Core-shell structure sulfur cathode material, preparation method and application in lithium-sulfur batteries

A sulfur cathode material, core-shell structure technology, applied in lithium batteries, nanotechnology for materials and surface science, positive electrodes, etc. The effect of high electrical conductivity and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

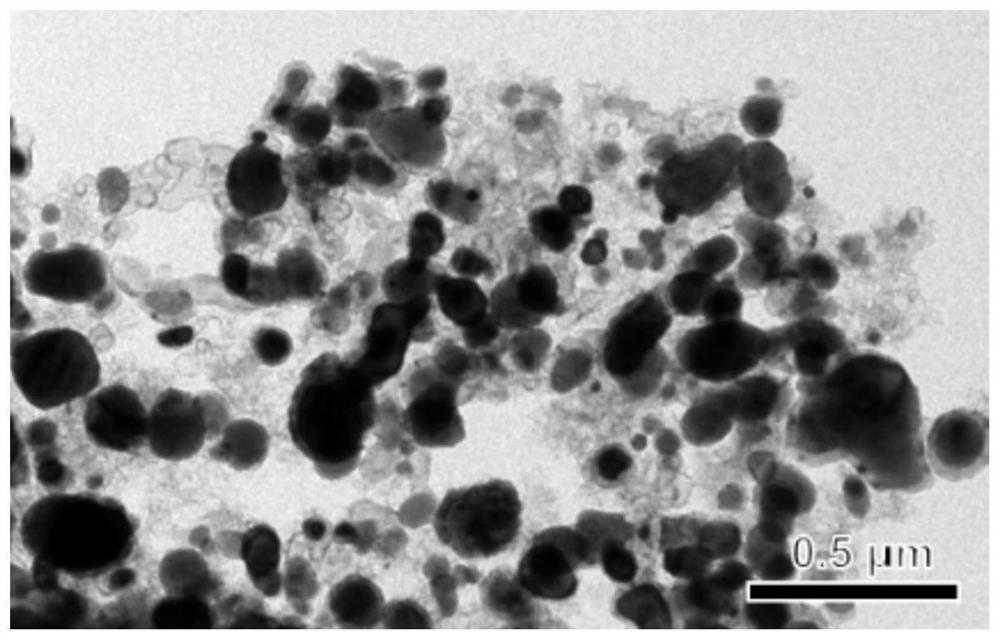

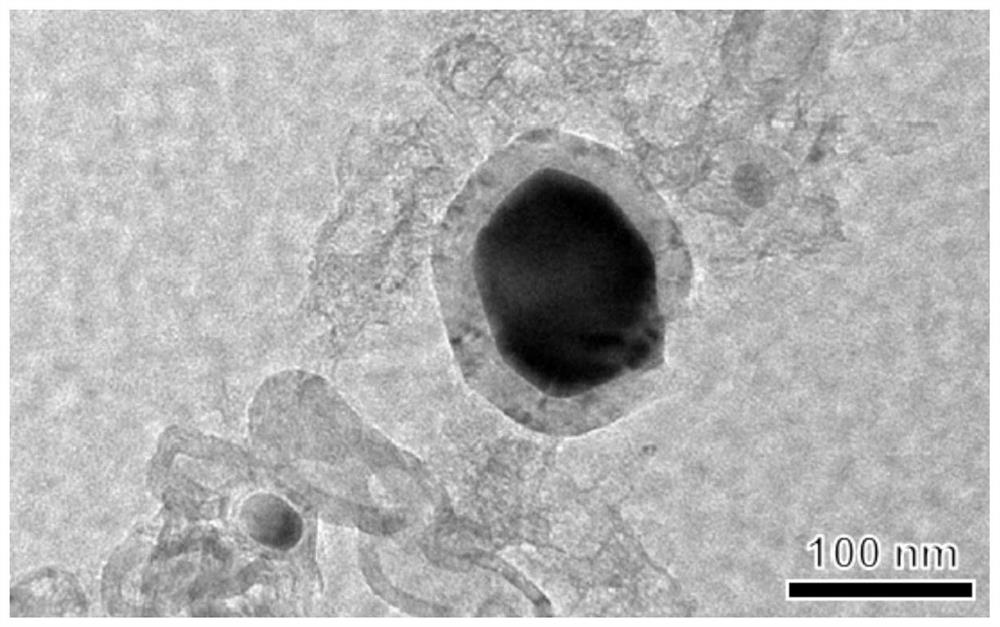

[0061] This embodiment provides a sulfur cathode material, the sulfur cathode material is Fe coated with carbon 3 o 4 Materials loaded with sulfur, denoted as S / C@Fe 3 o 4 .

