Preparation method of rubber accelerator CBS

A rubber accelerator and accelerator technology, applied in the field of rubber accelerator CBS preparation, can solve the problems of restricting the process of large-scale production, high water treatment costs, low product yield, etc., and achieve cost saving, process safety, and salt-containing low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

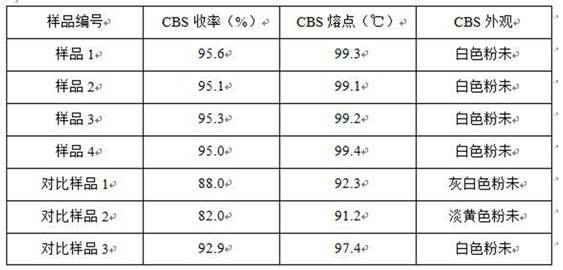

Examples

preparation example Construction

[0021] The invention discloses a preparation method of a rubber accelerator CBS, the steps are as follows:

[0022] Step 1: mix a certain quality of accelerator M and a certain volume of water in the stirred tank and transport them to the reactor, add cyclohexylamine to the reactor and stir to generate M-cyclohexylamine salt;

[0023] Step 2: At a certain temperature, drop a certain volume of hydrogen peroxide into the reactor at a certain speed, then dropwise add sodium hypochlorite, use a display indicator to detect the end point of the oxidation reaction, and stop dripping sodium hypochlorite after the oxidation is completed;

[0024] Step 3: The reacted material is subjected to solid-liquid separation, washing and drying to obtain the finished product CBS.

[0025] After beating the accelerator M with water, mix it with cyclohexylamine in the kettle to ensure that the accelerator M reacts with cyclohexylamine to generate M-cyclohexylamine salt, and ensure that it fully rea...

Embodiment 1

[0035] The present embodiment provides the preparation method of rubber accelerator CBS of the present invention, specifically:

[0036] Put 500 kg of accelerator M and 1000 L of water into the stirring tank and mix evenly, and transport it to the reaction tank through the transfer pump, add the total mass of cyclohexylamine and cyclohexylamine to be 750 kg, stir for 2.0 h, and then control The temperature in the reaction kettle is 25-35°C, add 1000 L of hydrogen peroxide with a mass concentration of 8% to the reaction kettle dropwise, and the dropping speed is controlled at 400 L / h. % sodium hypochlorite, take the solution halfway and use starch potassium iodide and ammonium sulfate reagents to test, when the reagent turns blue, stop adding sodium hypochlorite dropwise, unload the reacted material into the solid-liquid separator, wash and separate, and dry the obtained solid semi-finished product The finished product CBS is obtained, and the obtained liquid is distilled to re...

Embodiment 2

[0038] The present embodiment provides the preparation method of rubber accelerator CBS of the present invention, specifically:

[0039] Put 500 kg of accelerator M and 1000 L of water into the stirring tank and mix evenly, transport it to the reaction tank through the transfer pump, add and recover the total mass of cyclohexylamine and cyclohexylamine to be 750 kg, stir for 1.5 h, and then control The temperature inside the reactor is 35-45°C, add 1000 L of hydrogen peroxide with a mass concentration of 9% to the reactor dropwise, and the rate of addition is controlled at 450 L / h. % sodium hypochlorite, take the solution halfway and use starch potassium iodide and ammonium sulfate reagents to test, when the reagent turns blue, stop adding sodium hypochlorite dropwise, unload the reacted material into the solid-liquid separator, wash and separate, and dry the obtained solid semi-finished product The finished product CBS is obtained, and the obtained liquid is distilled to reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com