Anhydride modified passion fruit peel bio-adsorbent and preparation method and application thereof

A technology of biosorbent and passion fruit peel, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problems of slow adsorption rate, low adsorption capacity, and restricted application, and achieve low cost and high The effect of adsorption capacity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

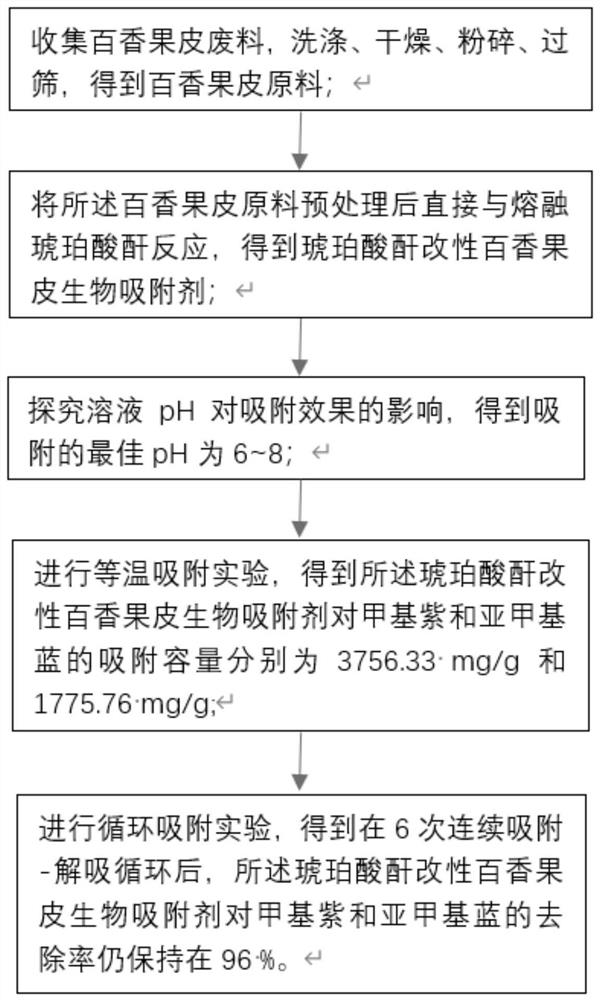

[0036] The invention provides a kind of preparation method of acid anhydride modified passion fruit peel biosorbent, comprising the following steps:

[0037] Dispersing the passion fruit peel raw material in the first NaOH solution for the first treatment to obtain the first NaOH treatment product;

[0038] Dispersing the first NaOH-treated product in a second NaOH solution, then adding hydrogen peroxide dropwise for bleaching, then sequentially performing solid-liquid separation, washing with water to neutrality, and freeze-drying to obtain a pretreated material;

[0039] The pretreatment material is mixed with an acid anhydride for esterification reaction, and the resulting esterification product is dispersed in a saturated sodium bicarbonate solution to obtain the acid anhydride-modified passion fruit peel biosorbent, and the acid anhydride is succinic anhydride or maleic anhydride .

[0040] In the present invention, the passion fruit peel raw material is dispersed in the...

