Preparation method of white carbon black coated yellow-green fluorescent nano-filler for rubber

A fluorescent nanometer and white carbon black technology is applied in the field of preparation of yellow-green fluorescent nanometer fillers coated with white carbon black for rubber, which can solve the problems of no fluorescence, limited application, etc. dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

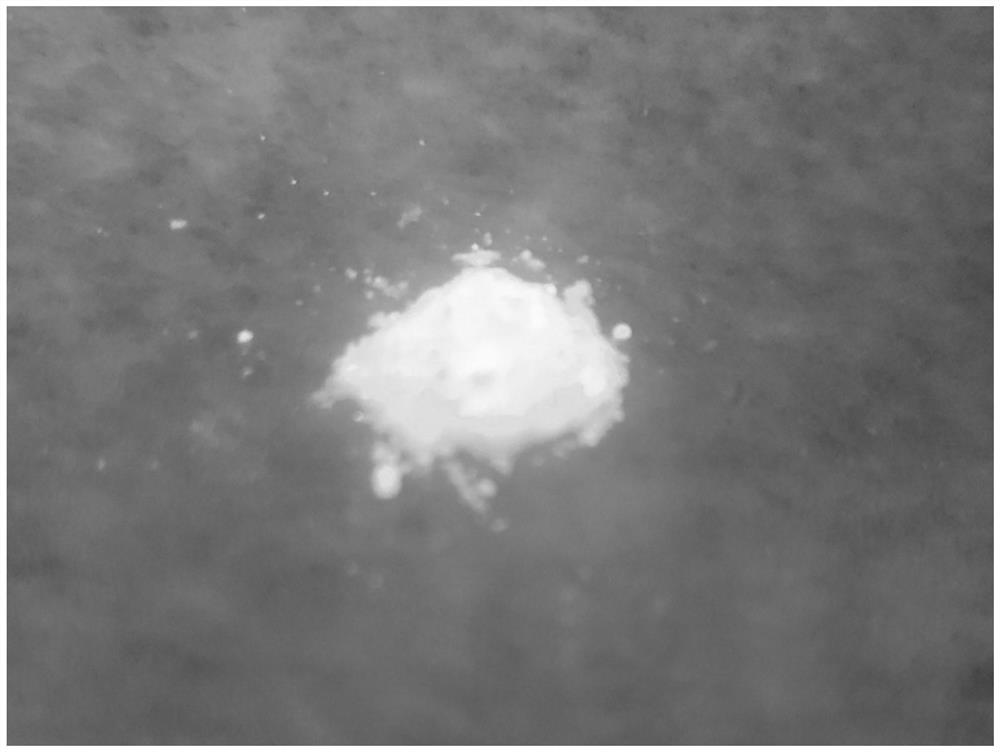

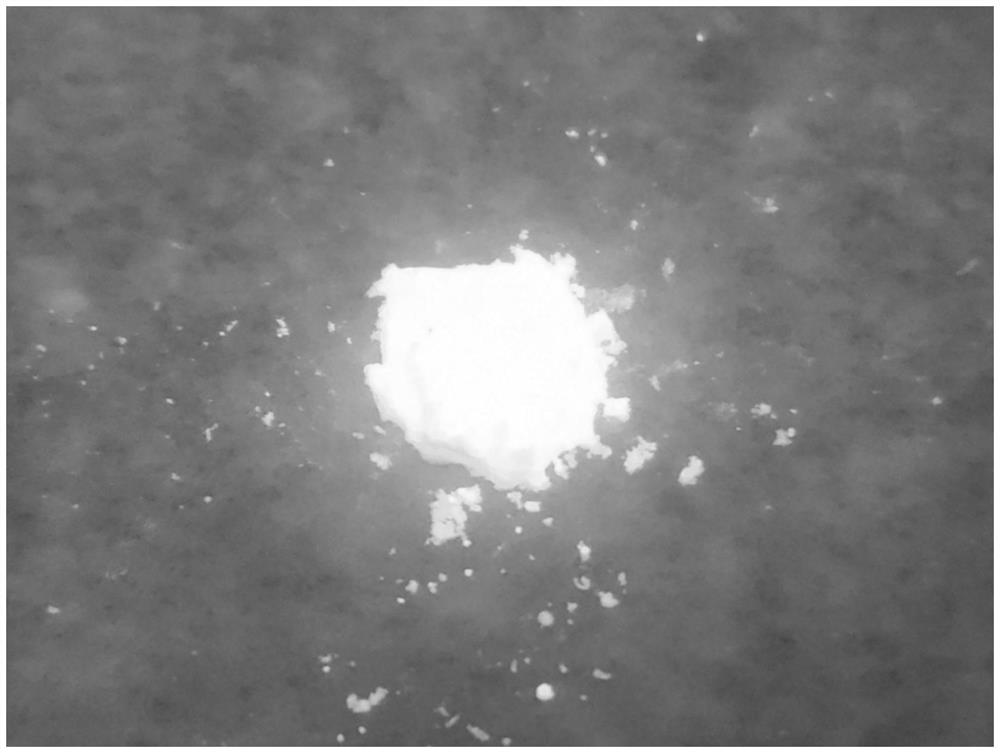

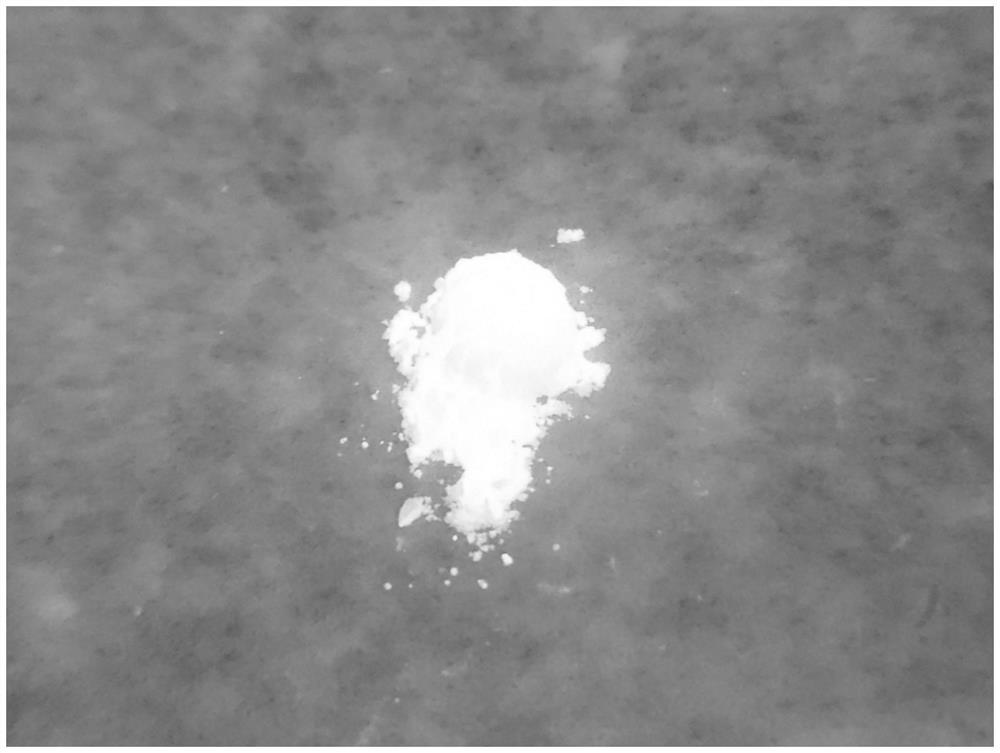

Image

Examples

Embodiment 1

[0028] A preparation method for coating white carbon black for rubber with yellow-green fluorescent nano-filler, the method steps comprising:

[0029] Step 1): Mix 9 mL of toluene with 0.102 g of polyol-type nonionic surfactant Span / Tween (the mass ratio of Span-80 and Tween-80 is 3:1), stir with a magnetic stirrer at 500 r / min 30min, so that the two form a uniform and stable oil phase.

[0030] Step 2): Take 310μL Fc respectively 16 AB aqueous solution and 155 μL FS aqueous solution, first add 465 μL of concentrated ammonia water to the FS aqueous solution, and then add Fc 16 AB aqueous solution, mix and stand for 1min to form an aqueous phase;

[0031] Step 3): Mix the oil phase of step 1) with the water phase of step 2) in a volume ratio of 1:1, and stir for 7 minutes at a rotating speed of 8000r / min to form a microemulsion;

[0032] Step 4): Add 3.8mL tetraethyl orthosilicate to the above microemulsion, and stir for 24 hours at a rotation speed of 300r / min to obtain a p...

Embodiment 2

[0036] A preparation method for coating white carbon black for rubber with yellow-green fluorescent nano-filler, the method steps comprising:

