Self-repairing waterborne polyurethane-polyacrylic acid emulsion and preparation method thereof

A technology of polyacrylic acid emulsion and water-based polyurethane, which is applied in the direction of coating, etc., can solve the problems of shortening the service life of materials, becoming sticky at high temperature, poor tensile performance, etc., and achieves the effect of strong self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

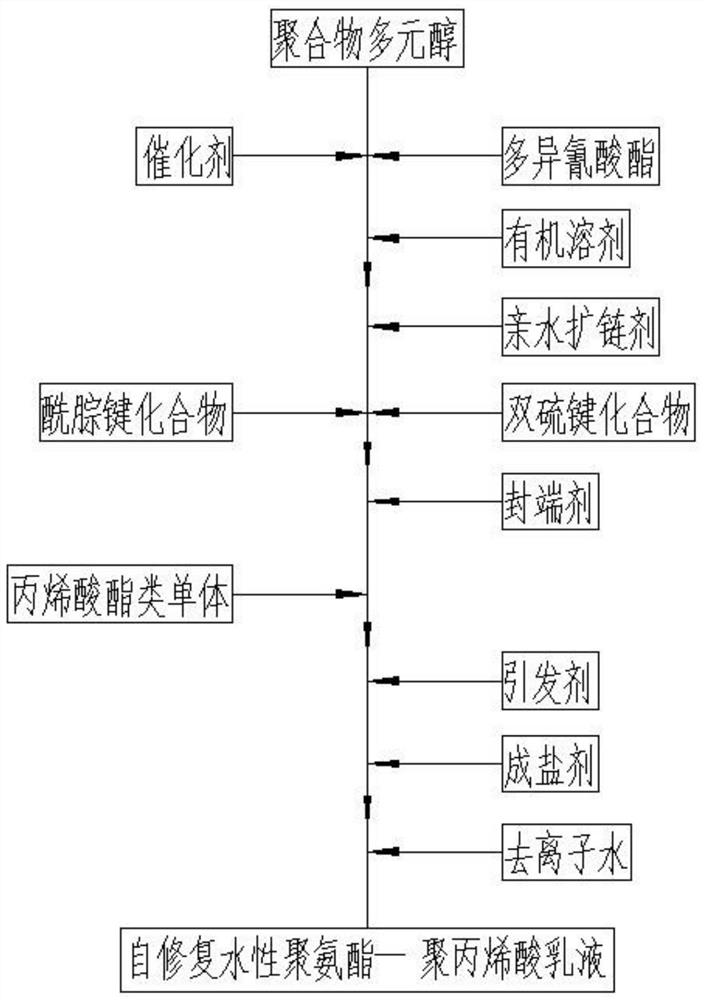

[0028] Such as figure 1 as shown, figure 1 It is a flowchart of the preparation method of the self-healing waterborne polyurethane-polyacrylic acid emulsion. The preparation method of self-repairing water-based polyurethane-polyacrylic acid emulsion of the present invention, raw material is measured in parts by mass, comprises the steps:

[0029] S1, heating 60-120 parts of polymer polyol to 100°C-130°C, vacuum dehydration for 1h-2h;

[0030] S2, carry out nitrogen protection on the solution obtained in step S1, and lower the temperature to 60°C-90°C, add 30-60 parts of polyisocyanate and 0.01-0.03 parts of catalyst, react for 1h-3h, add 30-60 parts of organic solvent to adjust the viscosity ;

[0031] S3, adding 5 to 10 parts of a hydrophilic chain extender to the solution obtained in step S2, and reacting at 50°C to 90°C for 1h to 3h;

[0032] S4, adding 5 to 15 parts of disulfide bond compounds and 5 to 10 parts of acylhydrazone bond compounds to the solution obtained i...

