Aqueous lithium ion electrolyte and battery

A lithium ion and electrolyte technology, applied in the field of secondary batteries, can solve the problems of high electrolyte viscosity, large amount of lithium salt, high cost, etc., and achieve the effects of low viscosity, high ion conductivity, and high Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

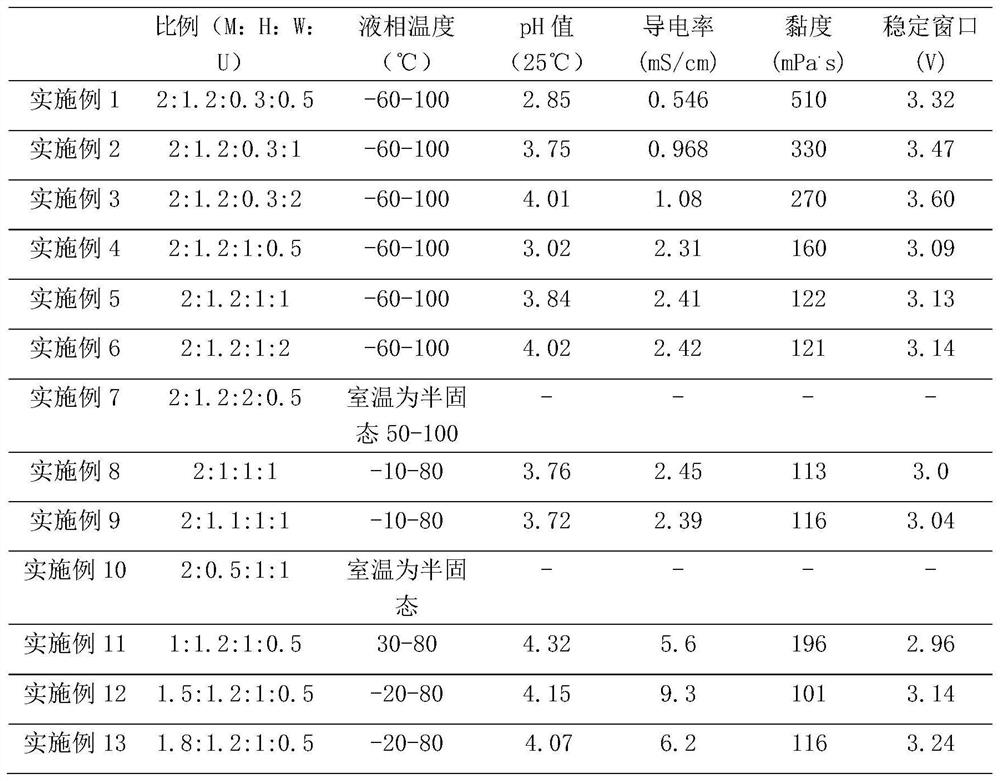

[0023] Dimethyl sulfone (M), lithium perchlorate (L), pure water (H), and urea (U) were used as raw materials, mixed according to a certain ratio and ground, and the mixture was placed in a water bath at 50°C until ultrasonic Obtain a transparent homogeneous solution, and test the electrochemical stability window, conductivity, viscosity, pH value, liquidus temperature, etc. of the obtained solution.

[0024] The various test parameters of embodiment 1-13 gained solution are as figure 1 shown.

