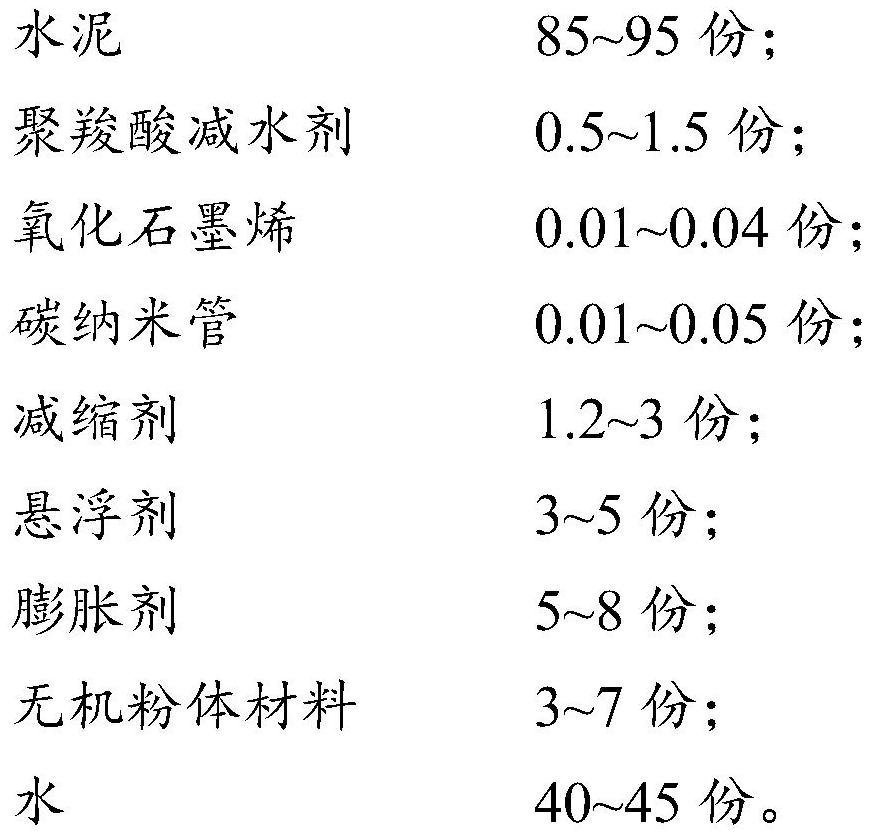

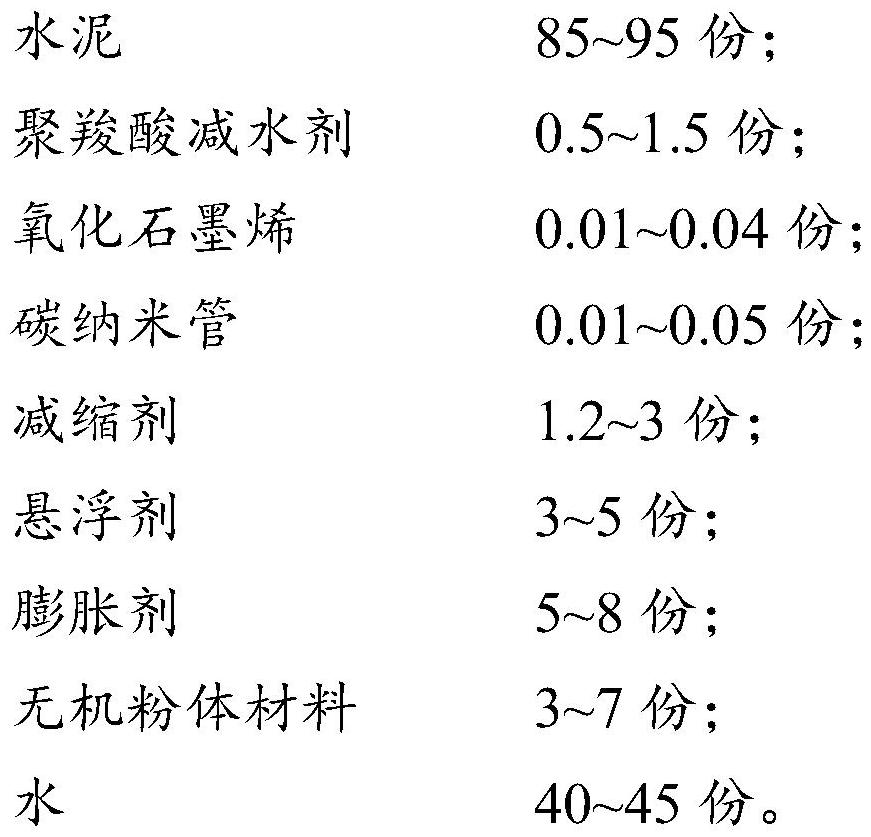

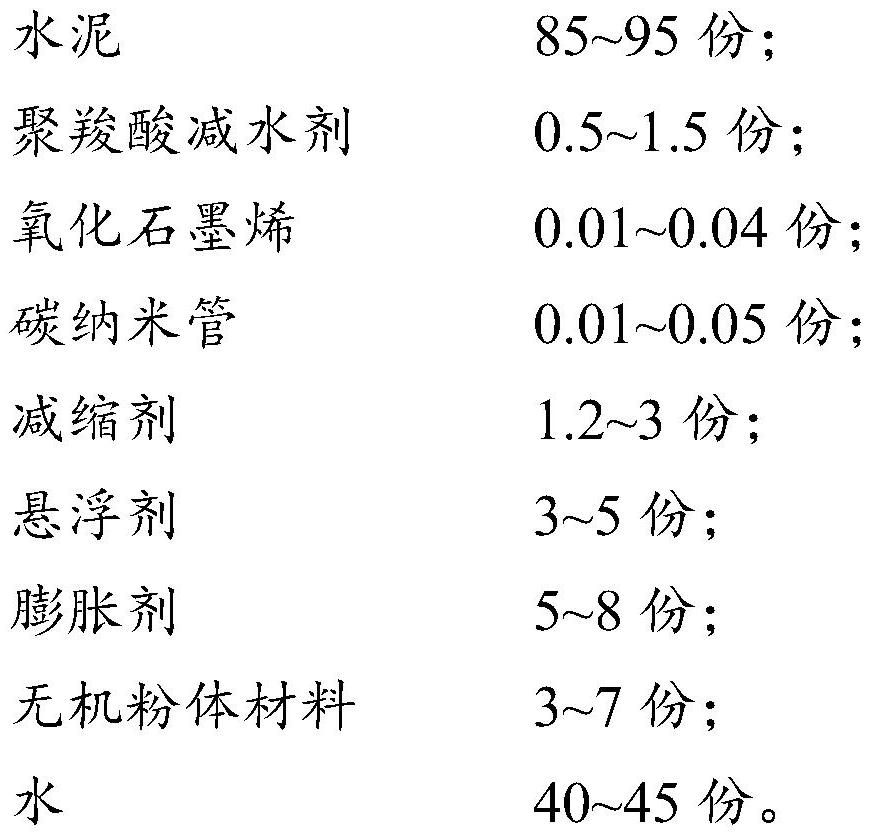

Graphene oxide nano-modified cement-based grouting material and preparation method thereof

A grouting material and nano-modification technology, which is applied in the field of cement-based grouting materials, can solve problems such as penetration, shortened service life, and performance degradation of cement-based grouting materials, so as to improve water-reducing rate, prolong service life, reduce The effect of internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]The invention also provides a method for preparing the graphene oxide nano-modified cement-based grouting material, which comprises the following steps:

[0044]1) Refining cement, carbon nanotubes, suspending agent and expansion agent to obtain dry material;

[0045]2) Mixing the dry material, polycarboxylic acid water reducing agent, inorganic powder material and part of water to obtain a slurry;

[0046]3) Mixing the slurry, graphene oxide, shrinkage reducing agent and remaining water to obtain a graphene oxide nano-modified cement-based grouting material.

[0047]The particle size of the dry material in step 1) of the present invention is preferably ≤80 μm, more preferably ≤75 μm.

[0048]In step 2) of the present invention, the part of the water is preferably 60 to 80% of the total mass of water, more preferably 65 to 75%, more preferably 70%; the mixing time is preferably 3 to 6 minutes, more preferably 4 ~5min.

[0049]The mixing time in step 3) of the present invention is preferably 1 t...

Embodiment 1

