Soft tissue filling hydrogel for medical cosmetology and preparation method of soft tissue filling hydrogel

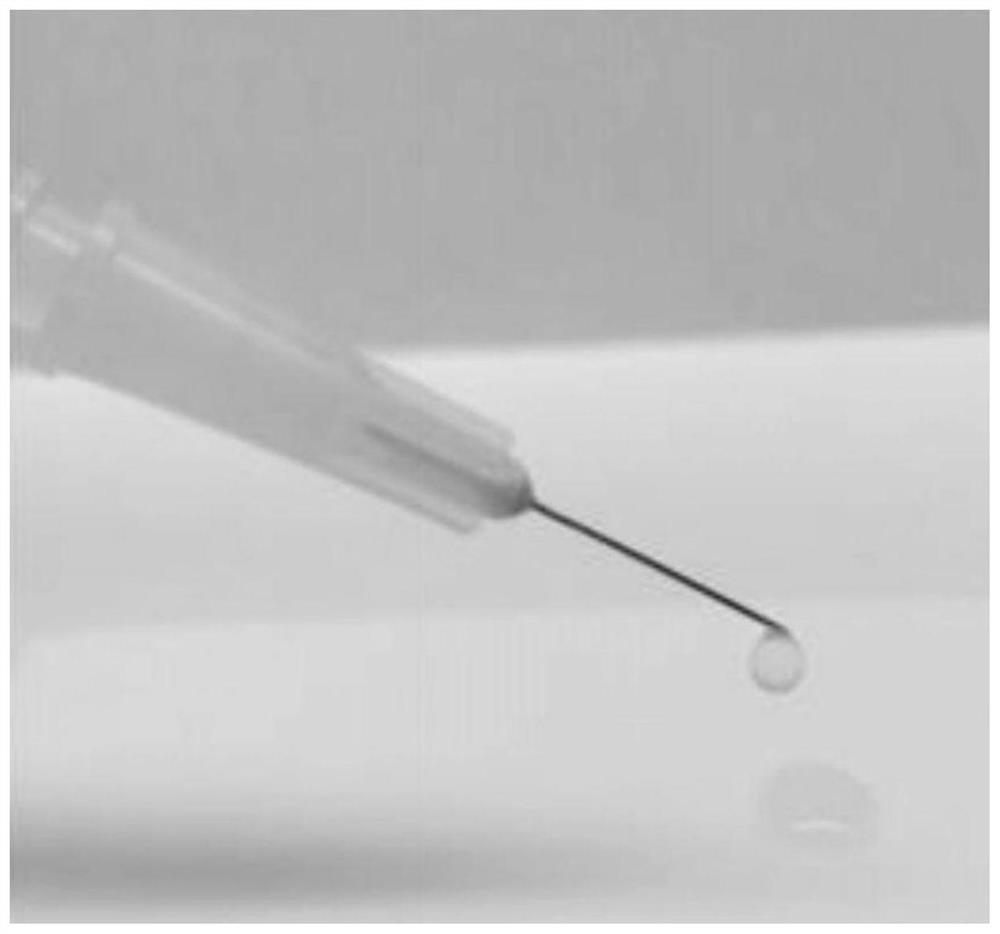

A hydrogel and soft tissue technology, which is applied in the field of medical cosmetology, can solve the problems of poor stability of soft tissue fillers and other problems, and achieve excellent filling effect, excellent needle penetration and filling effect, and improve needle penetration and filling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Figure 4 A schematic flowchart showing a method for preparing a soft tissue filling hydrogel according to an embodiment of the present invention. Such as Figure 4 Shown, this preparation method comprises:

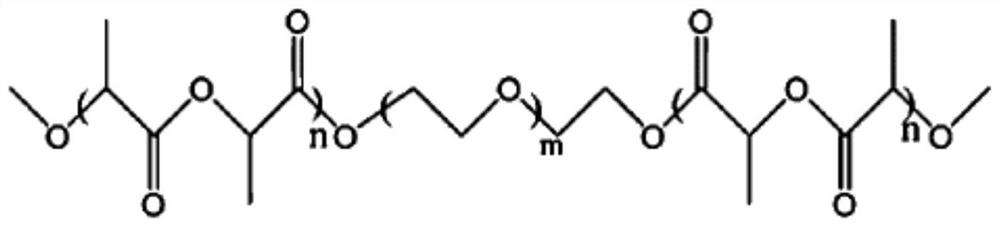

[0059] In step S100, polyethylene glycol is used as an initiator and lactide is used as a monomer to obtain a poly-L-lactic acid-polyethylene glycol-poly-L-lactic acid copolymer precursor or a poly-l-lactic acid-poly Ethylene glycol-poly lactic acid copolymer precursor;

[0060] Step S200, purifying the poly-L-lactic acid-polyethylene glycol-poly-L-lactic acid copolymer precursor or the poly-l-lactic acid-polyethylene glycol-poly-l-lactic acid copolymer precursor by solvent-anti-solvent precipitation method to obtain Poly-L-lactic acid-polyethylene glycol-poly-L-lactic acid copolymer or poly-l-lactic acid-polyethylene glycol-poly-l-lactic acid copolymer;

[0061] Step S300, reconstitute the poly-L-lactic acid-polyethylene glycol-poly-L-lactic acid copolymer or ...