[0062] (1) C@Fe 3 o 4 Preparation of:

[0063] S1, to 1.21g Fe(NO 3 ) 3 9H 2 O and 0.42g of tribenzoic acid (BTC) were added to 20ml of ethanol respectively, and after stirring for 30mins, after the two showed a yellow-brown transparent solution and a colorless transparent solution respectively, the two were mixed, and a brown-yellow hydrogel was formed immediately ;

[0064] S2, aging at normal temperature for 24h, so that the two react more fully;

[0065] S3. Wash off the incompletely reacted small molecules with ethanol and distilled water, then freeze the hydrogel at -20°C for 48h, and then transfer it to a freeze dryer for drying. The parameters at this time are -40°C, 35pa pressure, 48h Afterwards, it is brown-yellow powder;

[0066] S4. In the tube furnace, under the protection of argon...

Embodiment 2

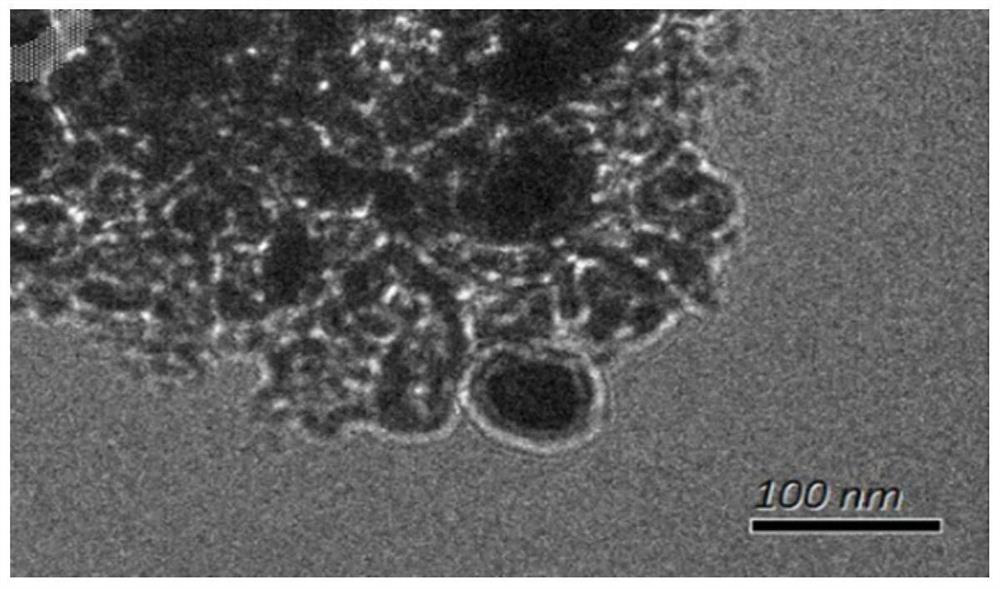

[0085] This embodiment provides a sulfur cathode material, the sulfur host material is carbon-coated Fe etched by hydrochloric acid 3 o 4 The obtained core-shell structure YSC@Fe 3 o 4 , and uniformly named it YCF. According to its remaining Fe 3 o 4 The content is named as YCF-28, and the sulfur cathode after sulfur loading is S / YCF-28.

[0086] The method for preparing the sulfur cathode material used in this embodiment includes the following steps:

[0087] (1) C@Fe 3 o 4 Preparation of nanospheres: same as Example 1.

[0088] (2) Preparation of core-shell structure YCF nanocages:

[0089] S1. Take 1g of C@Fe 3 o 4 The powder was dispersed in 50mL of deionized water, ultrasonically dispersed at a frequency of 100kW for 30min, 66mL of hydrochloric acid (36% in mass fraction) was added, reacted for 2h, and the core-shell structure YCF-28 nanocages were obtained after vacuum filtration. The material was washed to pH ≈ 6-8, and dried in a vacuum oven at 60°C for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com