dissolve 3 mmoles of niobium pentachloride (0.81g) in 36ml of absolute ethanol and stir for 30-60min to dissolve completely;

[0035] (2) Add 0.0303 millimoles of molybdenum pentachloride powder to the solution as a molybdenum source. At this time, Mo:Nb is 1:99, and then ultrasonically shake for 0.5-1 hour to completely dissolve it;

[0036] (3) Add 26mL of tetramethylammonium hydroxide aqueous solution with a mass fraction of 10% dropwise to the mixed solution at a rate of 0.8mL / min to react, and stir until a clear solution is formed. At this time (molybdenum pentachloride + pentachloride Niobium chloride) and the molar ratio of tetramethylammonium hydroxide is 1:9.56;

[0037] (4) Afterwards, the obtained solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and placed in a constant temperature...

Embodiment 2

[0040] The Mo-doped HNb of this embodiment 3 o 8 The preparation method of nanosheet photocatalyst material is as follows:

[0041] (1) Dissolve 3 mmoles of niobium pentachloride (0.81g) in 36ml of absolute ethanol and stir for 30-60min to dissolve completely;

[0042] (2) Add 0.158 millimoles of molybdenum pentachloride powder to the solution. At this time, Mo:Nb is 1:19, and then ultrasonically shake for 0.5-1 hour to completely dissolve it;

[0043](3) Add 26mL of tetraethylammonium hydroxide aqueous solution with a mass fraction of 16.05% dropwise to the mixed solution at a rate of 1mL / min for reaction, and stir until a clear solution is formed. At this time (molybdenum pentachloride + pentachloride The molar ratio of niobium chloride) to tetraethyl hydroxide is 1:9.18;

[0044] (4) Afterwards, the obtained solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and placed in a constant temperature drying oven for heating reacti...

Embodiment 3

[0047] The Mo-doped HNb of this embodiment 3 o 8 The preparation method of nanosheet photocatalyst material is as follows:

[0048] (1) Dissolve 3 mmoles of niobium pentachloride (0.81g) in 36ml of absolute ethanol and stir for 30-60min to dissolve completely;

