Synthesis method of 3-chloropropionyl chloride

A synthetic method, the technology of chloropropionyl chloride, applied in the direction of chemical instruments and methods, preparation of organic compounds, carboxylate preparation, etc., can solve problems such as difficult handling, harsh conditions, increased cost, etc., and achieve high product content and equipment efficiency High effect with less input equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

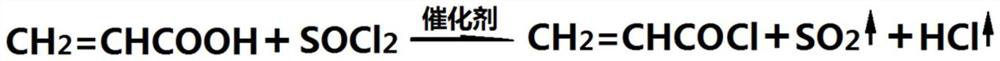

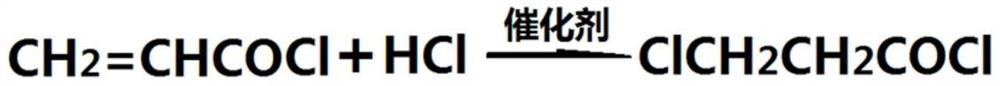

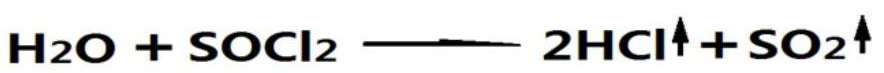

Method used

Image

Examples

Embodiment 2

[0045] The operation steps of this example are as follows: Add 600 grams (8.33 mol) of acrylic acid, 12 grams of N,N-dimethylacetamide, water 20 grams (1.11mol), stirring, water bath control dropwise temperature 60-70°C, dropwise add 1200g thionyl chloride (10.0mol); after dropwise addition, stir at 60-70°C for 1 hour, sample gas chromatography ; Under a vacuum of 0.09MPa, the distillate at 58-62°C was collected to obtain 962.9 grams of 3-chloropropionyl chloride, with a content of 99.1% and a yield of 90.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com