Copper-containing or iron-based SAPO molecular sieve SCR catalyst, as well as preparation method and application of catalyst

A molecular sieve and catalyst technology, which is applied in the preparation of molecular sieve-like microporous materials and its catalytic process application, can solve the problems of low denitrification efficiency of cold-start SCR technology, and the ability to resist hydrothermal shock cannot meet the demand, and achieve excellent activity and high temperature stability high performance, meet the requirements of wide activity window, and good low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

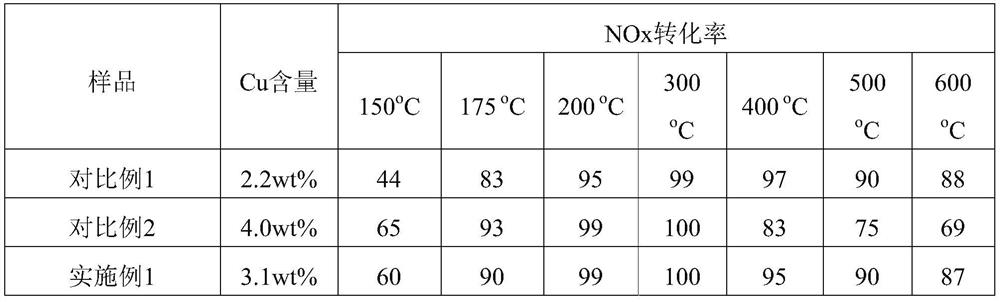

Embodiment 1

[0037] (1) Slowly add 120g of phosphoric acid (85wt%) in 500g of water, then add 70g of pseudoboehmite, 20g of 40wt% silica sol, keep the temperature at 40°C, and stir for 2 hours; then add 6.5g of acetic acid monohydrate Copper, continue to stir for 1 hour; then add 60 g of triethylamine, stir for 30 minutes; then add 35 g of morpholine, add 20 g of cyclamate, stir for 1 hour to obtain a gel mixture. Transfer the gel mixture into a closed reaction kettle, heat up to 200°C for 2 hours, react at a constant temperature for 24 hours, cool to room temperature, filter, wash the obtained product twice with deionized water, and dry at 120°C for 10 hours to obtain organic Molecular sieve powder for templating agent. The molecular sieve powder was heated up to 550°C at a rate of 1°C / min and calcined for 4 hours in an air-circulating environment to obtain a Cu-SAPO molecular sieve catalyst precursor synthesized by hydrothermal method. N 2 Adsorption isotherm test BET specific surface ...

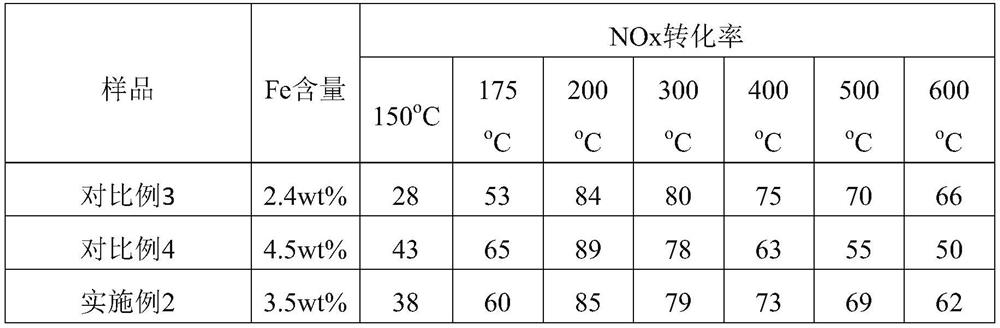

Embodiment 2

[0046] (1) Slowly add phosphoric acid (85wt%) 120g in 500g water, then add pseudoboehmite 75g, 40wt% silica sol 20g, constant temperature 40 ℃, after stirring for 2 hours; then add 11g of sulfurous acid heptahydrate Iron, continue stirring for 1 hour; then add 55 g of triethylamine and stir for 30 minutes; then add 20 g of tetraethylenepentamine and stir for 1 hour to obtain a gel mixture. Transfer the gel mixture into a closed reaction kettle, heat up to 200°C for 2 hours, react at a constant temperature for 24 hours, cool to room temperature, filter, wash the obtained product twice with deionized water, and dry at 120°C for 10 hours to obtain organic Molecular sieve powder for templating agent. The zeolite powder is heated to 550°C for 4 hours at a rate of 1°C / min in an air-circulating environment to obtain the Fe-SAPO molecular sieve catalyst precursor synthesized by hydrothermal method, N 2 Adsorption isotherm test BET specific surface area 635m 2 / g, the average pore di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com