Preparation method and preparation device of semi-aromatic polyamide

A semi-aromatic polyamide and lactam technology, applied in feeding devices, chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, etc., can solve the problem of gel particles losing melt processability, semi-aromatic Deterioration of polyamide resin performance, degradation and crosslinking of nylon resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1: PA6T / 6I / 66=65:25:10

[0082] (1) In the 50L salt forming kettle, add 4.648kg hexamethylenediamine, 0.5846kg adipic acid, 4.319kg terephthalic acid, 1.661kg isophthalic acid, 20g sodium hypophosphite and 16.82kg deionized water, the mixture is in Stir at 80°C to form a salt for 30 minutes to obtain a salt solution.

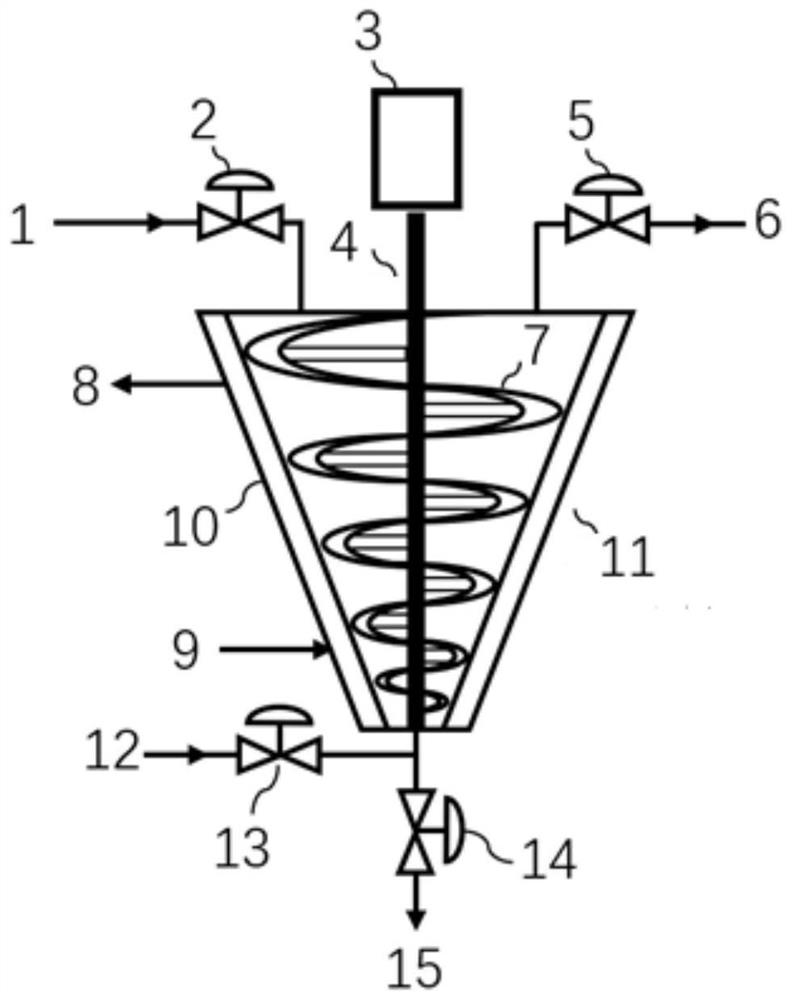

[0083] (2) After the salt is formed, the salt solution is added to the conical high-pressure polymerization kettle for polymerization reaction. The reaction temperature is 250° C. and the pressure is 3.5 MPa; after the salt solution is added to the reactor, close the reactor feed valve, The gas in the kettle was replaced by nitrogen, and the temperature in the kettle was raised to 250° C. within 85 minutes, and the pressure in the kettle reached 3.5 MPa. The stirring state was kept during the whole heating process, and the stirring rate was 5 r / min.

