A lead-free ceramic dielectric with high energy storage density and high energy storage efficiency and preparation method thereof

A high energy storage density, ceramic dielectric technology, applied in chemical instruments and methods, ceramic molding machines, ceramic layered products, etc., can solve the limitations of miniaturization, integration and high performance of lead-free electronic components, breakdown The electric field strength and the maximum polarization strength are difficult to improve at the same time, and the energy storage efficiency is low, so as to achieve the effect of simple and convenient preparation method, high volatility and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

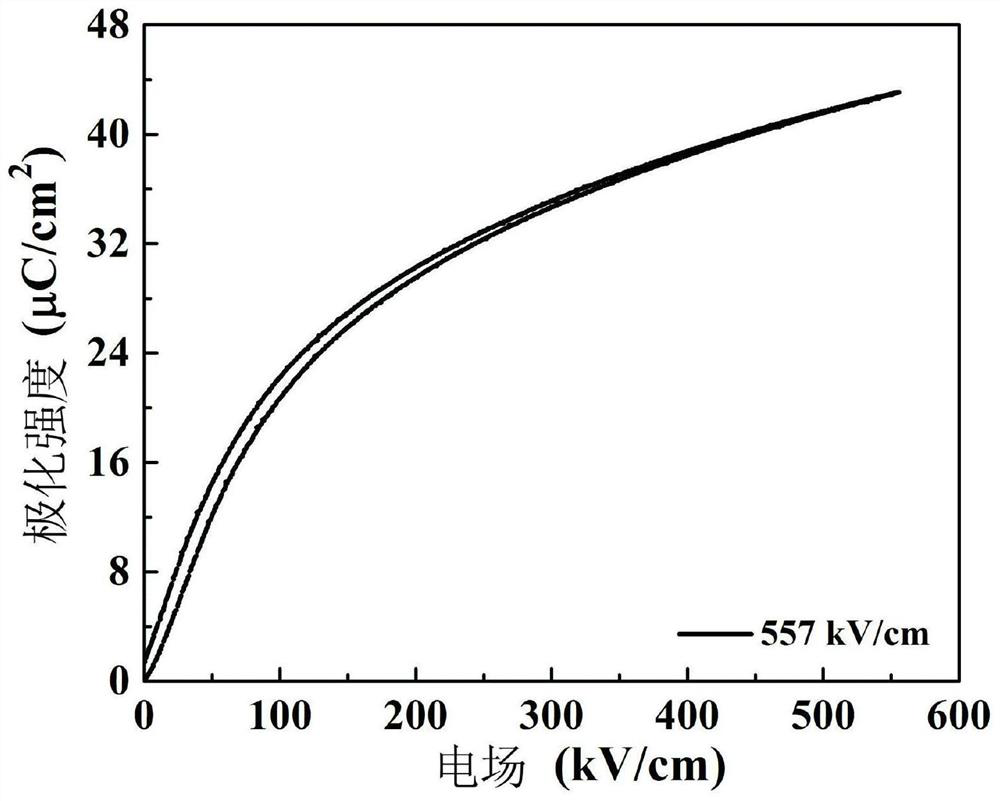

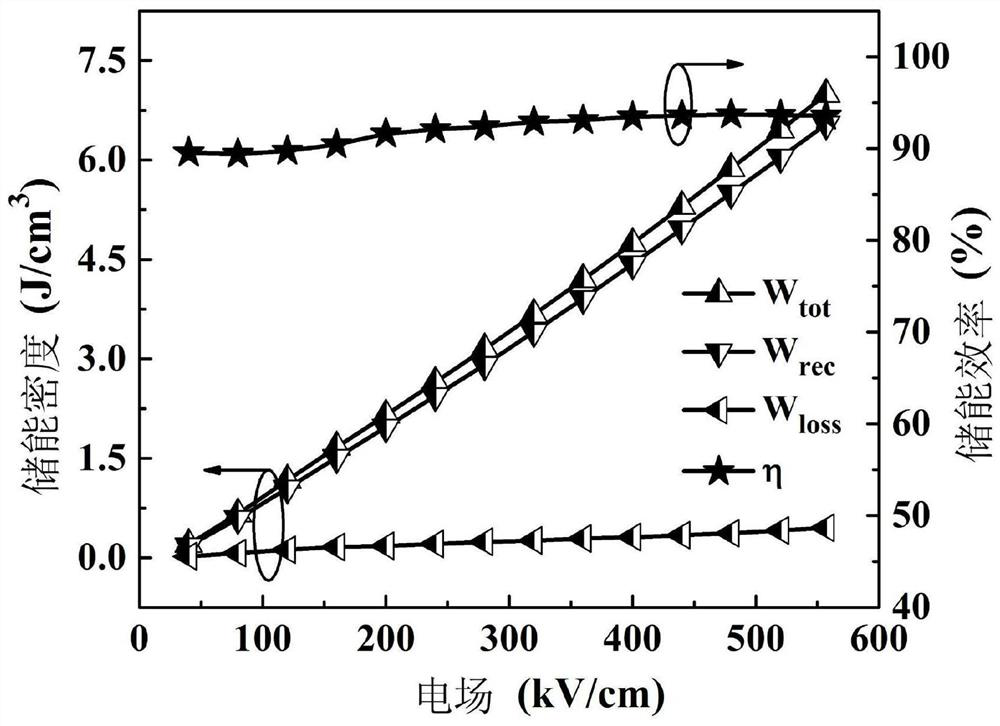

Embodiment 1

[0067] A lead-free high energy density and high energy efficiency of a ceramic dielectric (hereinafter referred to as dielectric ceramics) Preparation method:

[0068] To step S1, in accordance with the formula 0.80Bi 0.5 NA 0.5 TiO 3 -0.20srnb 0.5 Al 0.5 O 3 (Hereinafter referred to as BNTSNA) Weigh 14.3964g Bi 2 O 3 , 3.2484g Na 2 CO, 4.5612g SrCO 3 , 9.9714g TiO 2 , 0.7797g Al 2 O 3 And 2.0428gNb 2 O 5 As the raw dielectric material was prepared outer electrically, and then according to the formula 0.94Bi 0.55 NA 0.45 TiO 3 -0.06batio 3 (Hereinafter referred to as BNBT) Weigh 40.9673g Bi 2 O 3 , 7.5632g Na 2 CO 3 , 4.0271g BaCO 3 , 27.4423g TiO 2 As the raw dielectric material was prepared an inner layer electrically;

