Samarium-iron-cobalt film electroplating liquid and preparation method thereof

An electroplating solution, samarium-iron technology, applied in the field of samarium-iron-cobalt thin-film electroplating solution and its preparation, can solve problems such as difficult binary co-deposition and inability to realize co-deposition of Sm-Fe-Co ternary alloy, achieving a breakthrough technology Bottleneck, controllable electrochemical co-deposition, effect of uniform element distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

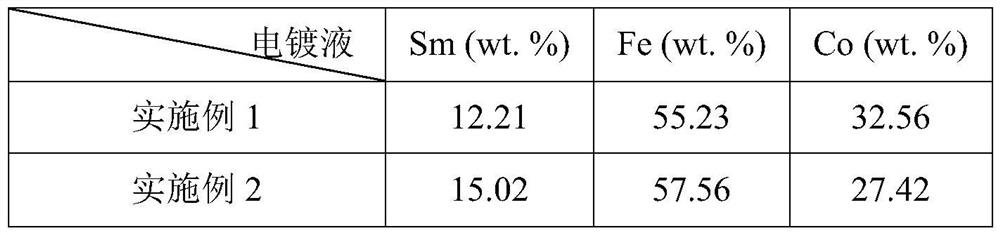

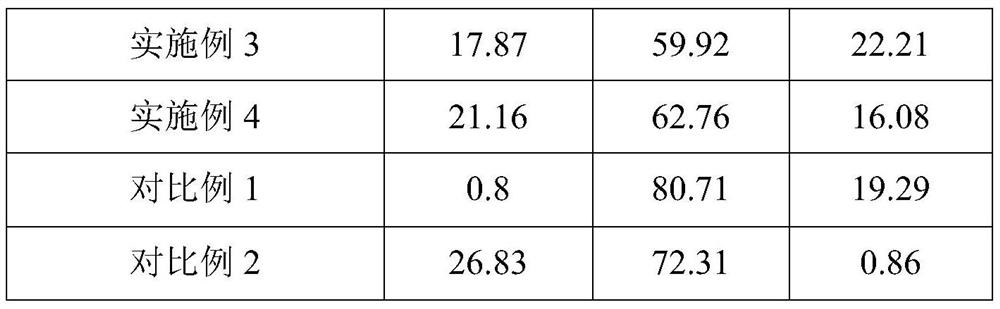

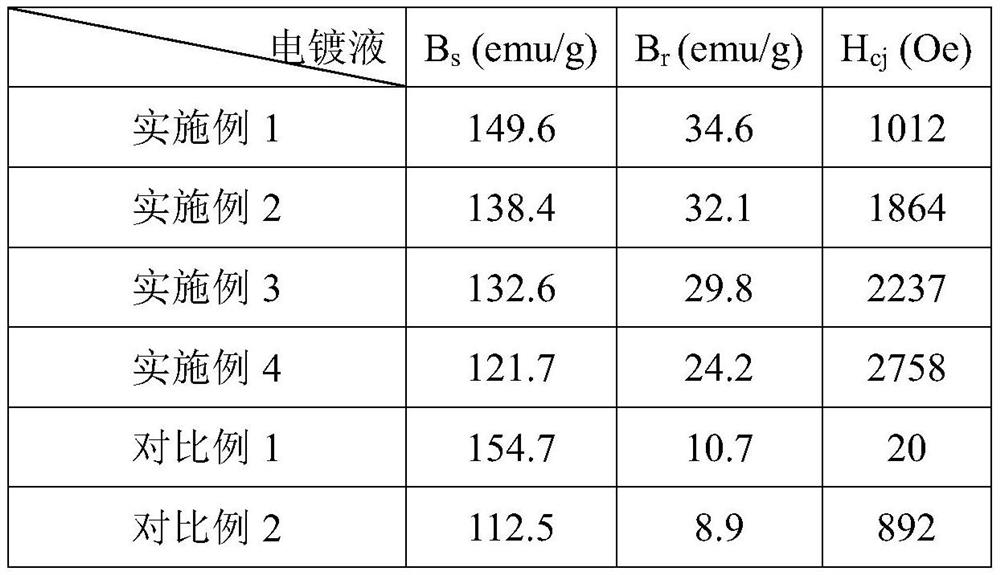

Embodiment 1

[0025] A preparation method of a novel samarium-iron-cobalt thin film electroplating solution, comprising the following steps:

[0026] Add 3g of boric acid, 3g of sodium citrate, 2g of glacial acetic acid, 10g of complexing agent (including 3g of sulfamic acid and 7g of glycine) and 1g of potassium nitrate into deionized water at 40°C. Adjust the pH to 1.0, add 5g of cobalt chloride, 10g of samarium chloride, 5g of ferrous chloride, and 7g of ferric chloride to the mixed solution, stir and dissolve, then add the remaining amount of deionized water to a total volume of 1L, and add hydroxide Sodium adjusts the pH of the solution to 3.0 to obtain a new type of samarium-iron-cobalt thin film electroplating solution.

Embodiment 2

[0028] A preparation method of a novel samarium-iron-cobalt thin film electroplating solution, comprising the following steps:

[0029] Add 4g of boric acid, 4g of sodium citrate, 3g of glacial acetic acid, 15g of complexing agent (7g of sulfamic acid, 8g of glycine), and 1g of potassium nitrate into deionized water at 45°C, stir well and dissolve to form a mixed solution, adjust the pH with HCl 1.5, add 10g of cobalt chloride, 15g of samarium chloride, 10g of ferrous chloride, and 20g of ferric chloride to the mixed solution, stir and dissolve, then add the remaining amount of deionized water to a total volume of 1L, add sodium hydroxide to adjust The pH of the solution is 2.5, and a novel samarium-iron-cobalt thin film electroplating solution is obtained.

Embodiment 3

[0031] A preparation method of a novel samarium-iron-cobalt thin film electroplating solution, comprising the following steps:

[0032] Add 5g of boric acid, 3g of sodium citrate, 5g of glacial acetic acid, 25g of complexing agent (10g of sulfamic acid, 15g of glycine), and 2g of potassium nitrate into deionized water at 50°C, stir well and dissolve to form a mixed solution, adjust the pH with HCl 3.0, add 10g of cobalt chloride, 15g of samarium chloride, 8g of ferrous chloride, and 20g of ferric chloride to the mixed solution and stir to dissolve, then add the remaining amount of deionized water to a total volume of 1L, add sodium hydroxide to adjust The pH of the solution is 3.5, and a novel samarium-iron-cobalt thin film electroplating solution is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com