Medical Zn-Cu-Mn-Zr alloy capable of being degraded in living body and high in strength and toughness

A zn-cu-mn-zr, biological technology, applied in prosthesis, medical science, surgery, etc., can solve problems such as aging work hardening ability of zinc alloy, achieve good biocompatibility, improve mechanical properties, avoid Pain and Burden Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

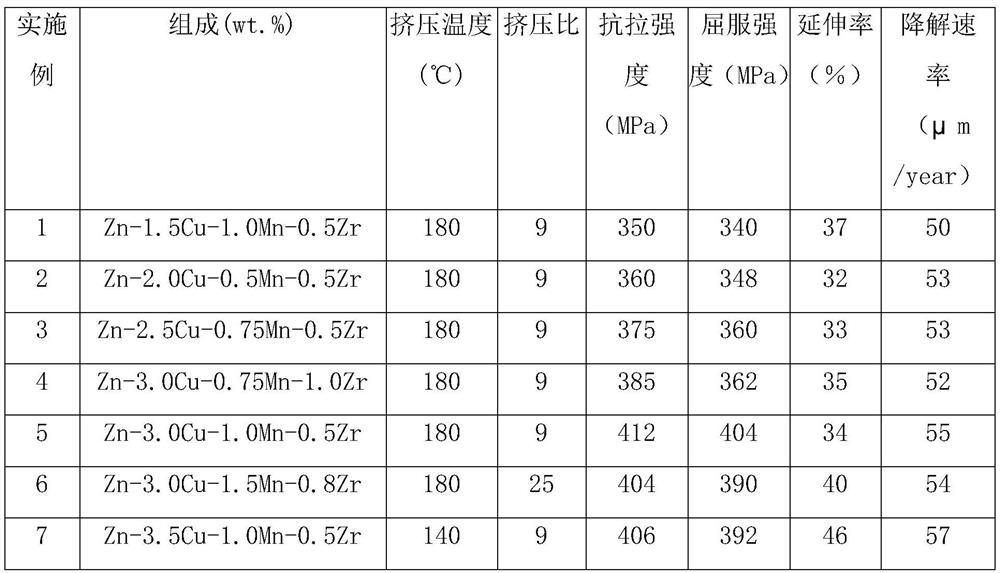

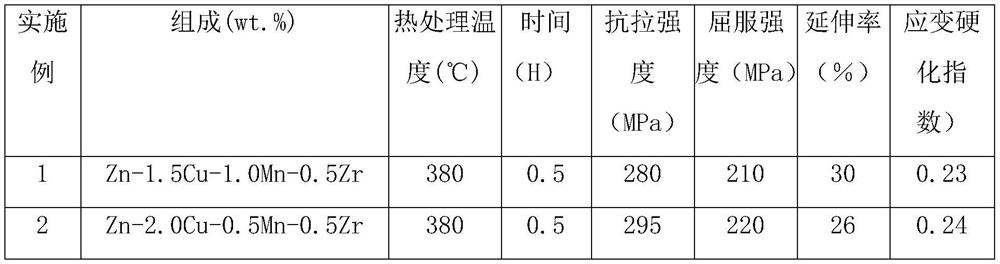

Embodiment 1

[0043] Alloy composition Zn-1.5Cu-1.0Mn-0.5Zr. Cut a certain length of ingot, after 400℃, 24h solid solution treatment, extrusion into The extrusion temperature is 180°C and the extrusion ratio is 9. At room temperature and a tensile strain rate of 1×10 -3 Under certain test conditions, the mechanical properties that can be obtained under this process are: the tensile strength is 350MPa, the yield strength is 340MPa, and the elongation is 37%. The corrosion rate of the material in the C-SBF simulated body fluid environment is 50 μm / year. Biological test results show that the material has no obvious cytotoxicity and good biocompatibility. The antibacterial rates of Staphylococcus aureus and Escherichia coli were all above 90%. After the extruded alloy is kept at 380°C for 0.5 hours, the yield strength of the alloy is 210MPa, the tensile strength is 280MPa, the elongation is 30%, and the strain hardening exponent n is 0.23 at the stage of true strain 5%-15%. The alloy has ...

Embodiment 2

[0045] Alloy composition Zn-2.0Cu-0.5Mn-0.5Zr. Cut a certain length of ingot, after 400℃, 24h solid solution treatment, extrusion into The extrusion temperature is 180°C and the extrusion ratio is 9. At room temperature and a tensile strain rate of 1×10 -3 Under certain test conditions, the mechanical properties that can be obtained under this process are: the tensile strength is 360MPa, the yield strength is 348MPa, and the elongation is 32%. The corrosion rate of the material in the C-SBF simulated body fluid environment is 53 μm / year. Biological test results show that the material has no obvious cytotoxicity and good biocompatibility. The antibacterial rates of Staphylococcus aureus and Escherichia coli were all above 90%. After the extruded alloy is kept at 380°C for 0.5 hours, the yield strength of the alloy is 220MPa, the tensile strength is 295MPa, the elongation is 26%, and the strain hardening exponent n is 0.24 at the stage of true strain 5%-15%. The alloy has ...

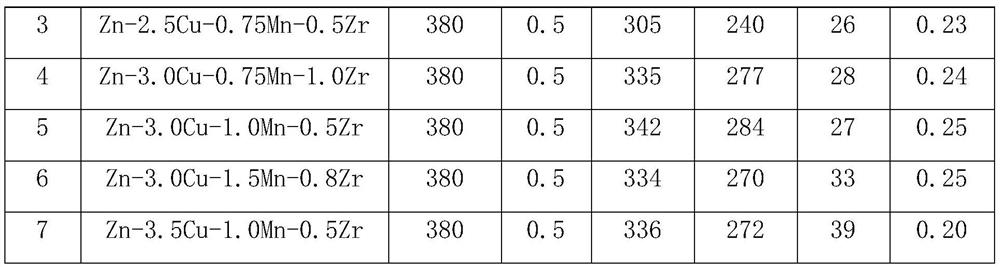

Embodiment 3

[0047] Alloy composition Zn-2.5Cu-0.75Mn-0.5Zr. Cut a certain length of ingot, after 400℃, 24h solid solution treatment, extrusion into The extrusion temperature is 180°C and the extrusion ratio is 9. At room temperature and a tensile strain rate of 1×10 -3 Under certain test conditions, the mechanical properties that can be obtained under this process are: the tensile strength is 375MPa, the yield strength is 360MPa, and the elongation is 33%. The corrosion rate of the material in the C-SBF simulated body fluid environment is 53 μm / year. Biological test results show that the material has no obvious cytotoxicity and good biocompatibility. The antibacterial rates of Staphylococcus aureus and Escherichia coli were all above 90%. After the extruded alloy is kept at 380°C for 0.5 hours, the yield strength of the alloy is 240MPa, the tensile strength is 305MPa, the elongation is 26%, and the strain hardening exponent n is 0.23 at the stage of true strain 5%-15%. The alloy has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com