Chemical synthesis method for improving reaction rate and yield of bisphenol S monoallyl ether

A monoallyl ether, reaction rate technology, applied in the field of chemical synthesis, can solve the problems of slow reaction speed, large amount, waste alkali pollution, etc., to reduce the difficulty of refining, improve the specificity and rate of the reaction, and increase the yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

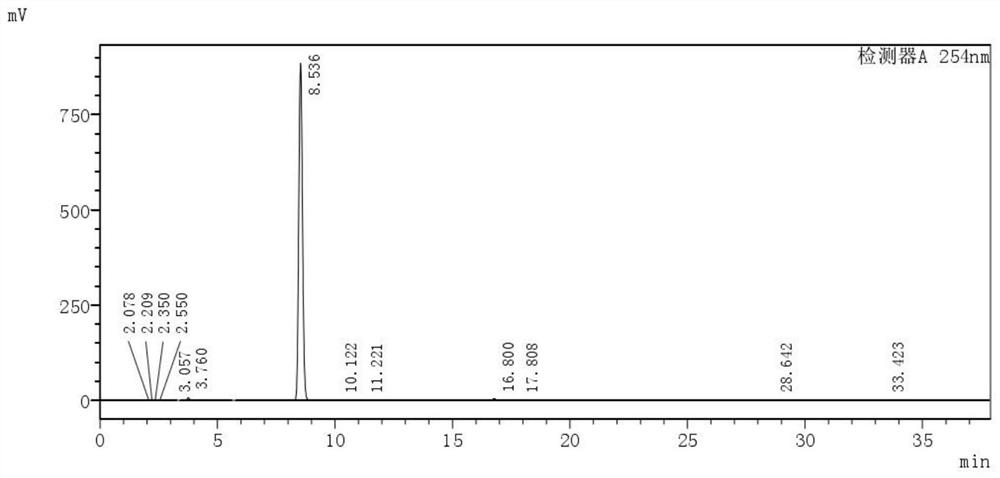

[0019] Such as Figure 1~4 Shown, a kind of chemical synthesis method that improves bisphenol S monoallyl ether reaction rate and yield may further comprise the steps:

[0020] Step (1). Add 500 grams of water, 1500 grams of organic solvent, 350-400 grams of BPS, 225-260 grams of liquid caustic soda and 5-10 grams of catalyst into the reaction flask in turn, and stir evenly;

[0021] Step (2). Add 145-165 grams of chloropropene, heat to 75-80 ° C, react for 2 hours, take a sample for detection, and the reaction ends;

[0022] Step (3). Slowly adjust the pH to 7 with hydrochloric acid;

[0023] Step (4). Lower the temperature to 25°C, stir and crystallize for 2 hours; obtain the crude product by suction filtration;

[0024] Step (5). The crude product is dissolved in 200-350ml of organic solvent and 200-350ml of water, heated to reflux to dissolve, cooled to 25°C, stirred and crystallized for 3 hours, suction filtered to obtain the finished product, and dried to obtain the pr...

