Preparation method of silicon carbide coating graphite base

A silicon carbide coating and graphite base technology, applied in the field of semiconductors, can solve the problems affecting the use of the graphite base and the performance of the coating, and achieve the effects of high compactness, improved thermal shock resistance and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

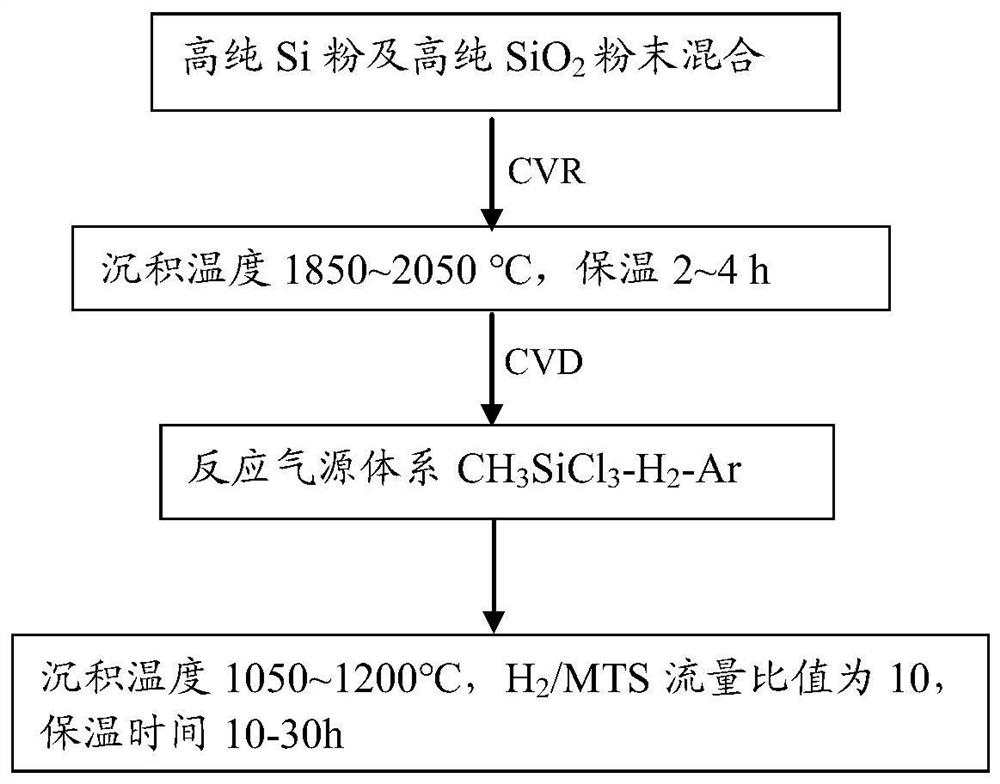

[0030] Such as figure 1 As shown, this embodiment provides a method for preparing a silicon carbide-coated graphite base, which specifically includes the following steps:

[0031] S1. Graphite base pretreatment: Polish the graphite base, then place it in alcohol, clean it with ultrasonic waves for 20-40 minutes, and finally put it in an oven and dry it at 100°C for 30 minutes; after the pretreatment, the graphite The base is placed above the graphite gas distribution plate in the vacuum furnace;

[0032] S2, CVR deposition: Si powder and SiO 2 The powder is mixed in a molar ratio of 1:1, placed at the bottom of the graphite crucible, and then the graphite crucible is placed in a vacuum furnace to prevent SiO 2 The powder remains, and the mass of Si powder is 6% more; the vacuum furnace is vacuumed and argon is introduced, and the temperature is raised to 1850°C at a rate of 10-15°C / min in the argon atmosphere, and then the micro positive pressure Under the heat preservation...

Embodiment 2

[0039] Such as figure 1 As shown, this embodiment provides a method for preparing a silicon carbide-coated graphite base, which specifically includes the following steps:

[0040] S1. Graphite base pretreatment: Polish the graphite base, then place it in alcohol, clean it with ultrasonic waves for 20-40 minutes, and finally put it in an oven and dry it at 100°C for 30 minutes; after the pretreatment, the graphite The base is placed above the graphite gas distribution plate in the vacuum furnace;

[0041] S2, CVR deposition: Si powder and SiO 2 The powder is mixed in a molar ratio of 1:1, placed at the bottom of the graphite crucible, and then the graphite crucible is placed in a vacuum furnace to prevent SiO 2 The powder remains, and the mass of Si powder is 5% more; after vacuumizing the vacuum furnace, argon gas is introduced, and the temperature is raised to 1950 °C at a rate of 10-15 °C / min in the argon atmosphere, and then the micro positive pressure Under the heat pre...

Embodiment 3

[0044] Such as figure 1 As shown, this embodiment provides a method for preparing a silicon carbide-coated graphite base, which specifically includes the following steps:

[0045] S1. Graphite base pretreatment: Polish the graphite base, then place it in alcohol, clean it with ultrasonic waves for 20-40 minutes, and finally put it in an oven and dry it at 100°C for 30 minutes; after the pretreatment, the graphite The base is placed above the graphite gas distribution plate in the vacuum furnace;

[0046] S2, CVR deposition: Si powder and SiO 2 The powder is mixed in a molar ratio of 1:1, placed at the bottom of the graphite crucible, and then the graphite crucible is placed in a vacuum furnace to prevent SiO 2 The powder remains, and the quality of Si powder is 10% more; the vacuum furnace is vacuumed and argon is introduced, and the temperature is raised to 2050 °C at a rate of 10-15 °C / min in the argon atmosphere, and then the micro positive pressure Under the heat preser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com