Quantum dot-modified multi-shell CaTiO3 cube, and preparation method and application thereof

A technology of quantum dots and cubes, applied in the field of quantum dot-modified multi-shell CaTiO3 cubes and their preparation, can solve the problem of poor photocatalyst active sites and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step: Ni 2 Preparation of P quantum dots

[0030] First, 0.5mol Ni(NO 3 ) 2 ·6H 2 O was dispersed in deionized water, slowly added to 0.15M NaOH solution under magnetic stirring, and then dried in an oil bath at 80 °C. Add a certain amount of NaH 2 PO 2 Grind for 30 min in an agate mortar. Next, the mixture was placed in a porcelain boat wrapped in tinfoil and heated in a tube furnace at 400 °C for 4 h at 2 °C / min, N 2 . It is worth noting that the molar ratio of Ni:OH:P is 1:10:10. Finally, the Ni 2 P quantum dots.

Embodiment 2

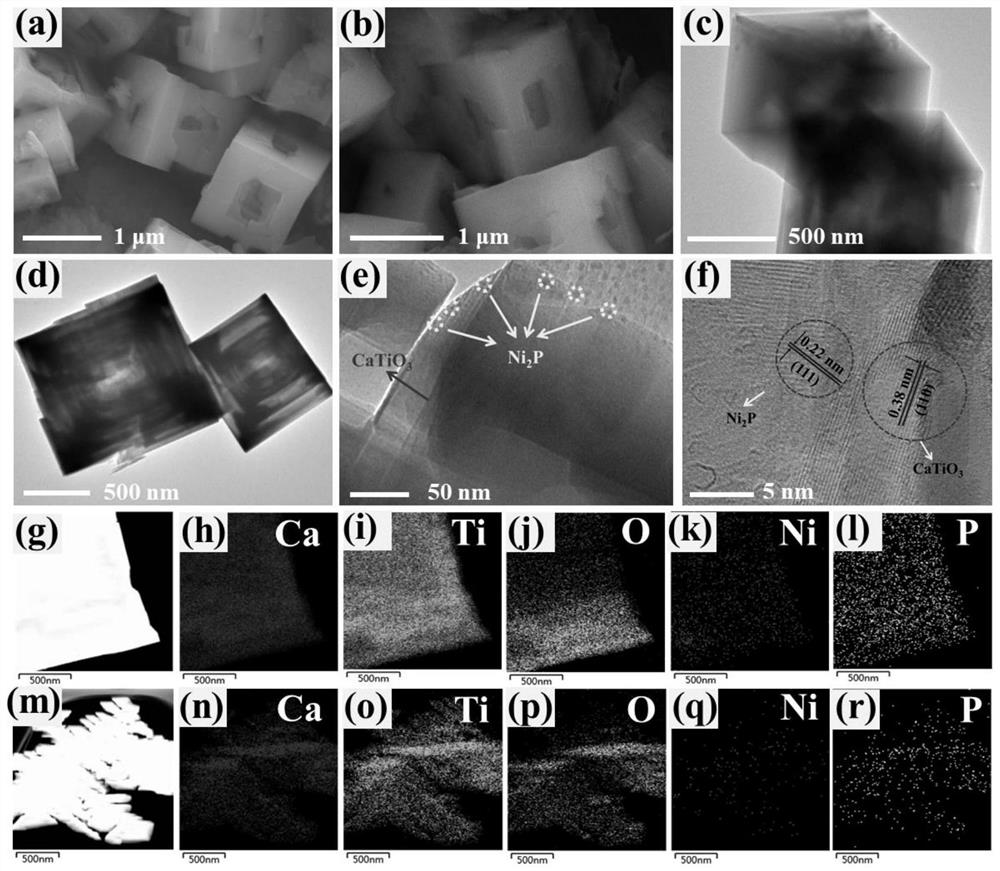

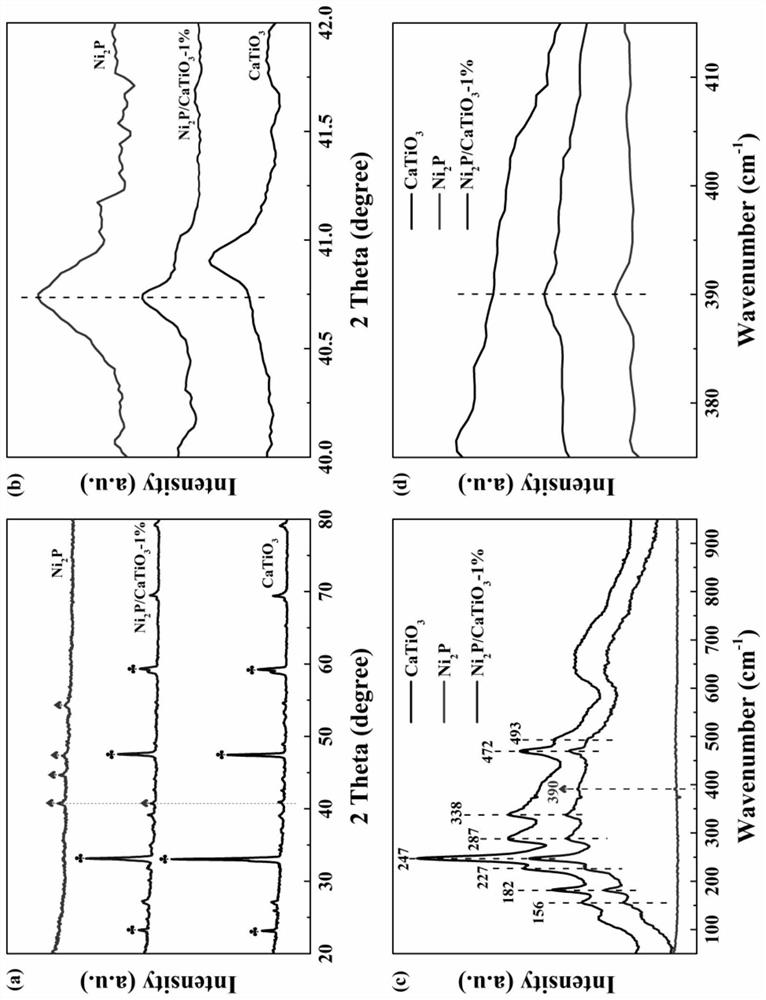

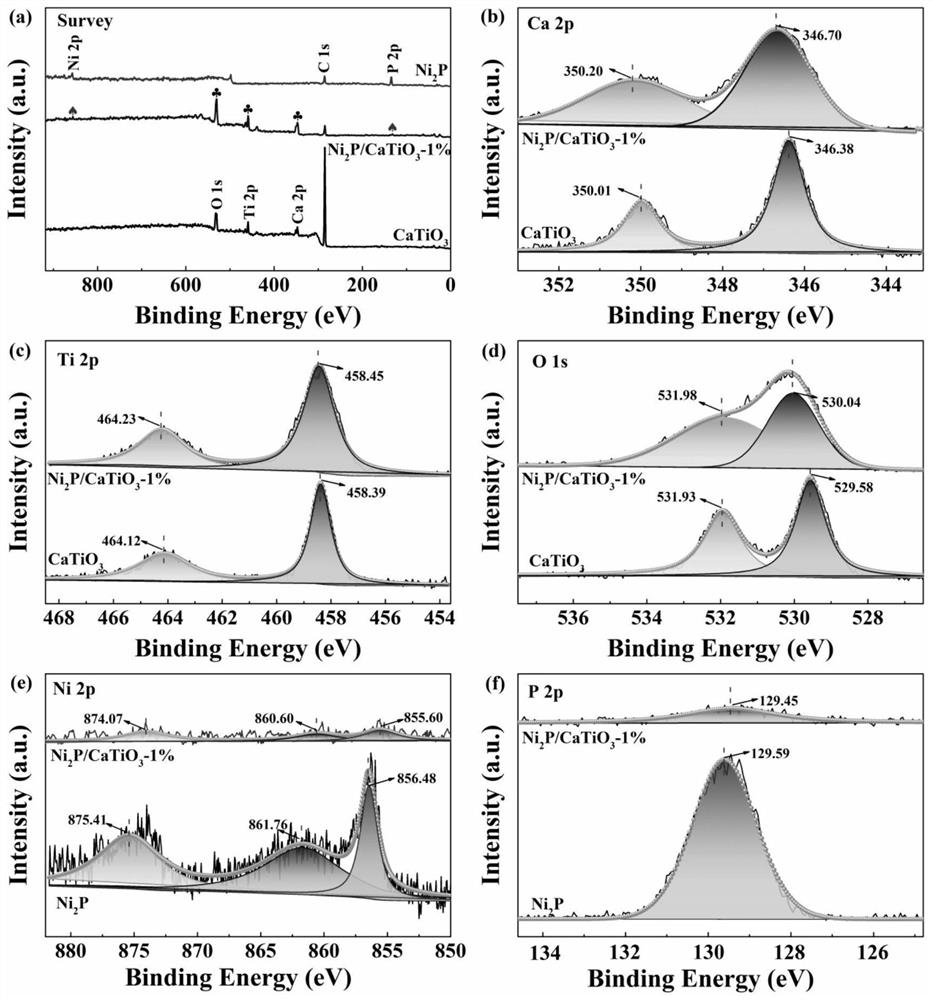

[0032] Step: Z type Ni 2 P / CaTiO 3 Preparation of heterojunction

[0033] First, 10mmol Ca(NO 3 ) 2 4H 2 O was dispersed in 30 mL deionized water. After vigorous stirring for 60 min, 3.4ml tetrabutyl titanate was added dropwise to the above solution. Then 0.02 mol of sodium hydroxide was put into it and stirred under constant magnetic force for 30 min. Finally, the Ni 2 P was dispersed in the above solution and