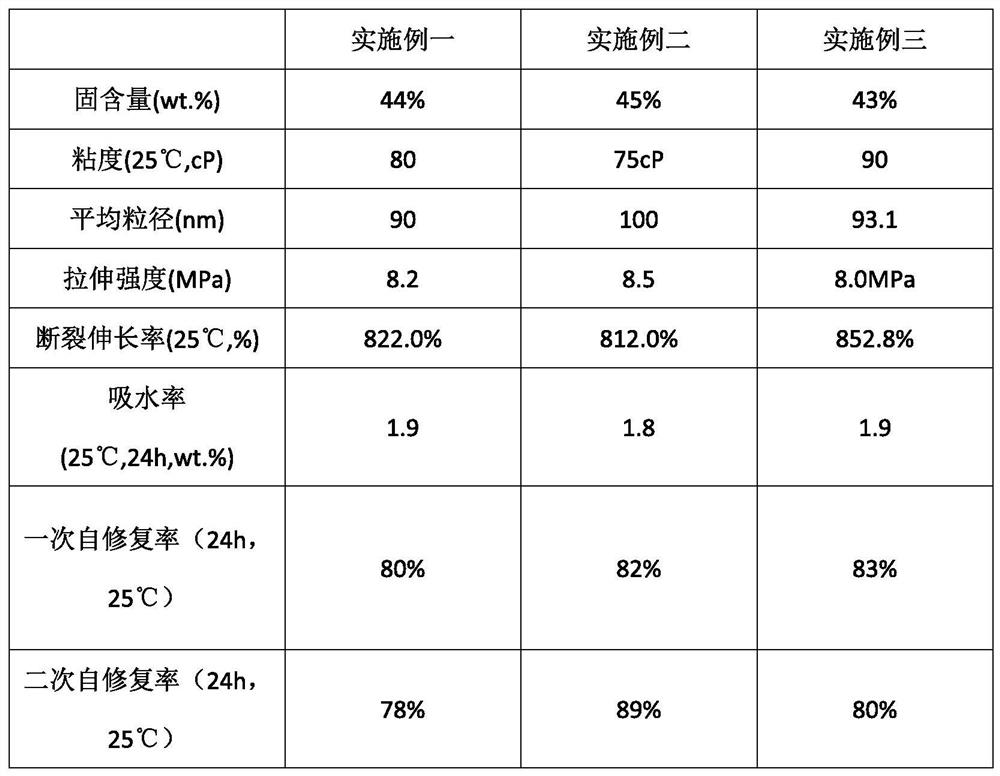

Embodiment 1

[0051] The preparation method of the self-repairing water-based polyurethane-polyacrylic acid emulsion, raw materials in parts by mass, comprises the steps:

[0052] S1, add 100 parts of polytetrahydrofuran diol into the reactor, and perform vacuum dehydration at 120°C for 2 hours;

[0053] S2, at N 2 Under protection, lower the temperature to 80°C, add 44.5 parts of isophorone diisocyanate and 0.03 parts of dibutyltin dilaurate, react at 90°C for 3 hours, and adjust the viscosity with 40 parts of N-methylpyrrolidone;

[0054] S3, lower the temperature to 70°C, add 8 parts of sodium N-(2-aminoethyl)-2-aminoethanesulfonate and react for 3h

[0055] S4, cooling down to 50°C, adding 10 parts of 4,4′-diaminodiphenylsulfide and 5 parts of quinone oxime hydrazone to react for 2 hours;

[0056] S5, add 10 parts of hydroxyethyl methacrylate (HEMA), and react at 90° C. for 3 hours;

[0057] S6, add 10 parts of acrylic acid, 20 parts of acrylate, 30 parts of methyl methacrylate, 0.01...

Embodiment 2

[0063] The preparation method of the self-repairing water-based polyurethane-polyacrylic acid emulsion, raw materials in parts by mass, comprises the steps:

[0064] S1, add 100 parts of polycaprolactone diol into the reactor, and perform vacuum dehydration at 120°C for 2 hours;

[0065] S2, at N 2 Under protection, lower the temperature to 70°C, add 50 parts of 4,4-diphenylmethane diisocyanate (MDI) and 0.02 parts of stannous octoate, react at 85°C for 3 hours, and adjust the viscosity with 40 parts of 20ml dioxane;

[0066] S3, lower the temperature to 70°C, add 10 parts of sodium ethylenediaminoethanesulfonate and react for 3 hours;

[0067] S4, heating up to 50°C, adding 12 parts of 4,4′-dihydroxydiphenylsulfide and 6 parts of difenpyrofen, and reacting for 3 hours;

[0068] S5, add 10 parts of hydroxyethyl acrylate (HEA), and react at 90° C. for 2 hours;

[0069] S6, add 10 parts of acrylic acid (AA), 20 parts of methyl methacrylate, 20 parts of styrene, 0.010 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com