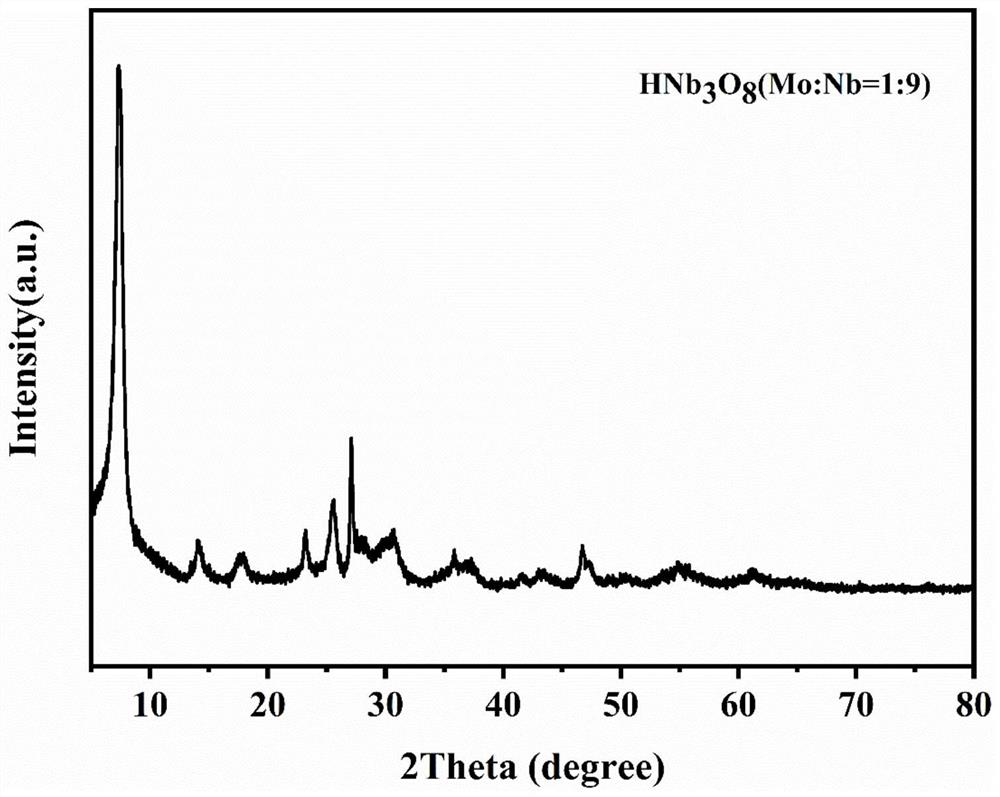

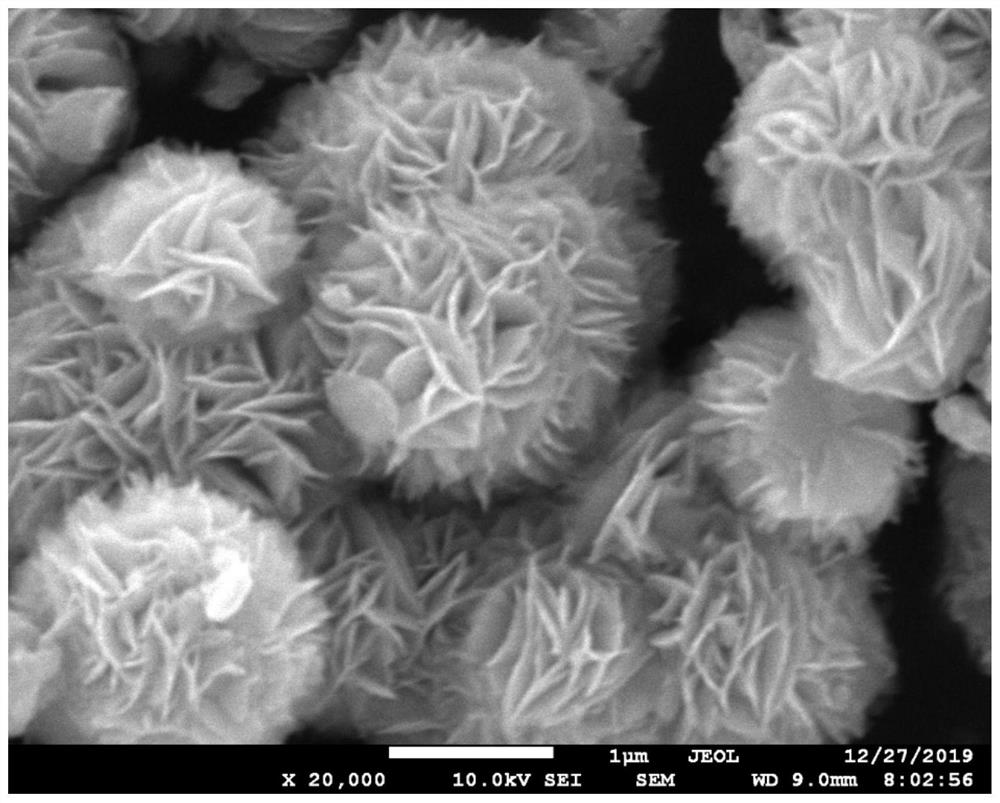

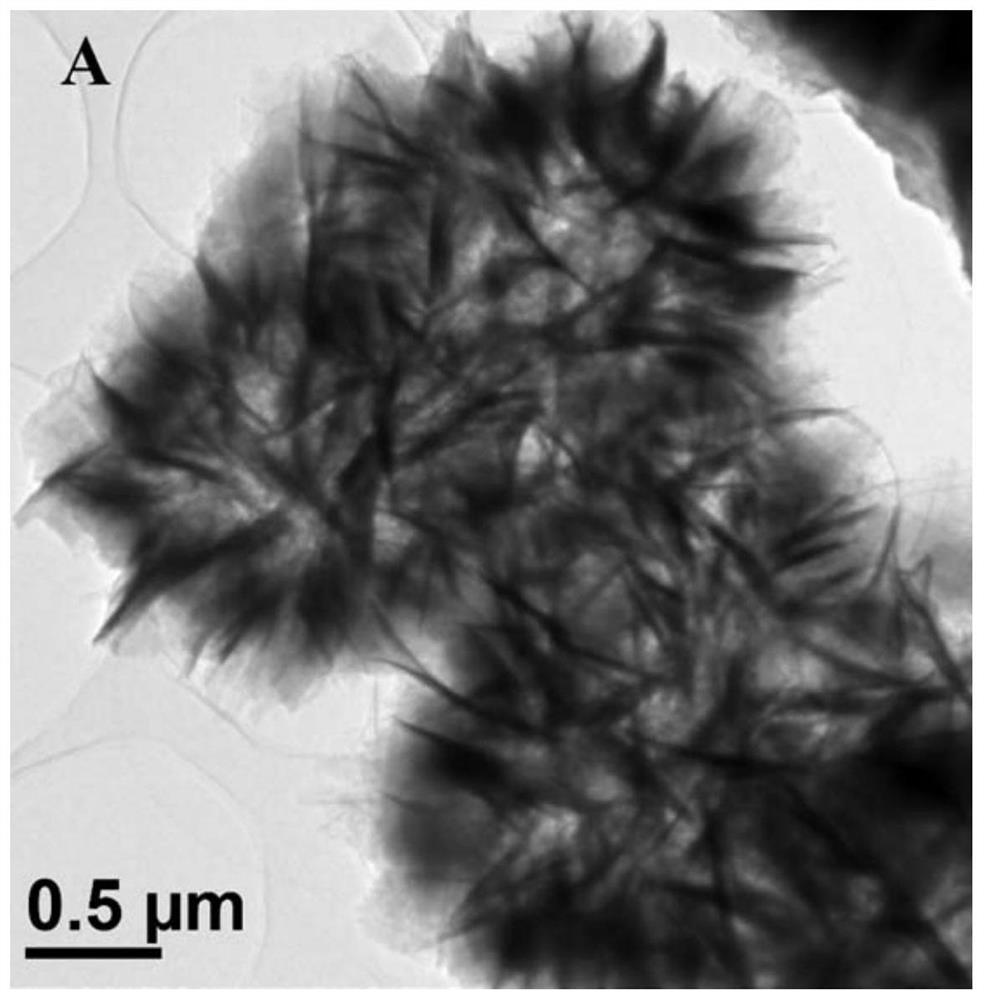

[0049] (2) Add 0.333 millimoles of molybdenum pentachloride powder to the solution. At this time, Mo:Nb is 1:9, and then ultrasonically shake for 30-60 minutes to completely dissolve it;

[0050] (3) Add 26mL of tetramethylammonium hydroxide aqueous solution with a mass fraction of 10% dropwise to the mixed solution at a rate of 0.6 mL / min to react, and stir until a clear solution is formed. At this time (molybdenum pentachloride + pentachloride Niobium chloride) and the molar ratio of tetramethylammonium hydroxide is 1:8.69;

[0051] (4) Afterwards, the obtained solution was transferred to a stainless steel reaction kettle lined with polytetrafluoroethylene, and placed in a constant temperature drying oven for heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com