Hydrothermal preparation method of mullite coated particles

A technology of mullite and encapsulation, which is applied in the direction of chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of encapsulation shell damage, technical difficulty, inapplicability of encapsulation of red pigments, etc., to reduce production costs, Avoid the effect of reunion growing up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

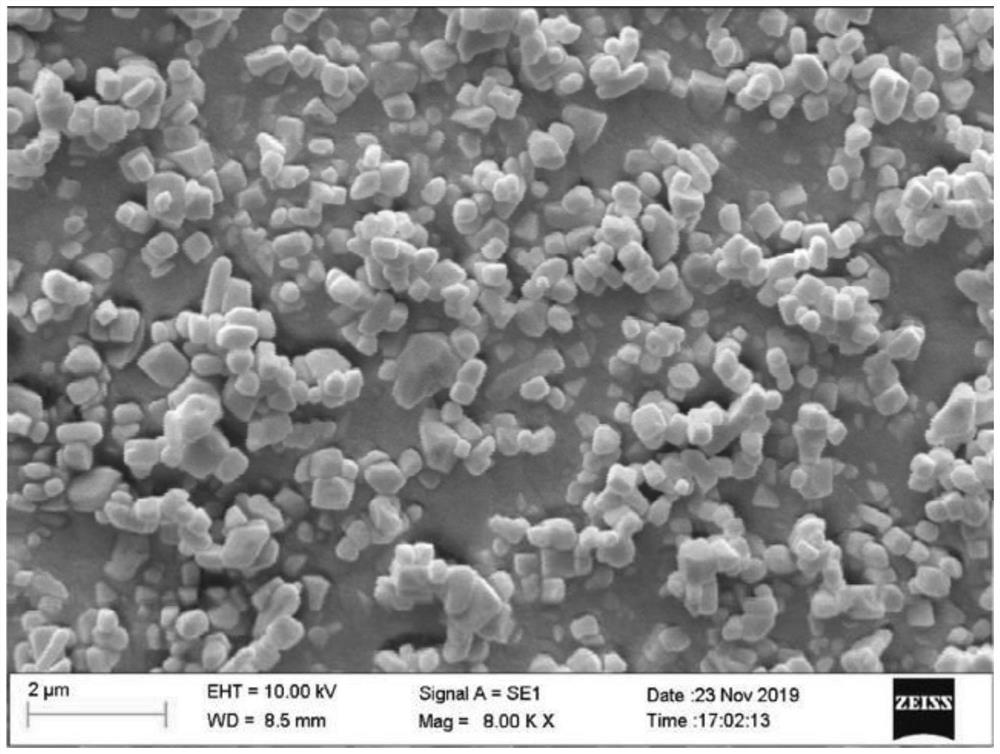

[0070] A hydrothermal preparation method for mullite-coated particles, comprising:

[0071] Sa-1) Precursor liquid configuration: mix the aluminum salt, additives and part of the precursor salt of the particles to be coated, and adjust the pH of the mixture;

[0072] Sa-2) The first hydrothermal reaction: transfer the precursor liquid to the hydrothermal kettle, and hydrothermally react to obtain amorphous alumina slurry;

[0073] Sa-3) The second hydrothermal reaction: add the remaining precursor salt solution of the particles to be coated into the amorphous alumina slurry, and perform the second hydrothermal reaction to obtain particles coated with amorphous alumina;

[0074] Sa-4) The third hydrothermal reaction: add a silicon source to the slurry of amorphous alumina-coated particles, adjust the pH, and perform the third hydrothermal reaction after coating the surface of amorphous alumina with amorphous silicon hydroxide reaction to obtain mullite-coated particle slurry; ...

Embodiment 1

[0124] (1) Prepare a mixed solution of cadmium salt, aluminum salt, thiourea, urea, and naphthalene-based dispersant and adjust the pH to 3 with acid. Among them, the concentration of aluminum salt is 2mol / L, the concentration of cadmium salt is 0.005mol / L, and the concentration of thiourea The concentration is 0.005mol / L, and the concentration of urea is 3mol / L;

[0125] (2) Pour the mixed weak acid solution obtained in (1) into a hydrothermal kettle, keep it at 110°C for 24 hours, and perform the first hydrothermal reaction;

[0126] (3) Mole ratio Se: (NH 4 ) 2 S:Cd=0.2: 0.2:1 dissolving selenium powder in ammonium sulfide liquid to form selenium-soluble ammonium sulfide liquid;

[0127] (4) Pour the solution obtained in (3) into the slurry obtained in (2), keep it warm at 120°C for 24 hours, and carry out the second hydrothermal reaction, so that selenium can penetrate into cadmium sulfide to form a porous amorphous alumina coating. cadmium selenide sulfide slurry

[0...

