Iron-aluminum-magnesium oxide synthetic material product and manufacturing method thereof

A technology of synthetic materials and manufacturing methods, applied in the field of inorganic non-metallic materials, can solve the problems of reduced production efficiency, harsh use conditions, short service life, etc., and achieve the effects of improving performance, improving binding force, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

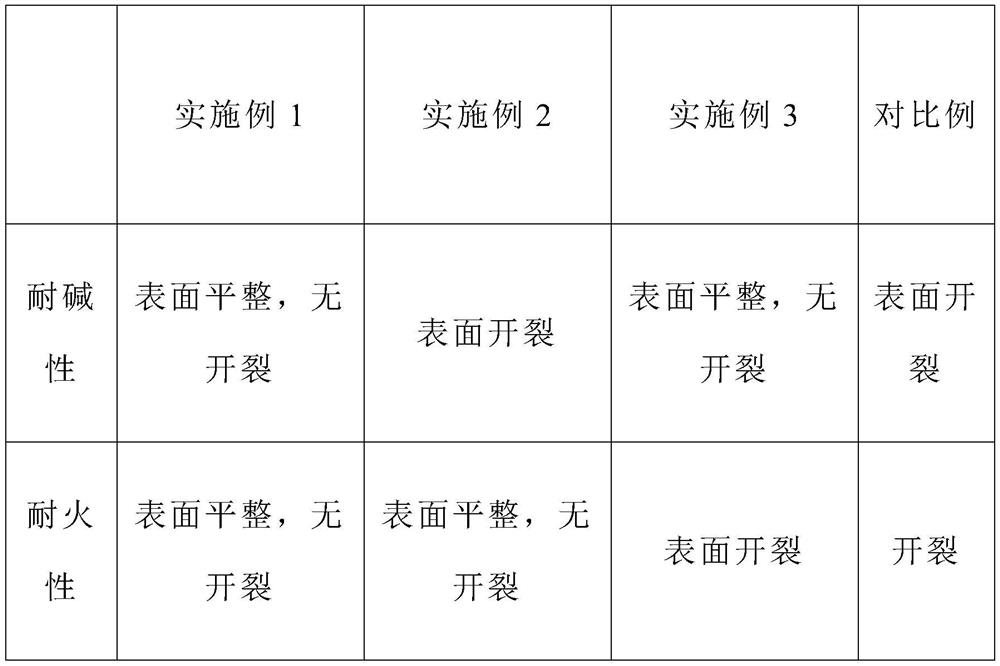

Embodiment 1

[0026]An iron-aluminum-magnesium oxide composite material product, in parts by weight, mainly includes: 40 parts of 4-1mm fused iron-aluminum-magnesium oxide composite material, 15 parts of 1-0mm fused iron-aluminum-magnesium oxide composite Materials, 15 parts of 0.045-0mm fused iron aluminum magnesium oxide synthetic material, 10 parts of hematite, 10 parts of calcium oxide clinker and 10 parts of mixed dextrin liquid.

[0027]A manufacturing method of iron-aluminum-magnesium oxide synthetic material products mainly includes the following steps:

[0028](1) The 4-1mm fused iron aluminum magnesium oxide composite material, the 1-0mm fused iron aluminum magnesium oxide composite material and the 0.045-0mm fused iron aluminum magnesium oxide composite material according to the mass ratio of 10: 3:3 After mixing in a blender and stirring evenly, add 4-1mm fused iron aluminum magnesium oxide synthetic material to the blender 0.25 times the mass of hematite and 4-1mm fused iron aluminum magne...

Embodiment 2

[0037]An iron-aluminum-magnesium oxide composite material product, in parts by weight, mainly includes: 40 parts of 4-1mm fused iron-aluminum-magnesium oxide composite material, 15 parts of 1-0mm fused iron-aluminum-magnesium oxide composite Materials, 15 parts of 0.045-0mm fused iron aluminum magnesium oxide synthetic material, 10 parts of hematite, 10 parts of calcium oxide clinker and 10 parts of mixed dextrin liquid.

[0038]A manufacturing method of iron-aluminum-magnesium oxide synthetic material products mainly includes the following steps:

[0039](1) The 4-1mm fused iron aluminum magnesium oxide composite material, the 1-0mm fused iron aluminum magnesium oxide composite material and the 0.045-0mm fused iron aluminum magnesium oxide composite material according to the mass ratio of 10: 3:3 After mixing in a blender and stirring evenly, add 4-1mm fused iron aluminum magnesium oxide synthetic material to the blender 0.25 times the mass of hematite and 4-1mm fused iron aluminum magne...

Embodiment 3

[0048]An iron-aluminum-magnesium oxide composite material product, in parts by weight, mainly includes: 40 parts of 4-1mm fused iron-aluminum-magnesium oxide composite material, 15 parts of 1-0mm fused iron-aluminum-magnesium oxide composite Materials, 15 parts of 0.045-0mm fused iron aluminum magnesium oxide synthetic material, 10 parts of hematite, 10 parts of calcium oxide clinker and 10 parts of mixed dextrin liquid.

[0049]A manufacturing method of iron-aluminum-magnesium oxide synthetic material products mainly includes the following steps:

[0050](1) The 4-1mm fused iron aluminum magnesium oxide composite material, the 1-0mm fused iron aluminum magnesium oxide composite material and the 0.045-0mm fused iron aluminum magnesium oxide composite material according to the mass ratio of 10: 3:3 After mixing in a blender and stirring evenly, add 4-1mm fused iron aluminum magnesium oxide synthetic material to the blender 0.25 times the mass of hematite and 4-1mm fused iron aluminum magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com