Method suitable for assembling and reconstructing tiny objects on fluid interface and application of method

A fluid interface, object technology, applied in chemical instruments and methods, liquid/fluid solid measurement, fluid velocity measurement using thermal variables, etc., can solve the structure that cannot be reconfigured and assembled, the application limitations of temperature changes, and the assembly form is difficult to freely adjust and other problems, to achieve the effect of rich and variable assembly patterns and wide application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

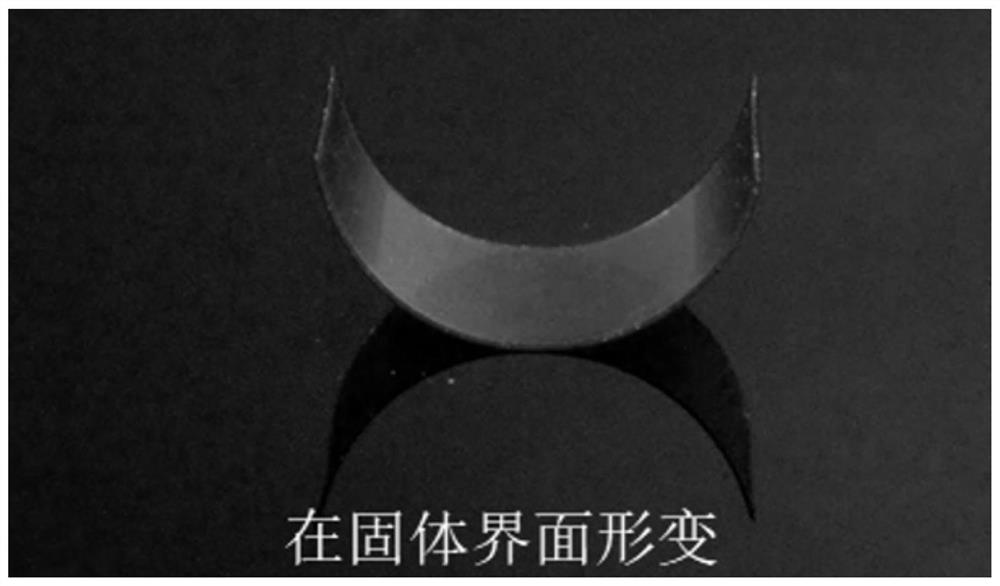

[0054] Preparation Example 1: The liquid crystal polymer film was prepared by the photopolymerization method in the in-situ polymerization method. First, mix C9A and DA11AB6 in a molar ratio of 78:20, and then add 2% photoinitiator. After mixing evenly, pour it into a liquid crystal cell made of two substrates. The substrate is coated with an orientation-treated polyimide film, and a spacer material with a certain diameter is placed between the two substrates to maintain a certain distance so as to control the thickness of the liquid crystal polymer composite film. Use a hot stage to control the temperature at 95°C, and when the wavelength emitted by the light source is greater than 550nm, the light intensity is 16mW / cm 2 The reaction was carried out for 6 hours under the light of sunlight, and then the liquid crystal cell was opened to obtain a liquid crystal polymer composite film. Cut the liquid crystal polymer film into various shapes to obtain micro-actuators.

[0055]...

Embodiment 1

[0056] Example 1: Assembly and reconstruction of light-controlled two rectangular micro-actuators:

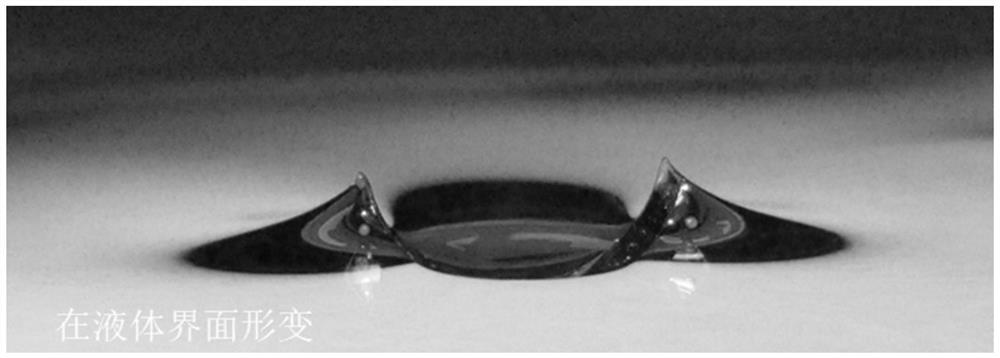

[0057] Place the two strip-shaped micro-actuators (6mm×2mm×0.03mm in size) obtained in Preparation Example 1 on the air-water interface, and respectively irradiate them with ultraviolet light sources, wherein the light intensity of the ultraviolet light sources is 150-200mW cm -2 .

[0058] Result: if figure 2 Shown:

[0059] 1. When two micro-actuators are bent upward at the same time, the micro-actuators are assembled together in the form of multiple heads or side by side.

[0060] 2. When two micro-actuators are bent downward at the same time, the micro-actuators are assembled together in the form of multiple heads or side by side.

[0061] 3. When one micro-actuator is bent upwards and the other is bent downwards, the micro-actuators are assembled together in a "T" fashion.

Embodiment 2

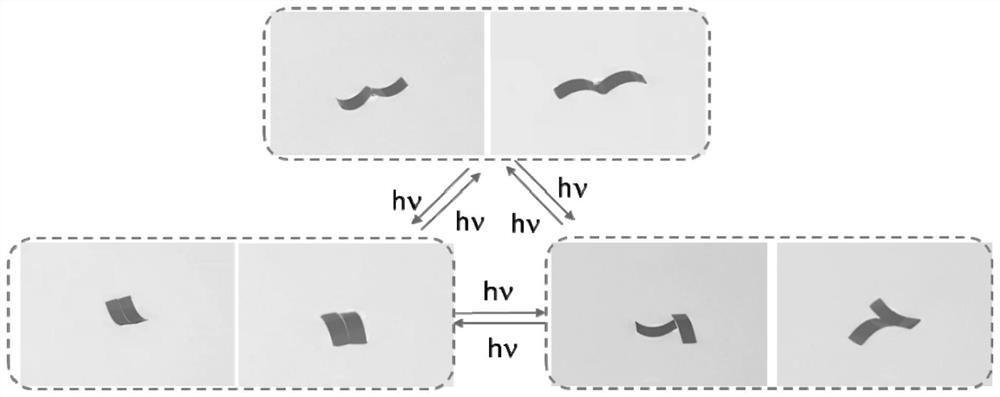

[0062] Example 2: Assembly and reconstruction of light-controlled three rectangular micro-actuators:

[0063] Repeat the experiment of Example 1, the difference is that three micro-actuators are placed on the liquid surface at the same time, and the assembly pattern is formed by irradiating with ultraviolet light, and further using visible light to return some actuators to the initial state, and then adjusting the irradiation direction of the ultraviolet light source can be adjusted. Assemble the pattern for reconstruction. .

[0064] Result: if image 3 As shown, when three actuators are assembled, nine different assembly patterns can be obtained by adjusting the irradiation direction of the light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com