A kind of high physical properties solvent-free polyurethane fabric resin for leather and preparation method thereof

A solvent-free polyurethane technology with high physical properties, applied in the field of leather, can solve the problem of not achieving complete environmental protection, and achieve the effects of high physical properties, enhancing resin physical properties, and adjusting resin viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

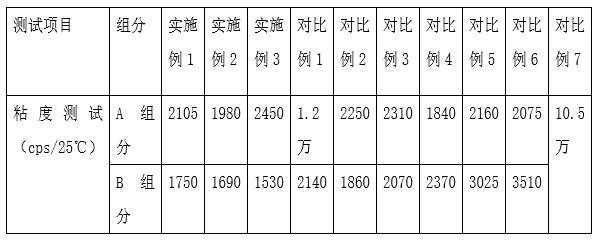

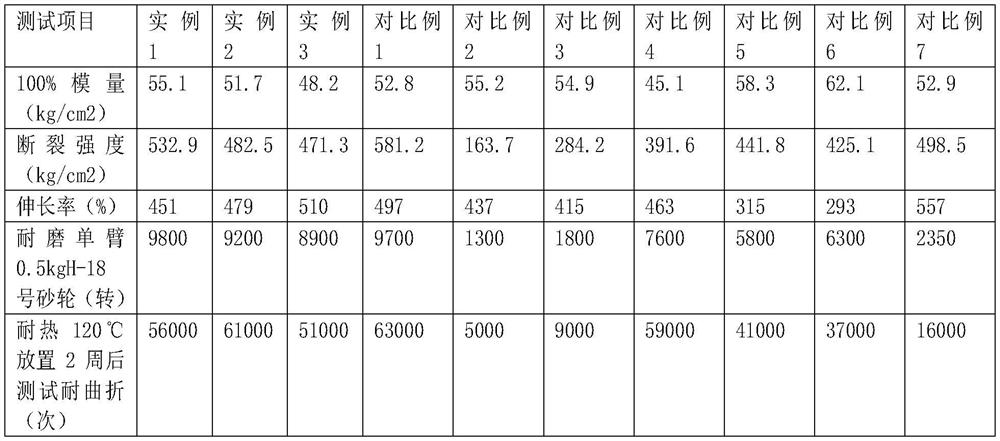

Examples

Embodiment 1

[0029] The preparation method of a kind of high physical properties solvent-free polyurethane fabric resin for leather described in this embodiment comprises the following steps:

[0030] (1) Preparation of component A: Put 300 parts of polycaprolactone polycarbonate copolymer polyol (number average molecular weight 1800g / mol, viscosity 2700cps / 25°C) into the reaction kettle, stir and heat up to 110°C, Vacuumize and dehydrate for 2 hours under the condition of vacuum degree -0.09MPa, then cool down to 70°C, add 10 parts of 4,4-diphenylmethane diisocyanate, 2.5 parts of MDI-50 (50% 4,4-diphenylmethane diisocyanate isocyanate, a mixture of 50% 2,4-diphenylmethane diisocyanate), reacted for 3 hours until the NCO content was <0.2%, lowered the temperature to 40°C, and added 9.4 parts of polyfunctional polycaprolactone polyol (number average molecular weight 1000 g / mol, functionality 3), 3.1 parts of ethylene glycol, 9.4 parts of dipropylene glycol, 15.6 parts of bisphenol F epoxy ...

Embodiment 2

[0034] The preparation method of a kind of high physical properties solvent-free polyurethane fabric resin for leather described in this embodiment comprises the following steps:

[0035] (1) Preparation of component A: Put 200 parts of polycaprolactone polycarbonate copolymer polyol (number average molecular weight 2000g / mol, viscosity 4600cps / 25℃) into the reaction kettle, stir and heat up to 130℃, Vacuumize and dehydrate for 3 hours under the condition of vacuum degree -0.01MPa, then cool down to 90°C, add 5.2 parts of toluene diisocyanate, react for 5 hours, until the NCO content is <0.2%, cool down to 60°C, add 6.2 parts of polyfunctional polyethylene Lactone polyol (number average molecular weight 1200 g / mol, functionality 3.5), 4.1 parts of 2-methyl-1,3-propanediol, 8.2 parts of diethylene glycol, 12.3 parts of bisphenol A epoxy resin (Epoxy equivalent 178 g / eq, viscosity 6000cps / 25°C), 0.4 parts polysiloxane defoamer, 0.5 parts polysiloxane leveling agent, 0.7 parts or...

Embodiment 3

[0039] The preparation method of a kind of high physical properties solvent-free polyurethane fabric resin for leather described in this embodiment comprises the following steps:

[0040] (1) Preparation of component A: Put 160 parts of polycaprolactone polycarbonate copolymer polyol (number average molecular weight 1500g / mol, viscosity 2100cps / 25°C) into the reactor, stir and heat up to 120°C, Vacuumize and dehydrate for 3 hours under the condition of vacuum degree -0.095MPa, then cool down to 80°C, add 5.6 parts of dicyclohexylmethane diisocyanate and 3.6 parts of 1,6-hexamethylene diisocyanate, react for 4 hours until the NCO content is <0.2%, and cool down To 50°C, add 8.5 parts of multifunctional polycaprolactone polyol (number-average molecular weight 1600 g / mol, functionality 3.2), 1.7 parts of 1,3-propanediol, 3.4 parts of 3-methyl-1.5 pentanediol , 11.8 parts of bisphenol F epoxy resin (epoxy equivalent 183g / eq, viscosity 12000cps / 25°C), 0.3 parts of polysiloxane defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com