[0069] Step S2, the raw material and the inner layer an outer layer of dielectric material of the dielectric material were placed in two ball mill jar, then add ethanol and ZrO each mill pot in two 2 Ball as milling media, ZrO 2 Ball mass ratio of the two materi...

Embodiment 2

[0080] A process for preparing lead-free high storage density and storage efficiency of the ceramic dielectric:

[0081] To step S1, in accordance with the formula 0.94Bi 0.55 NA 0.45 TiO 3 -0.06BaTiO 3 (Hereinafter referred to as BNBT) Weigh 40.9673g Bi 2 O 3 , 7.5632g Na 2 CO 3 , 4.0271g BaCO 3 , 27.4423g TiO 2 As the raw dielectric material was prepared outer electrically, and then according to the formula 0.80Bi 0.5 NA 0.5 TiO 3 -0.20SrNb 0.5 Al 0.5 O 3 (Hereinafter referred to as BNTSNA) Weigh 14.3964gBi 2 O 3 , 3.2484g Na 2 CO, 4.5612g SrCO 3 , 9.9714g TiO 2 , 0.7797g Al 2 O 3 And 2.0428g Nb 2 O 5 As the raw dielectric material was prepared an inner layer electrically;

[0082] Step S2, the raw material and the inner layer an outer layer of dielectric material of the dielectric material were placed in two ball mill jar, then add ethanol and ZrO each mill pot in two 2 Ball as milling media, ZrO 2 Ball mass ratio of the two materials is 2: 1, by mass ethanol ratio of the two mat...

