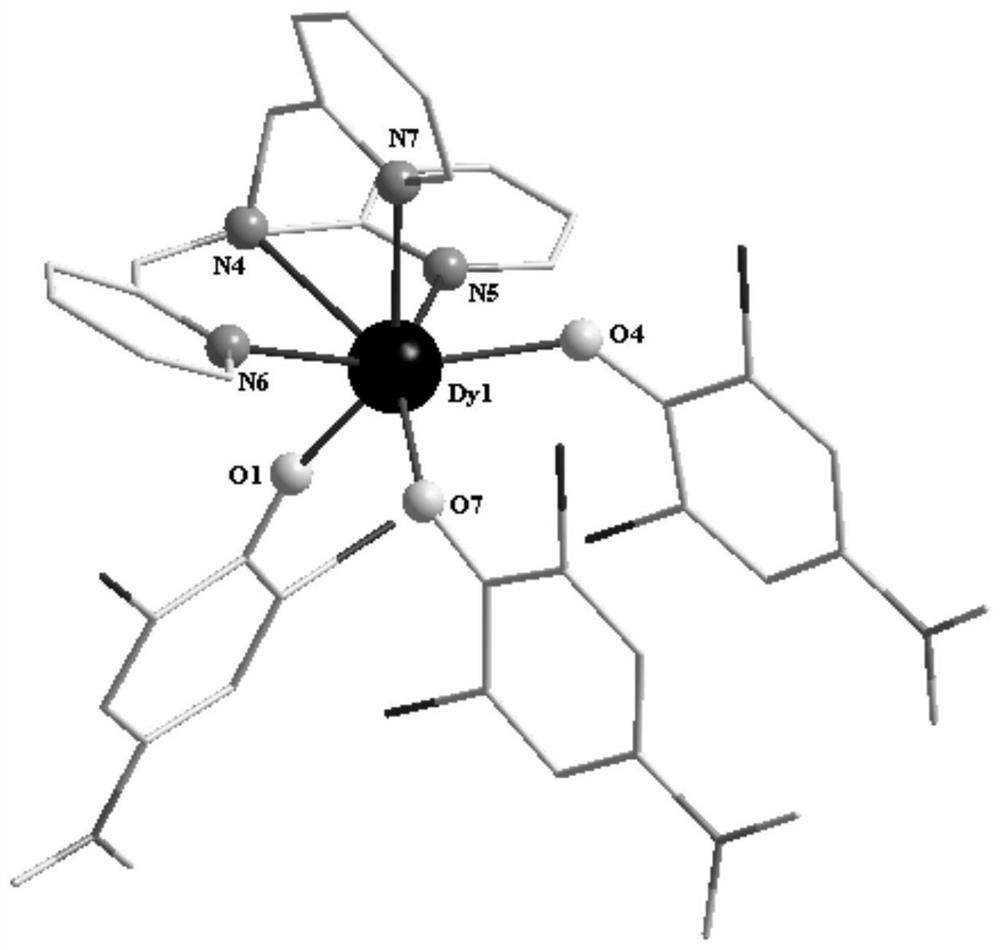

Mononuclear dysprosium magnetic complex as well as preparation method and application thereof

A complex, mononuclear technology, applied in the fields of organic chemistry methods, chemical instruments and methods, and magnetism of organic materials/organic magnetic materials, etc. High purity and yield, high controllability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The synthetic method of mononuclear dysprosium magnetic complex comprises the following steps:

[0028] Step 1, DyCl 3 ·6H 2 O (0.2mmol) and organic ligand TPA (0.2mmol) were stirred and mixed in 4mL of anhydrous methanol solution, and allowed to react for 10min;

[0029] Step two, HOPhCl 2 NO 2 (0.4mmol) was dissolved in 12mL of acetonitrile, triethylamine (0.8mmol) was added thereto, allowed to react for 5min, and then the mixed solution in step 1 was added to produce a yellow precipitate;

[0030] Step 3: Dissolve the yellow precipitate in step 2 in 4 mL of dichloromethane, transfer it to a test tube, slowly drop in 10 mL of n-hexane to form a two-phase layer, and let it stand for 2 days to obtain the crystal of the mononuclear dysprosium-based magnetic complex.

[0031] The yield of the mononuclear dysprosium magnetic complex prepared in this example was 57.8%.

Embodiment 2

[0033] The synthetic method of mononuclear dysprosium magnetic complex comprises the following steps:

[0034] Step 1, DyCl 3 ·6H 2 O (0.2mmol) and organic ligand TPA (0.2mmol) were stirred and mixed in 6mL absolute ethanol solution, and allowed to react for 10min;

[0035] Step two, HOPhCl 2 NO 2 (0.4mmol) was dissolved in 5mL acetonitrile, triethylamine (0.6mmol) was added thereto, allowed to react for 5min, and then the mixed solution in step 1 was added to produce a yellow precipitate;

[0036] Step 3. Dissolve the yellow precipitate in step 2 in 5 mL of dichloromethane, transfer it to a test tube, slowly drop in 15 mL of n-hexane to form two-phase separation, and obtain the crystal of the mononuclear dysprosium-based magnetic complex after 2 days.