Embodiment 1

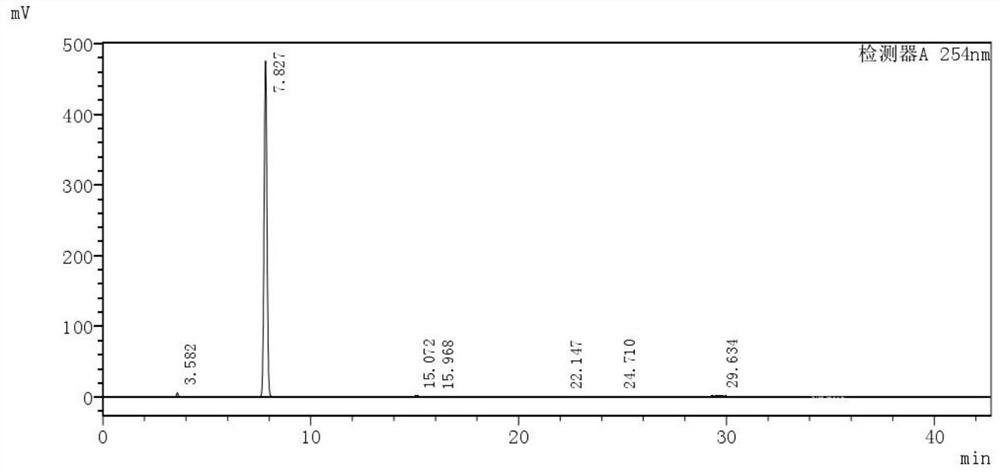

[0028] Implementation 1: Add 500 grams of water, 1,500 grams of organic solvent, 350 grams of BPS, 225 grams of liquid caustic soda and 5 grams of catalyst into the reaction flask in sequence, and stir evenly; add 145 grams of allyl chloride, heat to 80°C, react for 2 hours, and take samples for detection , the reaction is over; the pH is slowly adjusted to 7 with hydrochloric acid; the temperature is lowered to 25°C, stirred and crystallized for 2 hours; the crude product is obtained by suction filtration; the crude product is dissolved in 200ml of ethanol and 200ml of water, heated to reflux to dissolve, cooled to 25°C, stirred and crystallized for 2 hours Hour, suction filtration obtains finished product, obtains product 390 grams after oven dry; Calculate with BPS, molar yield 96.0%; Wherein catalyzer is tetrabutylammonium iodide and sodium iodide mass ratio (5~1): (1~5 ) mixture, see attached figure 1 .

Embodiment 2

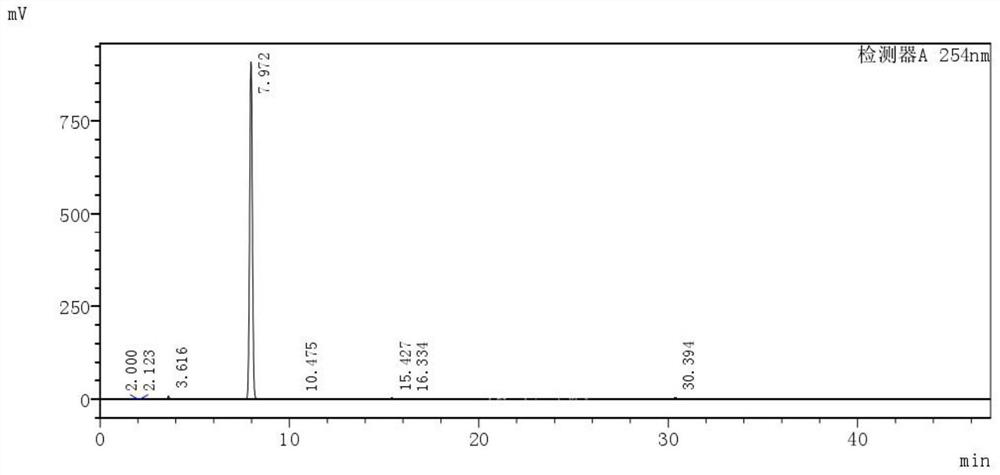

[0029] Implementation 2: Add 500 grams of water, 1500 grams of organic solvent, 350 grams of BPS, 225 grams of liquid caustic soda and 10 grams of catalyst into the reaction flask in sequence, and stir evenly; add 145 grams of chloropropene, heat to 79 ° C, react for 2 hours, and take samples for detection , the reaction is over; slowly adjust the pH to 7 with hydrochloric acid; cool down to 25°C, stir and crystallize for 2 hours; suction filter to obtain the crude product; dissolve the crude product in 200ml of isopropanol and 200ml of water, heat to reflux to dissolve, cool to 25°C, stir and crystallize After 2 hours, the finished product was obtained by suction filtration, and 388 grams of the product were obtained after drying; calculated by BPS, the molar yield was 95.6%. Wherein the catalyst is a mixture of tetrabutylammonium iodide and sodium iodide mass ratio (5-1): (1-5), the purity is detailed in the attached figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com