Polymer-based solid electrolyte with high room-temperature ionic conductance as well as preparation method and application thereof

A technology of solid electrolyte and ion conductance, applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of difficult mass production and industrialization, poor chemical stability, poor mechanical properties, etc., to achieve Improvement of mobility, improvement of mechanical properties, effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

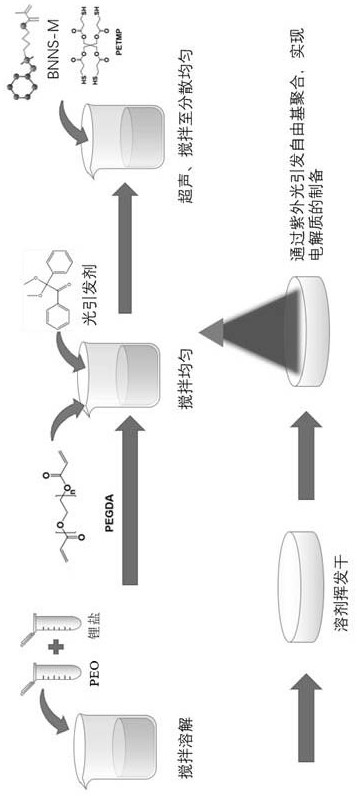

[0043] This example provides a simple method for preparing a polymer-based electrolyte with both rigidity and flexibility, such asfigure 1 As shown, the specific preparation steps are as follows:

[0044] (1) Add 0.5 g of two-dimensional hexagonal boron nitride nanosheets (h-BNNs) to isopropanol, and disperse them ultrasonically for 4 h. The edges of the hexagonal boron nitride nanosheets are modified to hydroxyl groups. The concentration of the solution is 4 mg / ml;

[0045] (2) Add the silane coupling agent KH-570 (MPS) to the dispersion obtained in (1), and ultrasonicate for 4 h at a power of 100 W. The surface of boron nitride nanosheets is grafted by MPS to obtain Boron nitride nanosheets, suction filtered and dried for later use, wherein the mass ratio of MPS to boron nitride nanosheets is 16:1;

[0046] (3) Add 0.25 g polyethylene oxide (PEO, molecular weight: 600,000) and 0.125 g LiTFSI to 10 g acetonitrile solution, stir for 12 h until uniform;

[0047] (4) Add 0.25 ...

Embodiment 2

[0054] This example provides a simple method for preparing a polymer-based electrolyte with both rigidity and flexibility. The specific preparation steps are as follows:

[0055] (1) Add 0.5 g of two-dimensional hexagonal boron nitride nanosheets (h-BNNs) to isopropanol, ultrasonicate for 4 h, the edges of hexagonal boron nitride nanosheets are modified to hydroxyl groups, and the boron nitride nanosheets solution The concentration is 4 mg / ml;

[0056] (2) Add the silane coupling agent KH-570 (MPS) to the dispersion obtained in (1), and ultrasonicate for 4 h at a power of 100 W. The surface of boron nitride nanosheets is grafted by MPS to obtain Boron nitride nanosheets, suction filtered and dried for later use, wherein the mass ratio of MPS to boron nitride nanosheets is 16:1;

[0057] (3) Add 0.25 g polyethylene oxide (PEO, molecular weight: 600,000) and 0.125 g LiTFSI to 10 g acetonitrile solution, stir for 12 h until uniform;

[0058] (4) Boron nitride nanosheets (h-BNNs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com