[0037] Step 1): Mix 9 mL of toluene with 0.047 g of polyol-type nonionic surfactant Span / Tween (the mass ratio between Span-80 and Tween-80 is 3:1), and stir with a magnetic stirrer at 500 r / min 40min, so that the two form a uniform and stable oil phase.

[0038] Step 2): Take 310μL Fc respectively 16 AB aqueous solution and 155 μL FS aqueous solution, first add 535 μL concentrated ammonia water to the FS aqueous solution, and then add Fc 16 AB aqueous solution, mix and stand for 2 minutes to form an aqueous phase;

[0039] Step 3): Mix the oil phase and the water phase at a volume ratio of 1:1, and stir for 6 minutes at a rotating speed of 9000r / min to form a microemulsion;

[0040] Step 4): Add 5mL tetraethyl orthosilicate into the above microemulsion, and stir for 20h at a rotation speed of 400r / min;

[0041] Step 5): drying the...

Embodiment 3

[0044] A preparation method for coating white carbon black for rubber with yellow-green fluorescent nano-filler, the method steps comprising:

[0045] Step 1): Mix 9 mL of toluene with 0.204 g of polyol-type nonionic surfactant Span / Tween (the mass ratio between Span-80 and Tween-80 is 3:1), and stir at 500 r / min with a magnetic stirrer 45min to make the two form a uniform and stable oil phase.

[0046] Step 2): Take 310μL Fc respectively 16 AB aqueous solution and 155 μL FS aqueous solution, first add 765 μL of concentrated ammonia water to the FS aqueous solution, and then add Fc 16 AB aqueous solution, mix and stand for 3 minutes to form an aqueous phase;

[0047] Step 3): Mix the oil phase and the water phase at a volume ratio of 1:1, and stir for 5 minutes at a rotating speed of 10000r / min to form a microemulsion;

[0048] Step 4): Add 6 mL of tetraethyl orthosilicate to the above microemulsion, and stir for 16 h at a rotation speed of 500 r / min;

[0049] Step 5): dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com