Embodiment 1

[0073] The embodiment of the present invention provides a method for preparing a soft tissue filling hydrogel, comprising the following steps:

[0074] 1) Weigh 100g of L-lactide and 300g of polyethylene glycol (10000Da) (polymerization ratio: 1:3) into a round bottom flask, heat to 110°C and stir until the two raw materials are completely melted and mixed evenly;

[0075] 2) Under stirring conditions, add 0.4 g of stannous octoate catalyst, and raise the reaction temperature to 130 ° C to initiate ring-opening polymerization of L-lactide for 18 hours to obtain a PLLA-PEG-PLLA copolymer precursor;

[0076] 3) Dissolve the PLLA-PEG-PLLA copolymer precursor with 2L of dichloromethane, then settle with 10L of n-hexane, repeat 5 times, and vacuum dry to obtain a purified PLLA-PEG-PLLA copolymer;

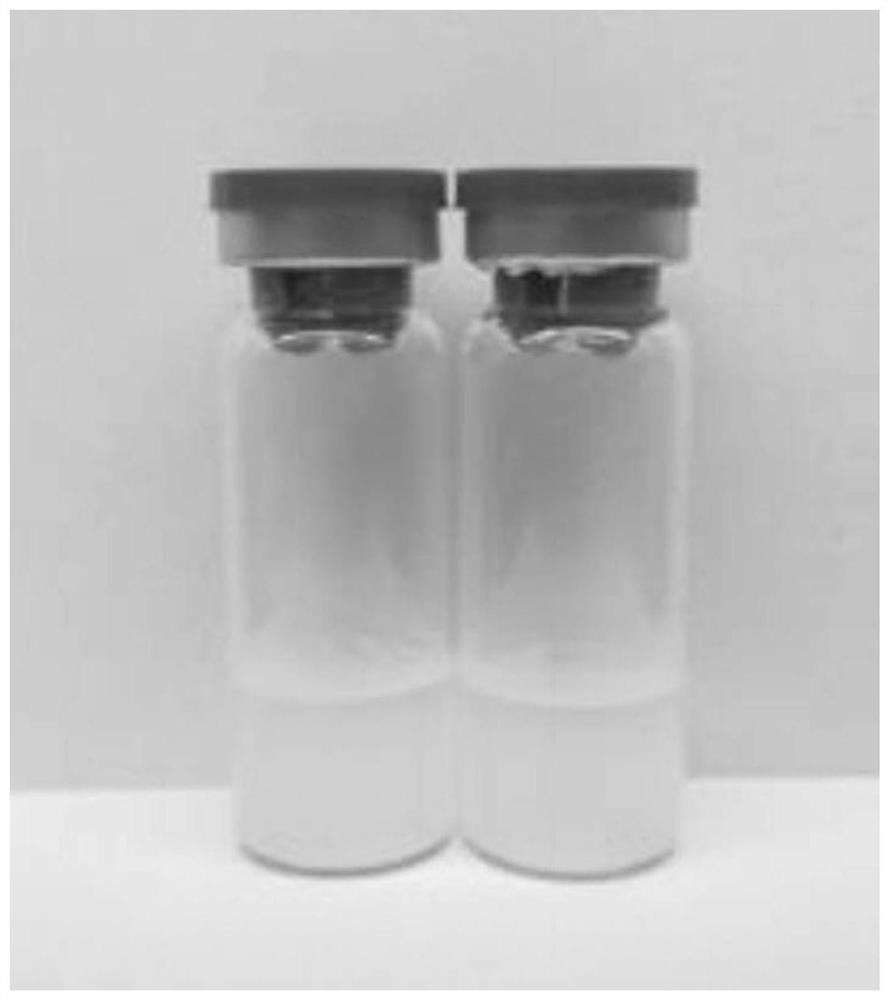

[0077] 4) Weigh 250g of PLLA-PEG-PLLA copolymer, 15g of sodium carboxymethylcellulose, 25g of mannitol and 10g of tranexamic acid and add them to 2.5 liters of normal saline for injectio...

Embodiment 2

[0080] The embodiment of the present invention provides a method for preparing a soft tissue filling hydrogel, comprising the following steps:

[0081]1) Weigh 80g of L-lactide and 320g of polyethylene glycol (10000Da) (polymerization ratio: 1:4) into a round bottom flask, heat to 110°C and stir until the two raw materials are completely melted and mixed evenly;

[0082] 2) Under stirring conditions, add 0.4 g of stannous octoate catalyst, and raise the reaction temperature to 130 ° C to initiate ring-opening polymerization of L-lactide for 12 hours to obtain a PLLA-PEG-PLLA copolymer precursor;

[0083] 3) Dissolve the PLLA-PEG-PLLA copolymer precursor with 2L of dichloromethane, then settle with 10L of n-hexane, repeat 5 times, and vacuum dry to obtain a purified PLLA-PEG-PLLA copolymer;

[0084] 4) Weigh 250g of PLLA-PEG-PLLA copolymer, 15g of sodium hyaluronate, 25g of mannitol and 10g of tranexamic acid into 2.5 liters of normal saline for injection and stir magnetically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com