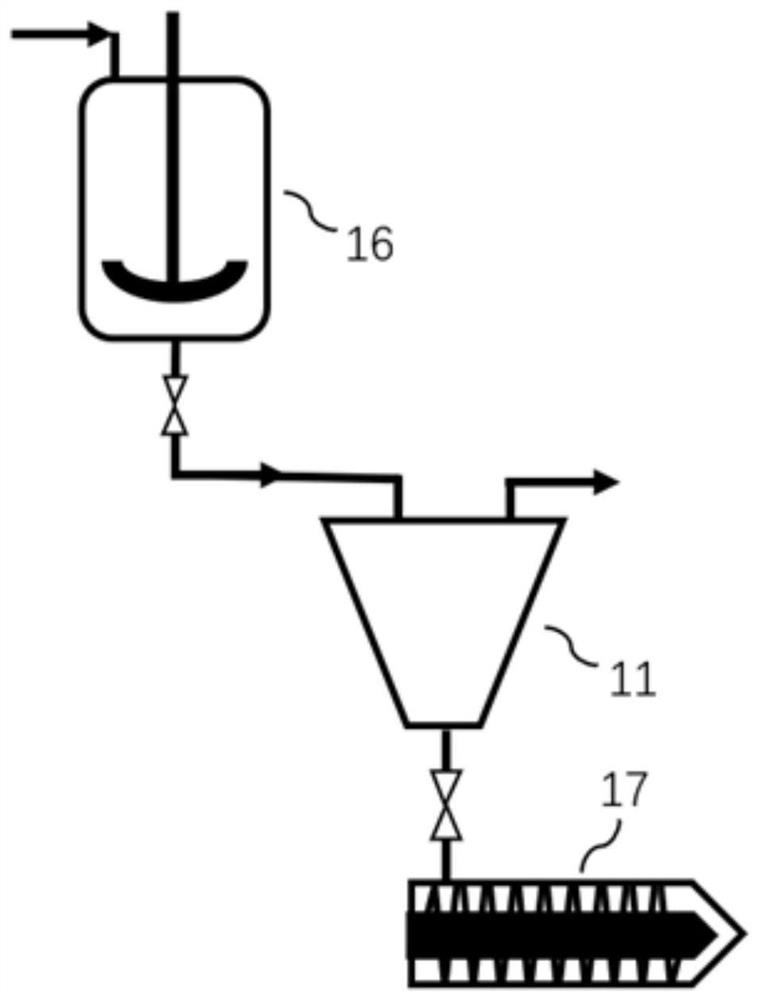

[0084] (3) After the polymerization reaction is over, the pressure in the kettle is gradually re...

Embodiment 2

[0086] Embodiment 2: PA6T / 6I / 66=60:15:25

[0087] (1) In the 50L salt forming kettle, add 4.648kg hexamethylenediamine, 1.461kg adipic acid, 3.987kg terephthalic acid, 0.9968kg isophthalic acid, 20g sodium hypophosphite and 16.64kg deionized water, the mixture is in Stir at 80°C to form a salt for 30 minutes to obtain a salt solution.

[0088] (2) After the salt is formed, the salt solution is added to the conical high-pressure polymerization kettle for polymerization reaction. The reaction temperature is 230°C and the pressure is 2.5MPa; the effective volume of the polymerization kettle is 100L, the height of the reaction kettle is 1800mm, and the polymerization kettle is equipped with The jacket is used to heat the polymerization kettle through heat-conducting oil. The reactor is equipped with a ribbon-type stirring paddle with a width of 82 mm. After the salt solution is added to the reactor, the feed valve of the reactor is closed, and the gas in the reactor is replaced by...

Embodiment 3

[0091] Embodiment 3: PA6T / 6I=65:35

[0092] (1) Add 4.648kg of hexamethylenediamine, 4.319kg of terephthalic acid, 2.326kg of isophthalic acid, 20g of sodium hypophosphite and 16.94kg of deionized water into a 50L salt-forming kettle, and stir the mixture at 80°C to form a salt 30min to obtain a saline solution.

[0093] (2) After the salt is formed, the salt solution is added to the conical high-pressure polymerization kettle for polymerization reaction. The reaction temperature is 250°C and the pressure is 3.5MPa; the effective volume of the polymerization kettle is 100L, the height of the reaction kettle is 1800mm, and the polymerization kettle is equipped with The jacket is used to heat the polymerization kettle through heat-conducting oil. The reactor is equipped with a ribbon-type stirring paddle with a width of 82 mm. After the salt solution is added to the reactor, the feed valve of the reactor is closed, and the gas in the reactor is replaced by nitrogen. The tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com