[0052]8.5 kg of Portland cement, 0.001 kg of carbon nanotubes, 0.3 kg of sodium bentonite and 0.5 kg of calcium sulfoaluminate powder were ground to obtain a dry material with a particle size of 80 μm. The obtained dry material, 0.05 kg of polycarboxylic acid water reducing agent, 0.3 kg of quartz sand (with a particle size of 800 mesh) and 2.5 kg of water are mixed for 3 minutes to obtain a slurry. The obtained slurry, 0.001 kg of graphene oxide with an oxygen content of 21% (sheet thickness of 5 nm, length and width are both 100 nm), 0.12 kg of fatty alcohol polyoxyethylene ether and 2 kg of water were mixed for 1.5 minutes to obtain oxidation Graphene nano-modified cement-based grouting material.

[0053]The graphene oxide nano-modified cement-based grouting material of Example 1 was cured for 7d and 28d and then tested for performance. The 7d compressive strength was 59MPa, the 7d flexural strength was 8.1MPa; the 28d compressive strength was 85MPa, and the 28d flexural strength 14...

Embodiment 2

[0055]9.5 kg of Portland cement, 0.005 kg of carbon nanotubes, 0.5 kg of sodium bentonite and 0.8 kg of calcium sulfoaluminate powder were ground to obtain a dry material with a particle size of 75 μm. The obtained dry material, 0.15 kg of polycarboxylic acid water reducing agent, 0.3 kg of quartz sand (with a particle size of 600 mesh), 0.3 kg of heavy calcium powder (with a particle size of 600 mesh) and 3.5 kg of water are mixed for 6 minutes to obtain a slurry. Mix the obtained slurry, 0.004kg of graphene oxide with 25% oxygen content (sheet thickness of 7nm, length and width of 300nm), 0.3kg of diethylene glycol monobutyl ether and 0.8kg of water for 3min to obtain Graphene oxide nano-modified cement-based grouting material.

[0056]The graphene oxide nano-modified cement-based grouting material of Example 2 was cured for 7d and 28d and then tested for performance. The 7d compressive strength was 60MPa, the 7d flexural strength was 8.0MPa; the 28d compressive strength was 88MPa, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com