High-hardness cobalt-based metal glass and preparation method thereof

A base metal, high hardness technology, applied in the field of cobalt-based amorphous structural materials, can solve problems such as poor vitrification forming ability, and achieve the effects of improved hardness value, superior comprehensive performance, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] prepared by the single-roll stripping method (Co 0.75 Cr 0.125 Mo 0.125 ) 75 B 25 , (Co 0.75 Cr 0.125 Mo 0.125 ) 73 B 27 , (Co 0.75 Cr 0.125 Mo 0.125 ) 71 B 29 , (Co 0.75 Cr 0.125 Mo 0.125 ) 69 B 31 Amorphous alloy strips, the specific steps are as follows:

[0037] (1) Convert the atomic percentage in the alloy expression to mass percentage for batching. Firstly, all kinds of high-purity metals and metalloids (purity not less than 99.9wt%) required are placed in alcohol, and ultrasonically cleaned in an ultrasonic cleaning machine. Then take by weighing Co, Mo, Cr, B raw material of corresponding quality stand-by;

[0038] (2) Place the weighed raw materials of corresponding quality in the crucible of the vacuum arc melting furnace, and when the vacuum reaches 2.5×10-3Pa, fill in argon as a protective atmosphere, and fill the protective gas until the pressure in the melting furnace is -0.5Pa. Heating with an electric arc until the alloy is complet...

Embodiment 2

[0041] Prepared by spray casting (Co 0.75 Cr 0.125 Mo 0.125 ) 75 B 25 , (Co 0.75 Cr 0.125 Mo 0.125 ) 73 B 27 , (Co 0.75 Cr 0.125 Mo 0.125 ) 71 B 29 , (Co 0.75 Cr 0.125 Mo 0.125 ) 69 B 31 Amorphous alloy rods, the specific steps are as follows:

[0042] (1) Convert the atomic percentage in the alloy expression to mass percentage for batching. Firstly, all kinds of high-purity metals and metalloids (purity not less than 99.9wt%) required are placed in alcohol, and ultrasonically cleaned in an ultrasonic cleaning machine. Then take by weighing Co, Mo, Cr, B raw material of corresponding quality stand-by;

[0043] (2) Place the weighed raw materials of corresponding quality in the crucible of the vacuum arc melting furnace, and when the vacuum reaches 2.5×10-3Pa, fill in argon as a protective atmosphere, and fill the protective gas until the pressure in the melting furnace is -0.5Pa. Heating with an electric arc until the alloy is completely melted into a uni...

Embodiment 3

[0046] Sample characterization experiment: The prepared amorphous alloy strips and rods are subjected to a series of tests to determine whether the samples are amorphous alloys. The details are as follows,

