Method for resource utilization of phenolic tar

A technology for phenol tar and resource utilization, which is applied in the field of phenol tar resource utilization, can solve the problems of carcinogenicity, adverse effects on production safety and product quality, phenol toxicity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

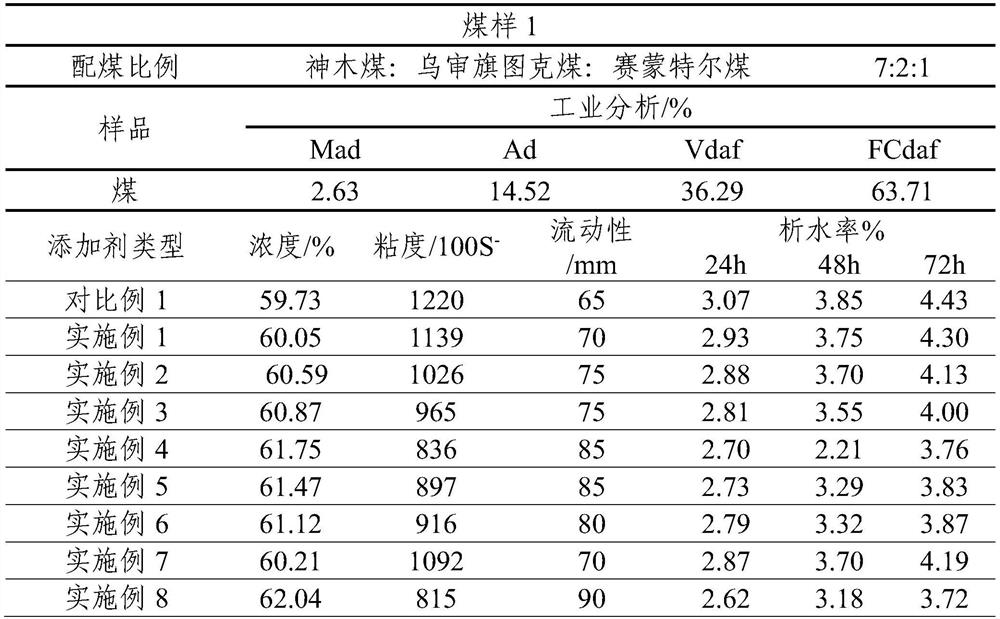

Embodiment 1

[0029] A method for resource utilization of phenol tar, raw materials are calculated in parts by mass, comprising the steps of:

[0030] (1) The first step of sulfonation: heat 50 parts of phenol tar to 100-110°C, slowly add 50 parts of concentrated sulfuric acid with a mass fraction of 98% dropwise, continue to keep warm for 1 hour after the addition is completed, and then use 32% sulfuric acid Liquid sodium hydroxide is neutralized to pH 7±0.5 to obtain the first step sulfonated compound.

[0031] (2) Second-step sulfonation: Add 133 parts of sodium sulfite with a purity of 90% and 210 parts of water to the first-step sulfonated product, heat, continue sulfonation and heat preservation reaction at 90-95°C for 1 hour, and obtain the second-step sulfonated product .

[0032] (3) Subsequent reaction: Add 210 parts of water to the second-step sulfonated compound, lower the temperature to below 50°C, start to slowly add 90 parts of acetone dropwise, and keep warm for 30 minutes ...

Embodiment 2

[0034] A method for resource utilization of phenol tar, raw materials are calculated in parts by mass, comprising the steps of:

[0035] (1) The first step of sulfonation: heat 50 parts of phenol tar to 100-110°C, slowly add 50 parts of concentrated sulfuric acid with a mass fraction of 98%, keep the temperature for 1 hour after the addition, and then use a liquid with a mass fraction of 32% Sodium hydroxide is neutralized to pH 7±0.5 to obtain the first step sulfonate.

[0036] (2) Second-step sulfonation: cool the first-step sulfonated compound to 60°C, add 133 parts of sodium sulfite with a purity of 90%, and 210 parts of water, heat, and continue the sulfonation reaction at 90-95°C for 1 hour to obtain the second step Two-step sulfonate.

[0037](3) Subsequent reaction: Add 210 parts of water to the sulfonated compound in the second step, lower the temperature to below 50°C, start to slowly add 90 parts of acetone dropwise, and keep the temperature for 30 minutes after th...

Embodiment 3

[0039] A method for resource utilization of phenol tar, raw materials are calculated in parts by mass, comprising the steps of:

[0040] (1) The first step of sulfonation: heat 50 parts of phenol tar to 100-110 ° C and slowly add 50 parts of oleum (105%) dropwise, keep warm for 1 hour after the addition, and then oxidize with liquid hydroxide with a mass fraction of 32% Sodium is neutralized to pH 7±0.5 to obtain the first step sulfonate.

[0041] (2) Second-step sulfonation: cool the first-step sulfonated compound to 60°C, add 133 parts of sodium sulfite with a purity of 90%, and 210 parts of water, heat, and continue the sulfonation reaction at 85-90°C for 1.5 hours to obtain The second step sulfonate.

[0042] (3) Subsequent reaction: Add 210 parts of water to the sulfonated compound in the second step, lower the temperature to below 50°C, start to slowly add 90 parts of acetone dropwise, and keep the temperature for 30 minutes after the dropwise addition. After the heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper mouth diameter | aaaaa | aaaaa |

| Lower mouth diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com