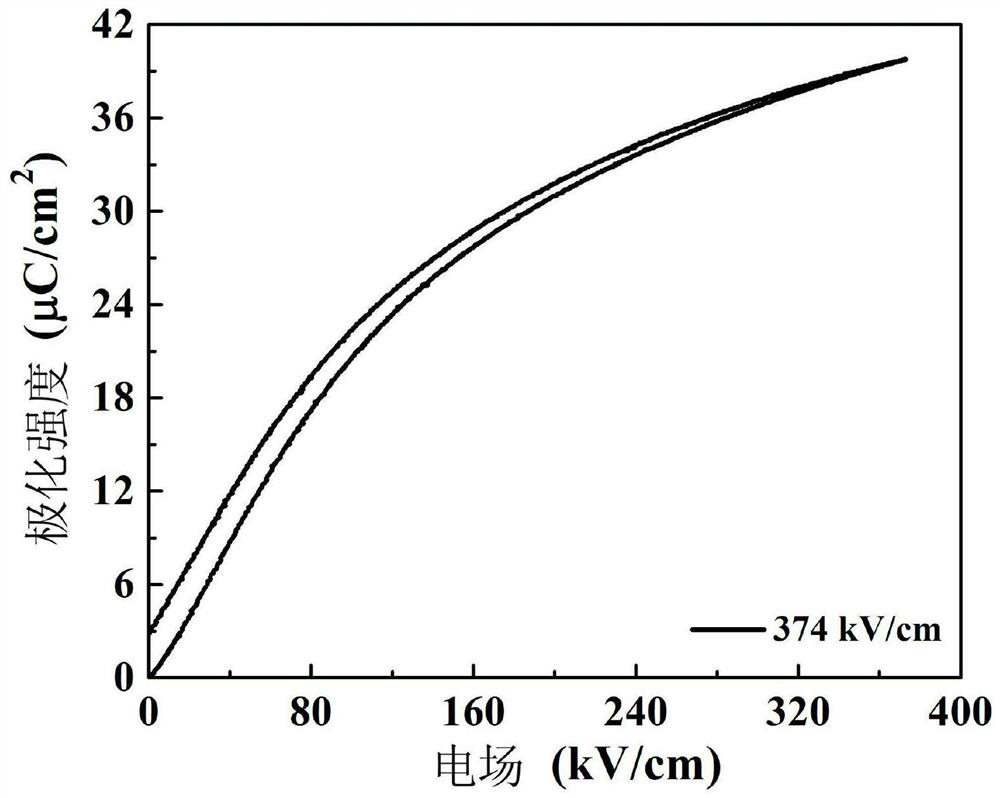

Embodiment 3

[0093] A process for preparing lead-free high storage density and storage efficiency of the ceramic dielectric:

[0094] To step S1, in accordance with the formula 0.80Bi 0.5 NA 0.5 TiO 3 -0.20SrNb 0.5 Al 0.5 O 3 (Hereinafter referred to as BNTSNA) Weigh 14.3964g Bi 2 O 3 , 3.2484g Na 2 CO, 4.5612g SrCO 3 , 9.9714g TiO 2 , 0.7797g Al 2 O 3 And 2.0428gNb 2 O 5 As the raw dielectric material was prepared outer electrically, and then according to the formula 0.75Bi 0.52 NA 0.48 TiO 3 -0.25SrTiO 3 (Hereinafter referred to as BNST) Weigh 15.9842g Bi 2 O 3 , 3.3293g Na 2 CO 3 , 6.4927g SrCO 3 , 14.1939g TiO 2 As the raw dielectric material was prepared an inner layer electrically;

[0095] Step S2, the raw material and the inner layer an outer layer of dielectric material of the dielectric material were placed in two ball mill jar, then add ethanol and ZrO each mill pot in two 2 Ball as milling media, ZrO 2 Ball mass ratio of the two materials are 1.5: 1, and ethanol by mass ratio of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com