after stirring for 30 min, the mixture was transferred to a 50 ml polytetrafluoroethylene-lined stainless steel autoclave at 200 °C for 24 h at autogenous pressure. The precipitate was washed several times by centrifugation with ethanol and deionized water. Finally, the Z-type Ni was prepared by drying 2 P / CaTiO 3 Heterojunction.

[0034] Furthermore, in composite materials, Ni 2 P and CaTiO 3 The mass ratio is 0.005:1.

[0035] Further, marked as Ni 2 P / CaTiO 3 -0.5%.

Embodiment 3

[0037] Step: Z type Ni 2 P / CaTiO 3 Preparation of heterojunction

[0038] First, 10mmol Ca(NO 3 ) 2 4H 2 O was dispersed in 30 mL deionized water. After vigorous stirring for 60 min, 3.4ml tetrabutyl titanate was added dropwise to the above solution. Then 0.02 mol of sodium hydroxide was put into it and stirred under constant magnetic force for 30 min. Finally, the Ni 2 P was dispersed in the above solution and after stirring for 30 min, the mixture was transferred to a 50 ml Teflon-lined stainless steel autoclave at 200°C for 24 hours under autogenous pressure. The precipitate was washed several times by centrifugation with ethanol and deionized water. Finally, the Z-type Ni was prepared by drying 2 P / CaTiO 3 Heterojunction.

[0039] Furthermore, in composite materials, Ni 2 P and CaTiO 3 The mass ratio is 0.01:1.

[0040] Further, marked as Ni 2 P / CaTiO 3 -1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com