Embodiment 2

[0133] (1) Prepare a mixed solution of cadmium salt, aluminum salt, thiourea, urea, and sulfamic acid dispersant and adjust the pH to 3 with acid, wherein the concentration of aluminum salt is 2mol / L, the concentration of cadmium salt is 0.01mol / L, and the concentration of sulfur The concentration of urea is 0.01mol / L, and the concentration of urea is 3mol / L;

[0134] (2) Pour the mixed weak acid solution obtained in (1) into a hydrothermal kettle, keep it at 100°C for 12 hours, and perform the first hydrothermal reaction;

[0135] (3) Mole ratio Se:Na 2 S:Cd=0.3: 0.3:1 dissolving selenium powder in ammonium sulfide liquid to form selenium-soluble ammonium sulfide liquid;

[0136] (4) Pour the solution obtained in (3) into the slurry obtained in (2), keep it warm at 120°C for 12 hours, and carry out the second hydrothermal reaction;

[0137] (5) Add water glass and ammonium fluoride to the slurry obtained in (4) according to the molar ratio Si:Al:F=2:3:0.01, and adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

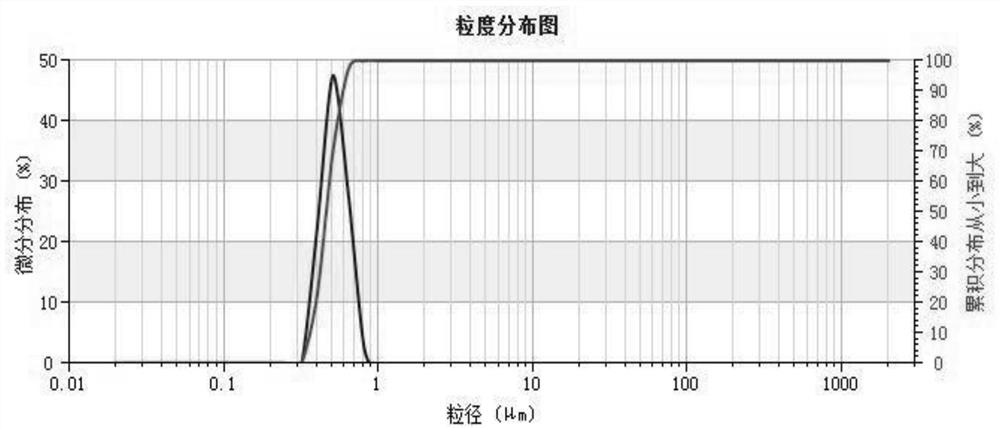

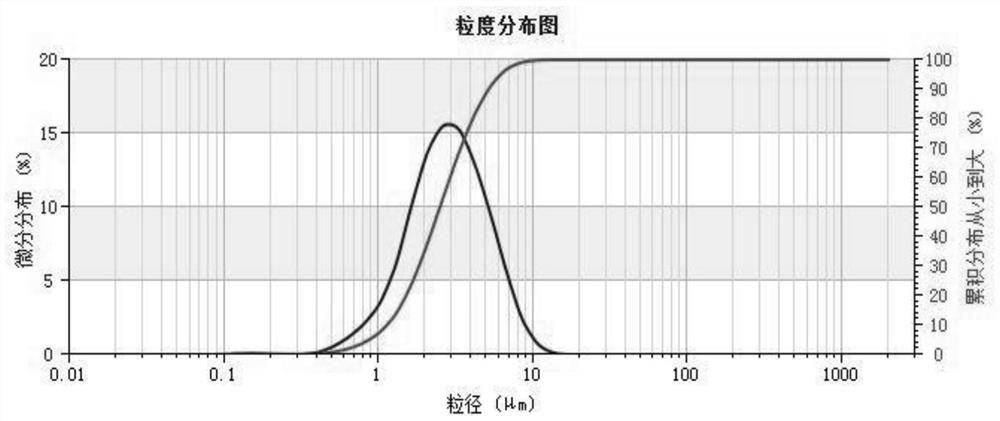

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com