Method for forming all-ceramic dental crown by stereolithography of zirconia ceramic slurry

A technology of stereolithography and zirconia ceramics, which is applied in the field of oral restorations, can solve the problems of high material waste rate, insufficient precision, and limited shape, and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

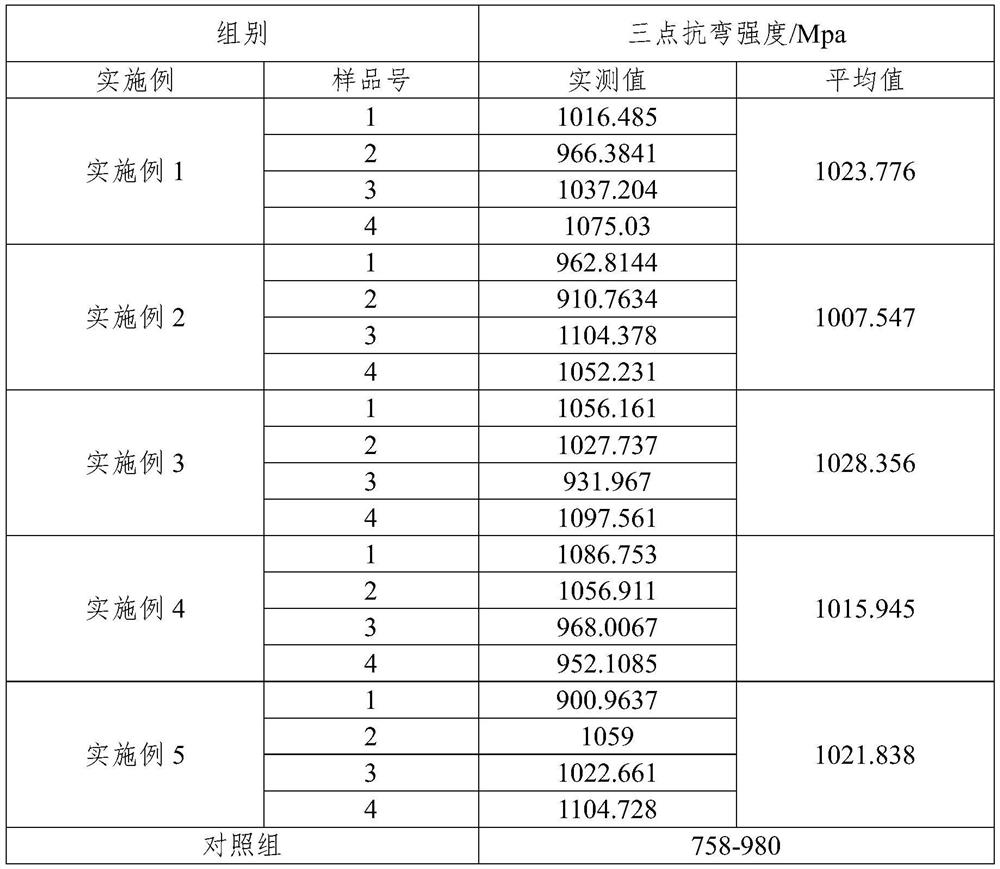

Examples

Embodiment 1

[0027] A method for forming an all-ceramic crown with zirconia ceramic slurry stereolithography, comprising the following steps:

[0028] S1: Accurate three-dimensional data of the patient's dentition is obtained by intraoral scanning, and the shape of the crown is personalized according to the three-dimensional data of the dentition, and the three-dimensional data of the crown is saved.

[0029] S2: Import the three-dimensional data of the crown into the typesetting software of the stereolithography 3D printer, and set up the support structure, and use the digital light processing method to form the zirconia ceramic slurry into a green body on the support structure according to the three-dimensional data of the typesetting crown. Obtain a solid zirconia crown green body containing organic components, control the printing layer thickness to 25-100 microns, and the energy to 20-90mW / cm 2 . The preparation method of the zirconia ceramic slurry is as follows: adding zirconia cer...

Embodiment 2

[0036] A method for forming an all-ceramic crown with zirconia ceramic slurry stereolithography, comprising the following steps:

[0037] S1: Accurate three-dimensional data of the patient's dentition is obtained by intraoral scanning, and the shape of the crown is personalized according to the three-dimensional data of the dentition, and the three-dimensional data of the crown is saved.

[0038] S2: Import the three-dimensional data of the crown into the typesetting software of the stereolithography 3D printer, and set up the support structure, and use the digital light processing method to form the zirconia ceramic slurry into a green body on the support structure according to the three-dimensional data of the typesetting crown. Obtain a solid zirconia crown green body containing organic components, control the printing layer thickness to 25-100 microns, and the energy to 20-90mW / cm 2 . The preparation method of the zirconia ceramic slurry is as follows: adding zirconia cer...

Embodiment 3

[0044] A method for forming an all-ceramic crown with zirconia ceramic slurry stereolithography, comprising the following steps:

[0045] S1: Obtain a solid impression of the crown, and scan the plaster model after pouring plaster to obtain the three-dimensional data of the crown.

[0046] S2: Import the three-dimensional data of the crown into the typesetting software of the stereolithography 3D printer, and set up the support structure, and use the digital light processing method to form the zirconia ceramic slurry into a green body on the support structure according to the three-dimensional data of the typesetting crown. Obtain a solid zirconia crown green body containing organic components, control the printing layer thickness to 25-100 microns, and the energy to 20-90mW / cm 2 . The preparation method of the zirconia ceramic slurry is as follows: adding zirconia ceramic powder, dispersant and defoamer to the photosensitive resin premix liquid, adding a photoinitiator after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com