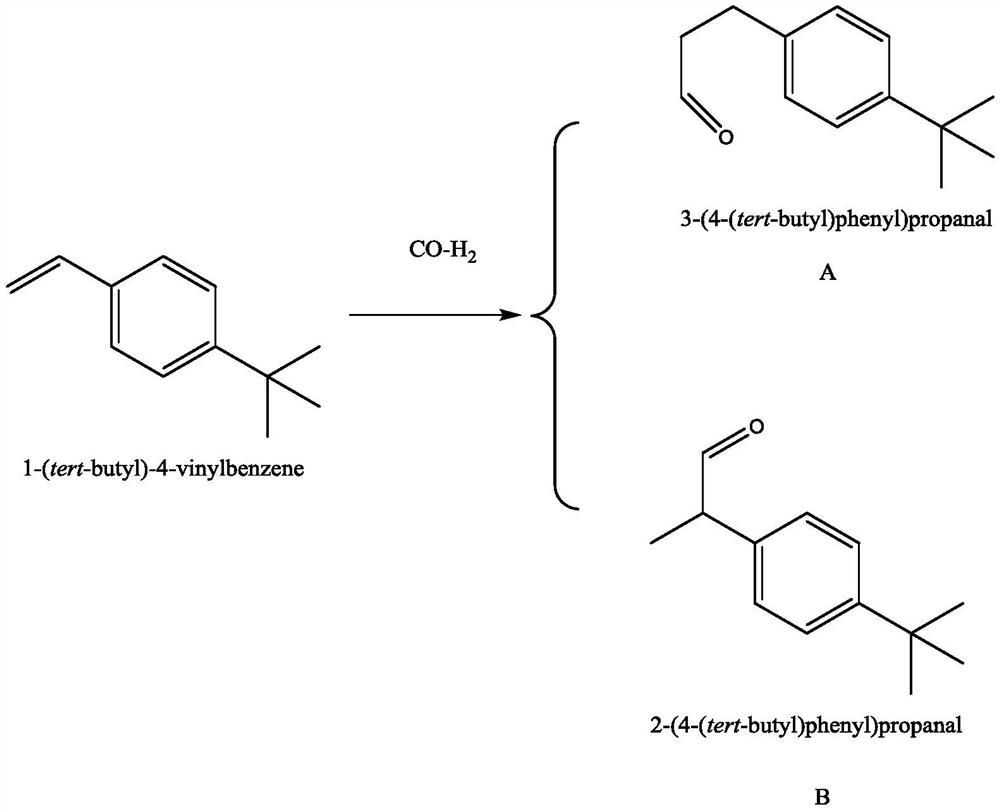

Preparation method of 4-tert-butyl phenylpropionaldehyde

A technology of tert-butylphenylpropionaldehyde and tert-butylstyrene, which is applied in the field of preparation of 4-tert-butylphenylpropionaldehyde, can solve the problems of difficult control of the reaction process, large quality differences, and great environmental hazards, and achieve Increased reaction rate and selectivity, low production cost, and low environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of 4-tert-butylphenylpropionaldehyde, comprises the following steps:

[0028] Step 1, 0.0360g rhodium catalyst and 0.2953g phosphine ligand are added in the polytetrafluoroethylene liner of autoclave; Described rhodium catalyst is Rh(CO) 2 C 5 h 7 o 2 , the phosphine ligand is two (2,4-dicumylphenyl) pentaerythritol diphosphite; the molecular formula of the two (2,4-dicumylphenyl) pentaerythritol diphosphite is C 33 h 50 o 6 P 2 , the molecular weight is 604.7;

[0029] Step 2: Add 20mL of 4-tert-butylstyrene, 100mL of dimethylformamide and 0.1800g of an organic base compound to the polytetrafluoroethylene lining of the autoclave described in step 1, add the rotor to cover the lid of the reaction kettle, Nitrogen is passed through for leak detection, and after confirming that there is no leak, it is replaced three times with nitrogen and then three times with a mixture of hydrogen and carbon monoxide to...

Embodiment 2

[0035] The present embodiment provides a kind of preparation method of 4-tert-butylphenylpropionaldehyde, comprises the following steps:

[0036] Step 1, add 0.0272g rhodium catalyst and 0.2230g phosphine ligand in the polytetrafluoroethylene lining of autoclave; Described rhodium catalyst is Rh(CO) 2 C 5 h 7 o 2 , the phosphine ligand is bis(2,4-dicumylphenyl) pentaerythritol diphosphite;

[0037] Step 2: Add 20mL of 4-tert-butylstyrene, 100mL of dimethylformamide and 0.1361g of an organic base compound to the polytetrafluoroethylene lining of the autoclave described in step 1, add the rotor to cover the lid of the reaction kettle, Nitrogen is passed through for leak detection, and after confirming that there is no leak, it is replaced three times with nitrogen and then three times with a mixture of hydrogen and carbon monoxide to obtain a mixed system; the organic base compound is triethylamine; the mixture of hydrogen and carbon monoxide is The volume ratio of hydrogen ...

Embodiment 3

[0040] The present embodiment provides a kind of preparation method of 4-tert-butylphenylpropionaldehyde, comprises the following steps:

[0041] Step 1, 0.0272g rhodium catalyst and 0.1727g phosphine ligand are added in the polytetrafluoroethylene liner of autoclave; Described rhodium catalyst is Rh(CO) 2 C 5 h 7 o 2 , the phosphine ligand is diphenyl phosphite;

[0042]Step 2: Add 20mL of 4-tert-butylstyrene, 100mL of dimethylformamide and 0.1361g of an organic base compound to the polytetrafluoroethylene lining of the autoclave described in step 1, add the rotor to cover the lid of the reaction kettle, Nitrogen gas is passed through for leak detection, and after confirming that there is no gas leak, it is replaced three times with nitrogen gas and then replaced three times with a mixture of hydrogen and carbon monoxide to obtain a mixed system; the organic base compound is N,N-diisopropylethylamine; the The volume ratio of hydrogen and carbon monoxide in the mixture of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com