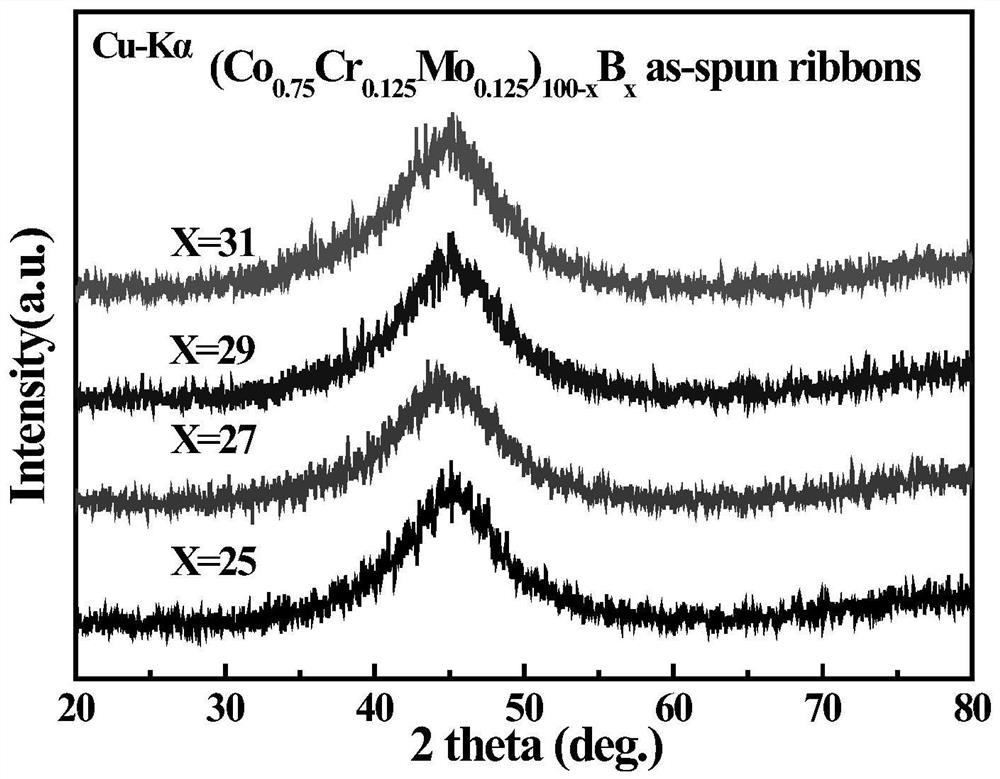

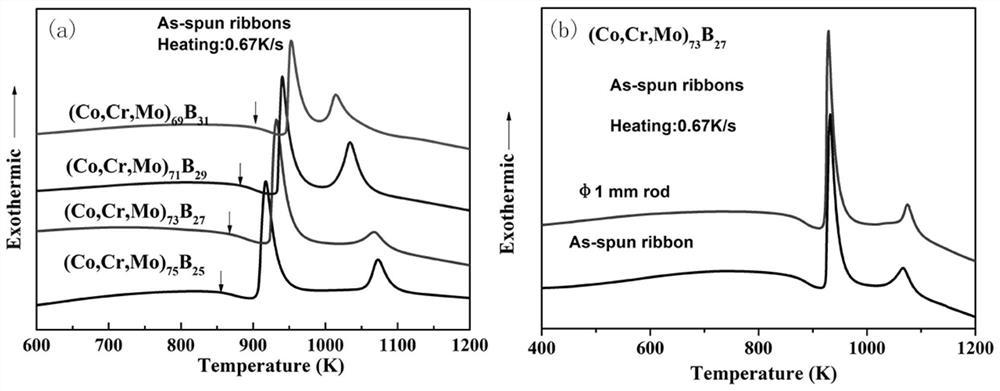

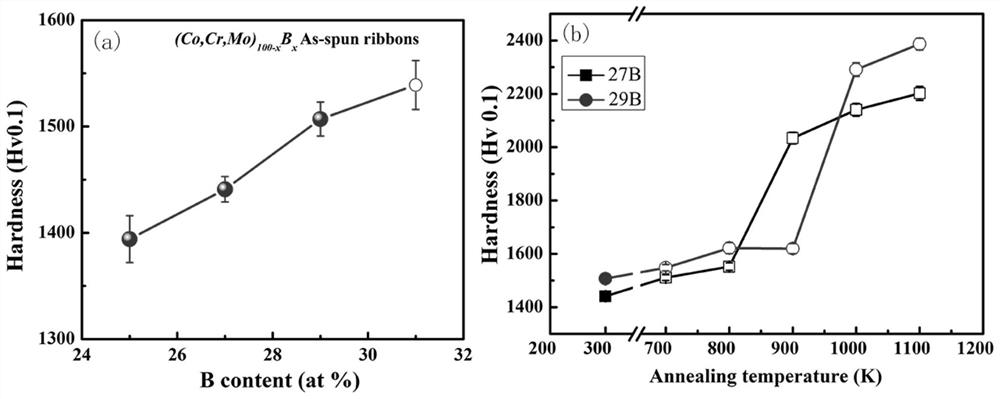

[0047] (1) Amorphous structure characterization: For alloy strip samples, cut 3-5 strips with a length of about 1 cm, and fix them on the single crystal silicon sample stage with double-sided adhesive with the free surface upward. For bar experiments, First use a metallographic cutting machine to cut out a metal with a thickness of 2mm, polish the cross-section of the bar with No. 2000 water sandpaper, and then clean it with alcohol. Place the polished side up on the single crystal silicon sample stage. The structure of the sample was detected by X-ray diffractometer (XRD), and the XRD diffraction peak was a single diffuse steamed bread peak. figure 1 It is a strip sample XRD, which shows a broad diffraction peak, and there is no obvious crystal precipitation peak. (Co ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com