Preparation method of lithium-sulfur battery positive electrode aqueous conductive binder

A conductive binder and lithium-sulfur battery technology, which is applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low adhesion and low conductivity of sulfur positive electrodes, and achieve simple equipment and high output High efficiency and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Dissolve 5.04g of carboxymethylcellulose in 1675ml of deionized water and stir in a water bath at 60°C to form a solution;

[0044] (2) Dissolve 7 g of multi-walled carbon nanotube powder in 140 g of the solution prepared in step 1 by emulsifying and shearing for 60 min, and ultrasonically disperse for 20 min with a cell disruptor;

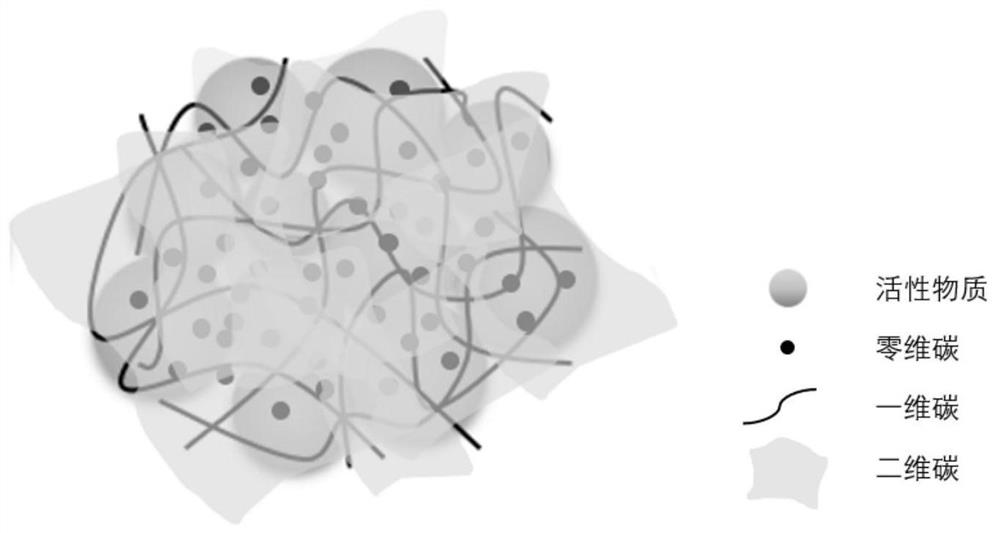

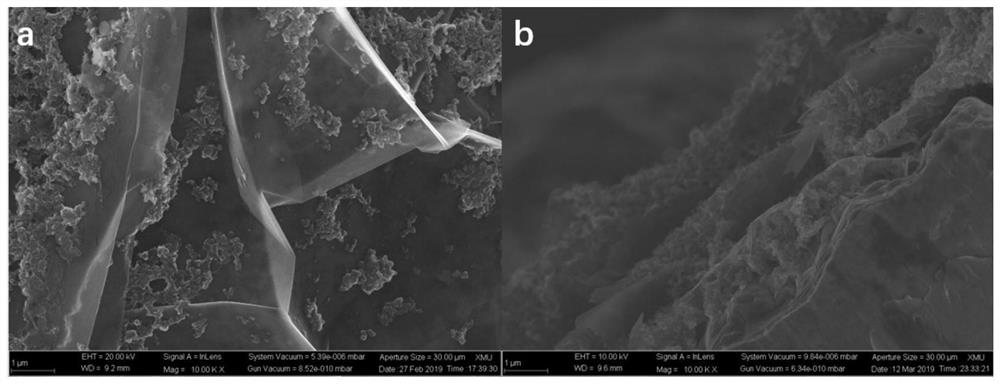

[0045] (3) In the air, 45g acetylene black and 15g expanded graphite and 400g solid content are 15% LA133 aqueous binding agent (acrylonitrile multiple copolymer) to pack in the feed tank, then pour into 1540g step 1 prepared The solution was used as a solvent, mechanically sanded at 750rpm for 1h, figure 2 Shown is the scanning electron micrograph of the prepared graphene conductive paste;

[0046](4) Take 400 g of the slurry obtained in step 3, add the carbon nanotube dispersion obtained in step 2 and 1 g of vapor-phase grown carbon fiber, and perform mechanical stirring treatment at 800 rpm for 2 h. Finally, 53 g of LA133 water-ba...

Embodiment 2

[0049] (1) Dissolve 0.216g of carboxymethylcellulose in 72ml of deionized water and stir in a water bath at 60°C to form a solution;

[0050] (2) Dissolve 1.75 g of multi-walled carbon tube powder in 35 g of the solution prepared in step 1 by mechanical stirring for 4 h, and ultrasonically disperse for 20 min with a cell disruptor;

[0051] (3) in the air, 2.25g acetylene black and 0.75g expanded graphite and 20g solid content are 15% LA133 water-based binding agent to pack in the ball mill jar, then pour into the prepared solution of 37g step 1 as solvent, in Mechanical ball milling under 350rpm rotating speed 4h; Wherein the used zirconia ball milling bead small bead (diameter is 3mm) and big bead (diameter is 8mm) are mixed according to the mass ratio of 1:5;

[0052] (4) Add the carbon nanotube dispersion obtained in step 2 and 0.25 g of vapor-phase grown carbon fibers to the slurry obtained in step 3, and perform mechanical stirring treatment at 800 rpm for 2 h. Finally,...

Embodiment 3

[0056] (1) Dissolve 0.156g of carboxymethylcellulose in 52ml of deionized water and stir in a water bath at 60°C to form a solution;

[0057] (2) Dissolve 0.75 g of multi-walled carbon tube powder in 15 g of the solution prepared in step 1 by mechanical stirring for 4 h, and ultrasonically disperse for 20 min with a cell disruptor;

[0058] (3) in the air, 2.25g acetylene black and 0.75g expanded graphite and 20g solid content are 15% LA133 water-based binding agent to pack in the ball mill jar, then pour into the prepared solution of 37g step 1 as solvent, in Mechanical ball milling at 350rpm for 4 hours;

[0059] (4) Add the carbon nanotube dispersion obtained in step 2 to the slurry obtained in step 3, and perform mechanical stirring treatment at 800 rpm for 2 hours. Finally, 5 g of LA133 water-based binder with a solid content of 15% was added and mechanically stirred at 1000 rpm for 6 hours to prepare a water-based composite conductive binder. The carbon material mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com