[0037] The yield of the mononuclear dysprosium magnetic complex prepared in this example was 58.4%.

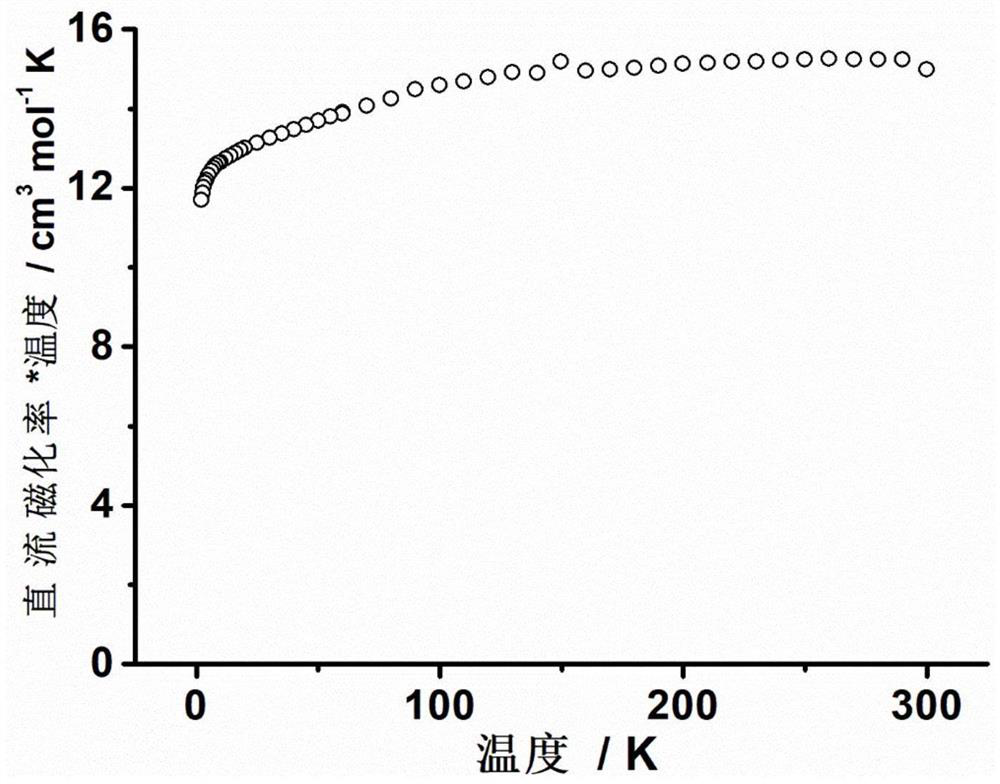

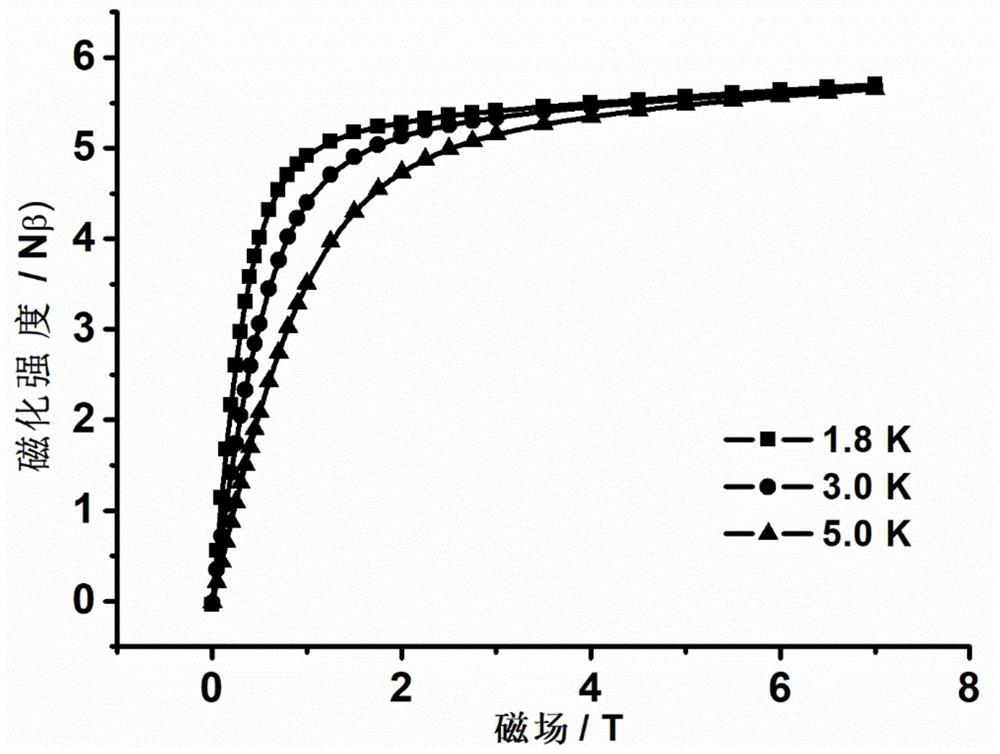

[0038] The characterization of the mononuclear dysprosium magnetic complex prepared in this example is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com