Embodiment 1

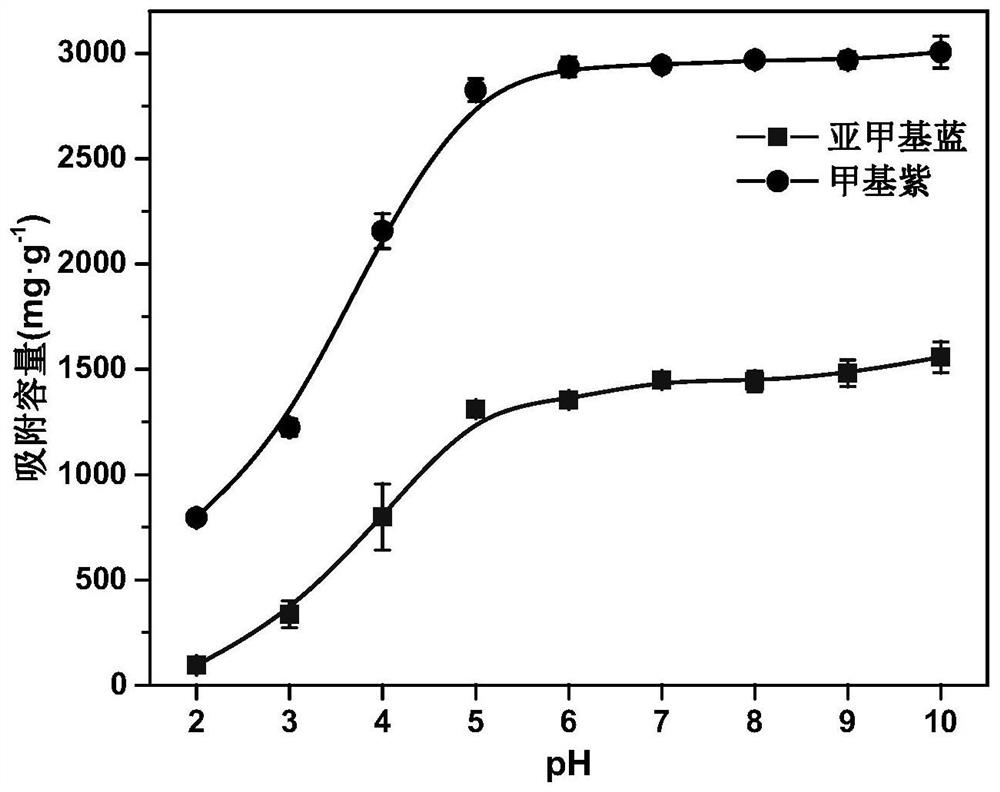

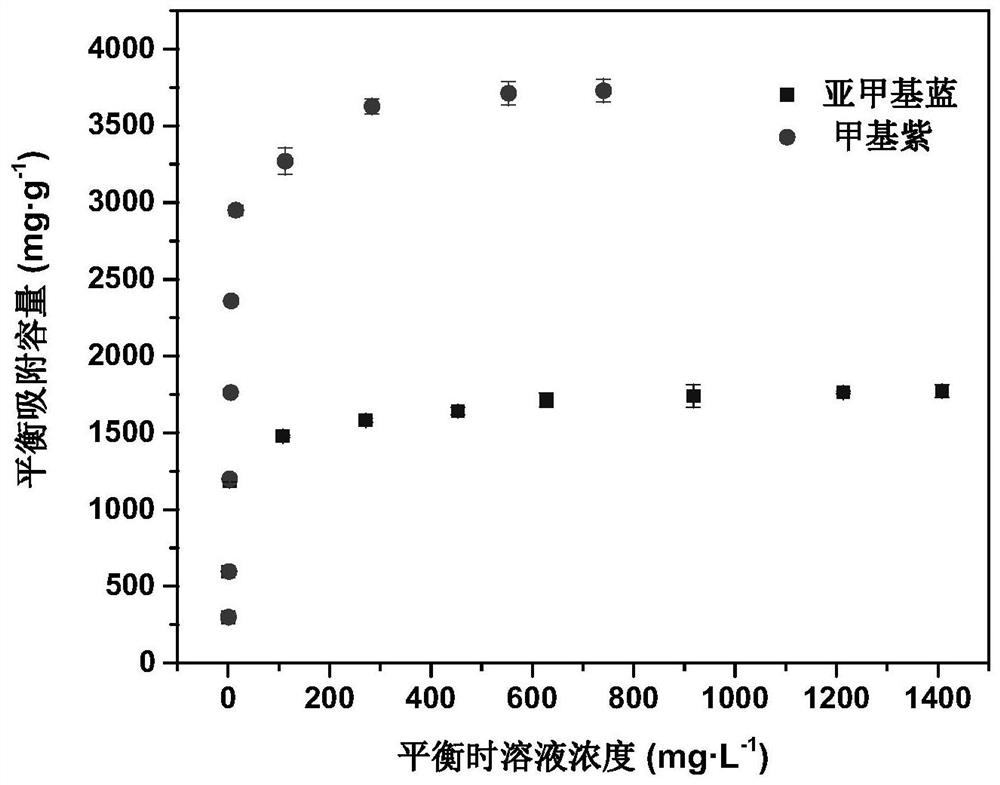

[0066] figure 1 The preparation and application flowchart of a kind of succinic anhydride modified passion fruit peel biosorbent provided in Example 1.

[0067] The preparation method of succinic anhydride modified passion fruit peel biosorbent, concrete steps are as follows:

[0068] (1) Collect passion fruit peel waste from passion fruit orchards, fully wash, cut into pieces, dry, crush, and pass through a 60-100 mesh sieve to obtain passion fruit peel raw materials;

[0069] (2) Disperse 20 g of passion fruit peel raw material in 400 mL of 2 mol / L NaOH solution, stir at 80 °C for 4 h, filter and wash with suction. Disperse the product in 400 mL of NaOH solution with a concentration of 1 mol / L, heat to 50 °C, add 200 mL of hydrogen peroxide dropwise, continue stirring for 60 min, filter with suction, wash with deionized water until neutral, and freeze-dry , crushed to obtain the pretreated material.

[0070] (3) Add 2 g of pretreated material to 20 g of molten succinic an...

Embodiment 2

[0079] Figure 6 The preparation and application flowchart of a kind of maleic anhydride modified passion fruit peel biosorbent provided in Example 2.

[0080] The preparation method of maleic anhydride modified passion fruit peel biosorbent, concrete steps are as follows:

[0081] (1) Collect the passion fruit peel waste from the food factory, fully wash, cut into pieces, dry, crush, and pass through a 60-100 mesh sieve to obtain the passion fruit peel raw material;

[0082] (2) Disperse 20 g of passion fruit peel raw material in 400 mL of 2 mol / L NaOH solution, stir at 80 °C for 4 h, filter and wash with suction. Disperse the product in 400 mL of NaOH solution with a concentration of 1 mol / L, heat to 50 °C, add 200 mL of hydrogen peroxide dropwise, continue stirring for 60 min, filter with suction, wash with deionized water until neutral, and freeze-dry , crushed to obtain the pretreated material.

[0083] (3) Add 2 g of pretreatment materials and 20 g of maleic anhydride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com