Liquid crystal polymer film and manufacturing method thereof

A liquid crystal polymer and liquid crystal technology, applied in chemical instruments and methods, electronic equipment, layered products, etc., can solve the problem that the heat resistance and high frequency characteristics of the liquid crystal polymer film are difficult to simultaneously achieve and highlight the potential of industrial application , low energy consumption, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

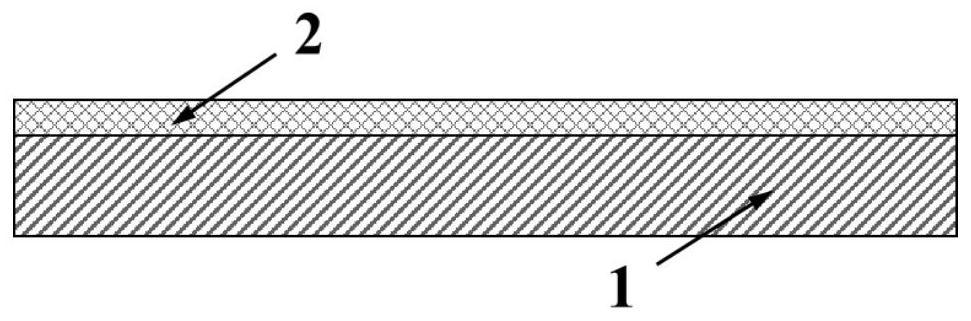

Embodiment 1

[0057] Core LCD polymer layer 1 liquid crystal polymer resin selective melting point T m1 The liquid crystal polymer resin having a lower melting point in the composite liquid crystal polymer layer 2 of 320 ° C, a liquid crystal polymer resin having a lower melting point in the composite liquid crystal polymer layer 2. m2 The liquid crystal copolyester of 280 ° C for hydroxybenzoic acid and 6-hydroxy-2-naphthoic acid; the liquid crystal polymer material is dried in a vacuum drying tank, the drying temperature is 150 ° C, the drying time is 5 hours, The water content of the resin after drying is less than 300 ppm.

[0058] Resin used by the composite liquid crystal polymer layer 2: Type T m2 The liquid crystal polymer resin accounted for the total mass percentage of the total amount of the liquid crystal polymer film is 15%, and the two liquid crystal polymers are mixed uniform, and the blended grain is blended in the same double screw extruder. The liquid crystal polymer material ...

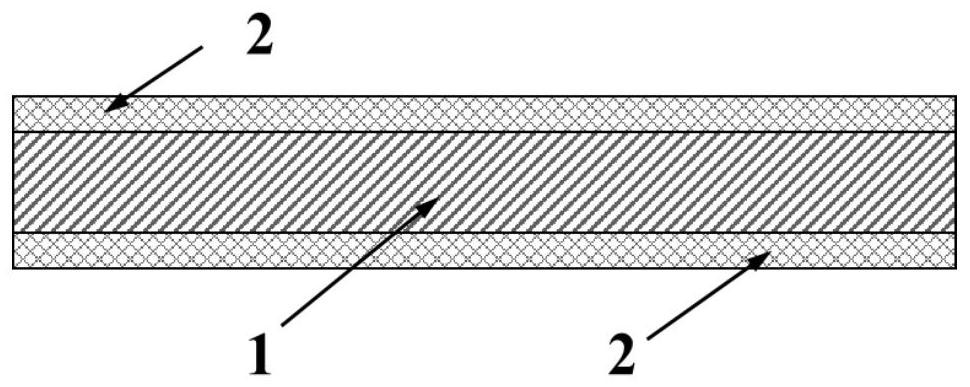

Embodiment 2

[0061] Core LCD polymer layer 1 liquid crystal polymer resin selective melting point T m1 The liquid crystal polymer resin having a lower melting point in the composite liquid crystal polymer layer 2 of 320 ° C, a liquid crystal polymer resin having a lower melting point in the composite liquid crystal polymer layer 2. m2 The liquid crystal copolyester of 280 ° C for hydroxybenzoic acid and 6-hydroxy-2-naphthoic acid; the liquid crystal polymer material is dried in a vacuum drying tank, the drying temperature is 150 ° C, the drying time is 5 hours, The water content of the resin after drying is less than 300 ppm.

[0062] Resin used by the composite liquid crystal polymer layer 2: Type T m2The liquid crystal polymer resin accounted for the total mass percentage of the total amount of the liquid crystal polymer film is 15%, and the two liquid crystal polymers are mixed uniform, and the blended grain is blended in the same double screw extruder. The liquid crystal polymer material a...

Embodiment 3

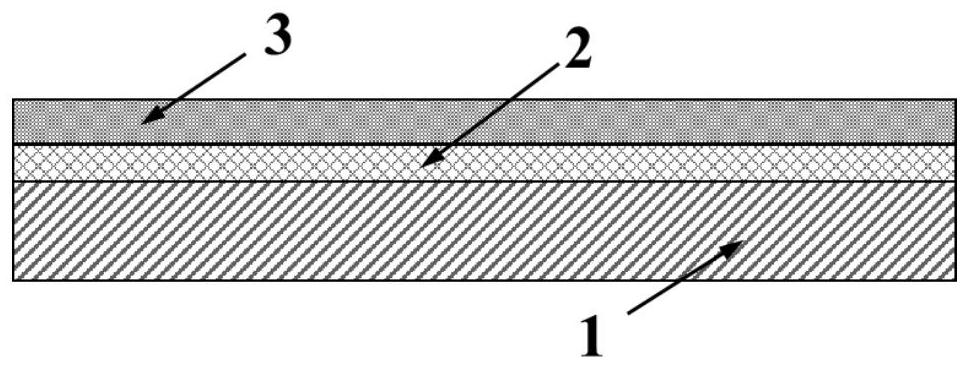

[0064] A liquid crystal polymer film having a thickness of 40 μm was prepared using the same method in Example 2; an electrolytic copper foil having a thickness of 12 μm and a surface roughness of approximately 1.5 μm were selected as a metal foil 3. According to the sequential stack of copper foil / liquid crystal polymer film, the plate hot pressing machine with a surface hardness is 90 degrees at a temperature of 295 ° C, and the pressure is 100 kg / cm. 2 The liquid crystal polymer film and the copper foil are laminated together under the conditions of 5 s, and obtain a single-sided copper flexible circuit board, such as figure 2 As shown, the composite liquid crystal polymer layer 2 bonds the copper foil to the liquid crystal polymer film as an adhesive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com