Embodiment 14-20

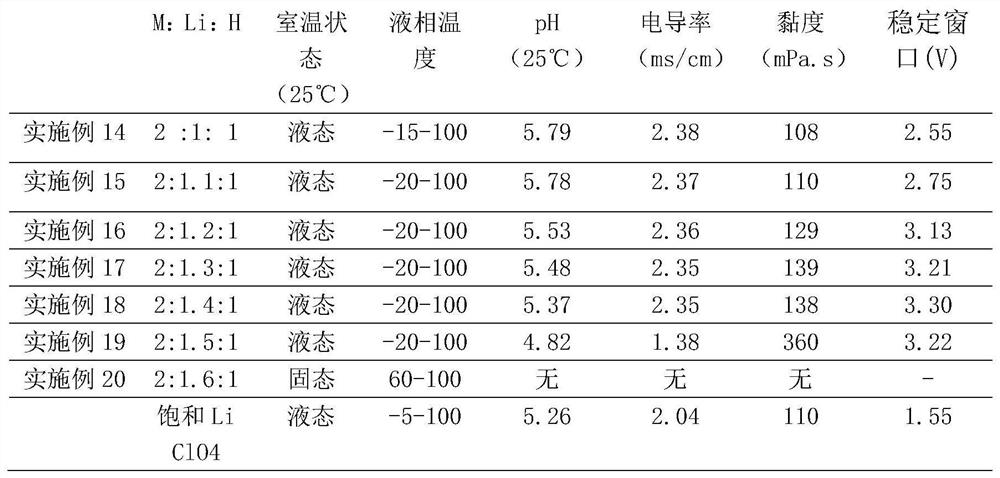

[0026] Dimethyl sulfone (M), lithium perchlorate (L) and pure water (H) are used as raw materials, mixed according to a certain ratio and then ground, and the mixture is placed in a water bath at 50°C until a transparent homogeneous phase is obtained. solution, and test the electrochemical stability window, conductivity, viscosity, pH value, liquidus temperature, etc. of the obtained solution.

[0027] The various test parameters of embodiment 14-20 gained solution are as figure 1 shown.

Embodiment 21

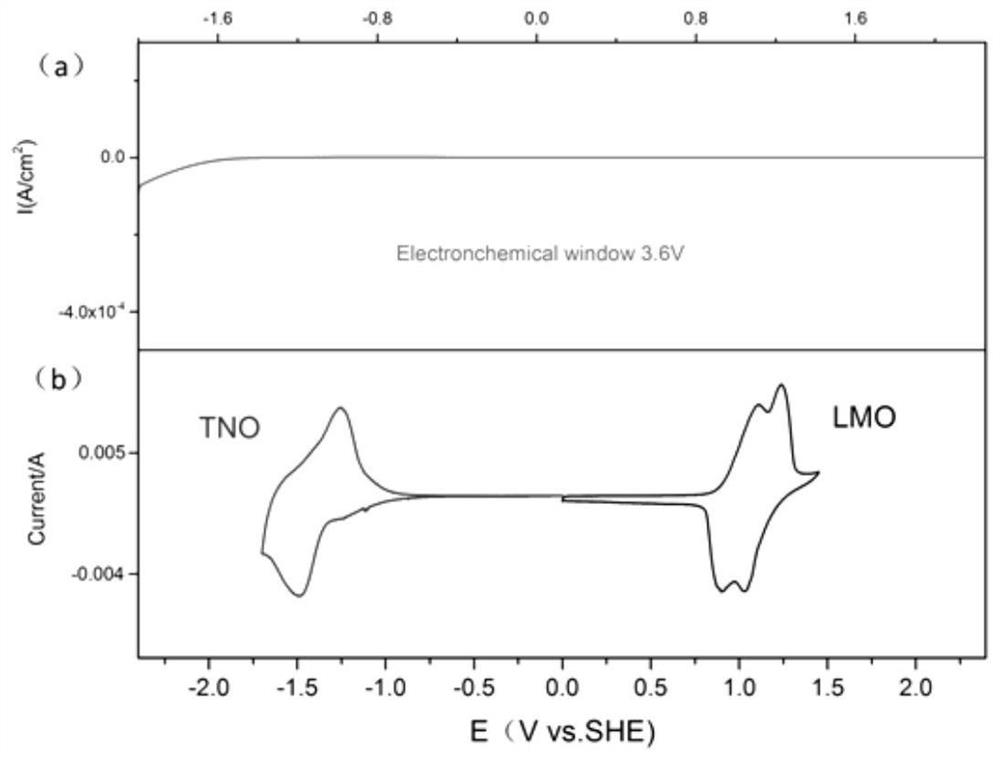

[0029] With the solution prepared in embodiment 2 as electrolyte, lithium manganate (LiMn 2 o 4 ) and titanium niobate (TiNb 2 o 7 ) are the positive and negative active materials of aqueous lithium-ion batteries, respectively. According to the active material:conductive agent:binder mass ratio of 8:1:1, the corresponding amount was weighed, and an appropriate amount of N-methylpyrrolidone (NMP) was added to grind it into a battery slurry. The method of manual mixing and coating, the hand-ground battery slurry positive electrode is uniformly coated on the titanium foil with a coating film applicator (200 μm), and the negative electrode is evenly coated on the aluminum foil with a coating film applicator (100 μm) superior. Then transfer the coated positive and negative electrodes to an oven at 100°C and 90°C for 10 hours, and use a pole piece punch to make the dried positive and negative electrodes into circular pole pieces with a diameter of 16mm, among which the positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com