Horizontal in-hole type high-power shock wave generating device and method

A technology for generating devices and shock waves, which is applied to drilling equipment and methods, earthwork drilling, and discharge machinery, etc., to achieve the effects of reducing operating costs, reducing labor intensity, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings. The examples are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

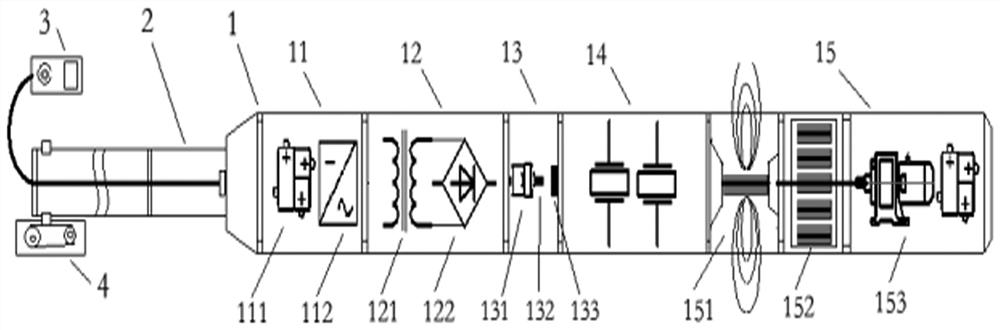

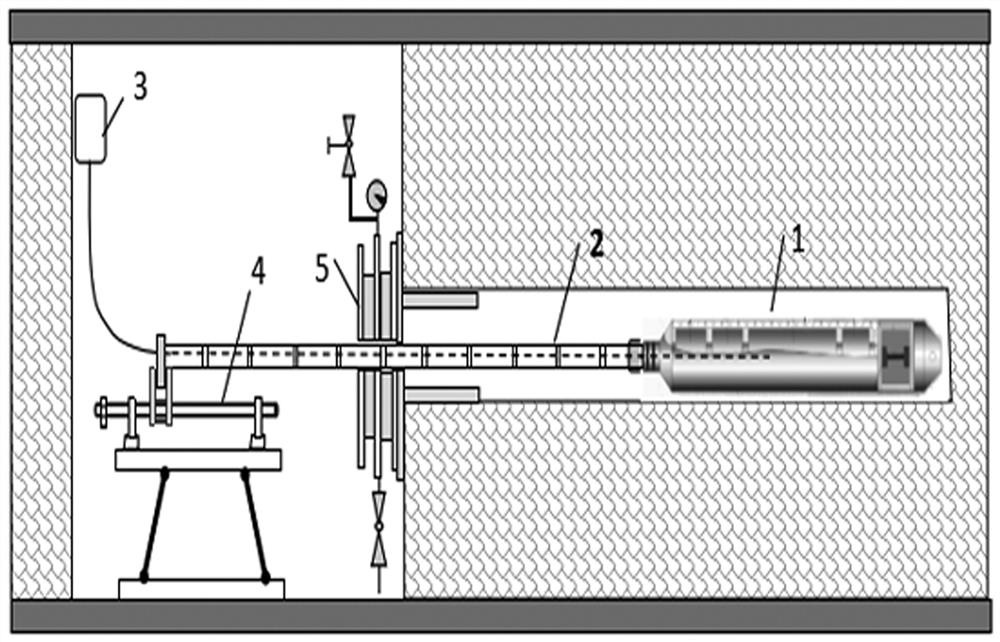

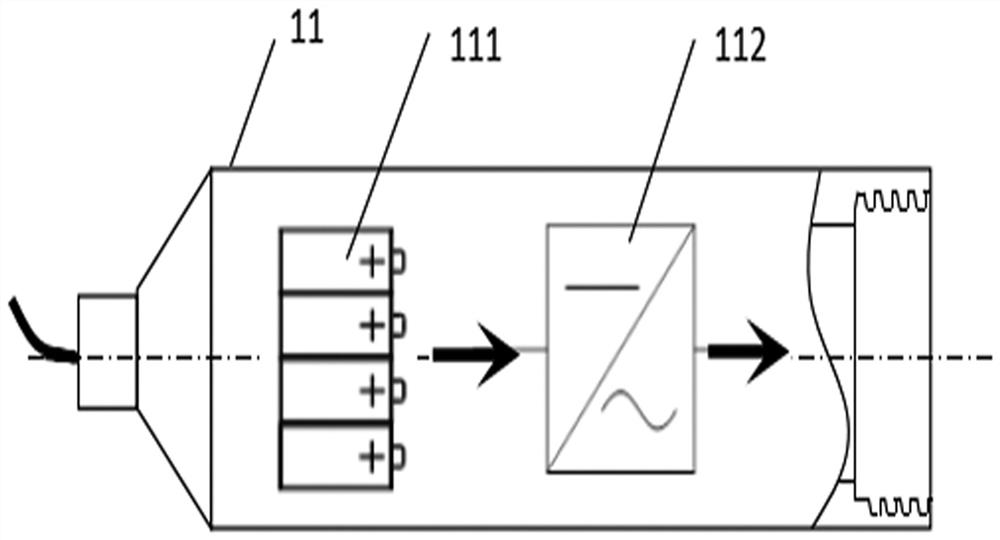

[0039] like Figures 1 to 7 A horizontal hole type high-power shock wave generating device is shown, including a blocker 5 acting on the gas orifice, a propulsion mechanism 4, a controller 3, a shock wave generator 1 and a number of hollow cable steel pipes 2, the The occluder 5 includes a flange, a water injection hole, a pressure gauge, and a valve, wherein the shock wave generator 1 is composed of a low-voltage power supply 11, a DC high-voltage power supply 12, a controllable gas switch 13, an energy storage capacitor 14, and an energy converter 15. One end of the power source 11 and the energy converter 15 is provided with a threaded structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com