Method for recovering nickel from electroplating waste liquid by using diphosphonic acid extracting agent

A technology for electroplating waste liquid and extraction agent, applied in the field of hydrometallurgy, can solve the problems of increasing the amount of treatment after extraction, the inability of nickel reserves to meet the demand, the consumption of large alkaline reagents, etc. The effect of volatilization and reduction of organic phase loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) to contain Ni 2+ The electroplating waste solution is the water phase, and the Ni in the water phase 2+ The concentration is 0.7 g / L, and the pH of the aqueous phase is 4.

[0026] (2) Prepare 0.025mol / L HADMPPA and OADMPPA as the organic phase with diluent, dichloromethane, toluene, dichloroethane and chloroform respectively.

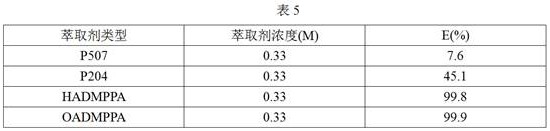

[0027] (3) Mix 5 mL each of the aqueous phase and the organic phase, extract for 10 min, and extract at 25 °C, and measure Ni in the raffinate 2+ See Table 1 for the concentration of the diluent on the extraction rate.

[0028] (4) Use 0.1mol / L dilute hydrochloric acid to carry out organic back-extraction after extraction. The back-extraction time is 20 minutes, the back-extraction temperature is 20°C, and the back-extraction rate is above 99%.

[0029]

Embodiment 2

[0031] (1) to contain Ni 2+ The electroplating waste solution is the water phase, and the Ni in the water phase 2+ The concentration of the solution is 0.8 g / L, and the pH of the aqueous phase is 1.

[0032] (2) Using chloroform as the diluent, prepare 0.0565 mol / L HADMPPA as the organic phase.

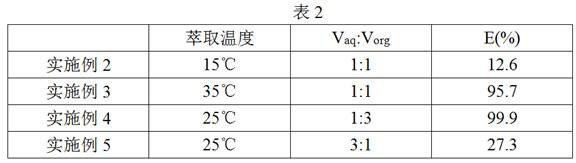

[0033] (3) 10 mL of the aqueous phase and organic phase were mixed, the extraction time was 10 min, the extraction temperature was 15 °C, and the Ni in the raffinate was determined 2+ The concentration and extraction rate are shown in Table 2.

[0034] (4) Use 0.1mol / L dilute hydrochloric acid to reverse the organic extraction after extraction. The stripping time is 30 min, the stripping temperature is 30°C, and the stripping rate is over 99%.

Embodiment 3

[0036] (1) to contain Ni 2+ The electroplating waste solution is the water phase, and the Ni in the water phase 2+ The concentration of the solution is 0.8 g / L, and the pH of the aqueous phase is 1.

[0037] (2) Using chloroform as the diluent, prepare 0.0565 mol / L HADMPPA as the organic phase.

[0038] (3) 10 mL of the aqueous phase and organic phase were mixed, the extraction time was 10 min, the extraction temperature was 35 °C, and the Ni in the raffinate was determined 2+ The concentration and extraction rate are shown in Table 2.

[0039] (4) Use 0.1mol / L dilute hydrochloric acid to reverse the organic extraction after extraction. The stripping time is 30 min, the stripping temperature is 30°C, and the stripping rate is over 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com