Coal chemical-looping gasification process design method based on multi-scale modeling and application thereof

A technology of process design and chemical chain, applied in the direction of design optimization/simulation, computer-aided design, special data processing applications, etc., can solve problems such as simulation, inability to conduct dynamic research, and inability to meet the requirements of industrial synthesis gas production, so as to meet the requirements of production required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A clean production process design of coal chemical looping gasification based on multi-scale modeling and control, the establishment of the CP-CLG system, the specific steps are as follows:

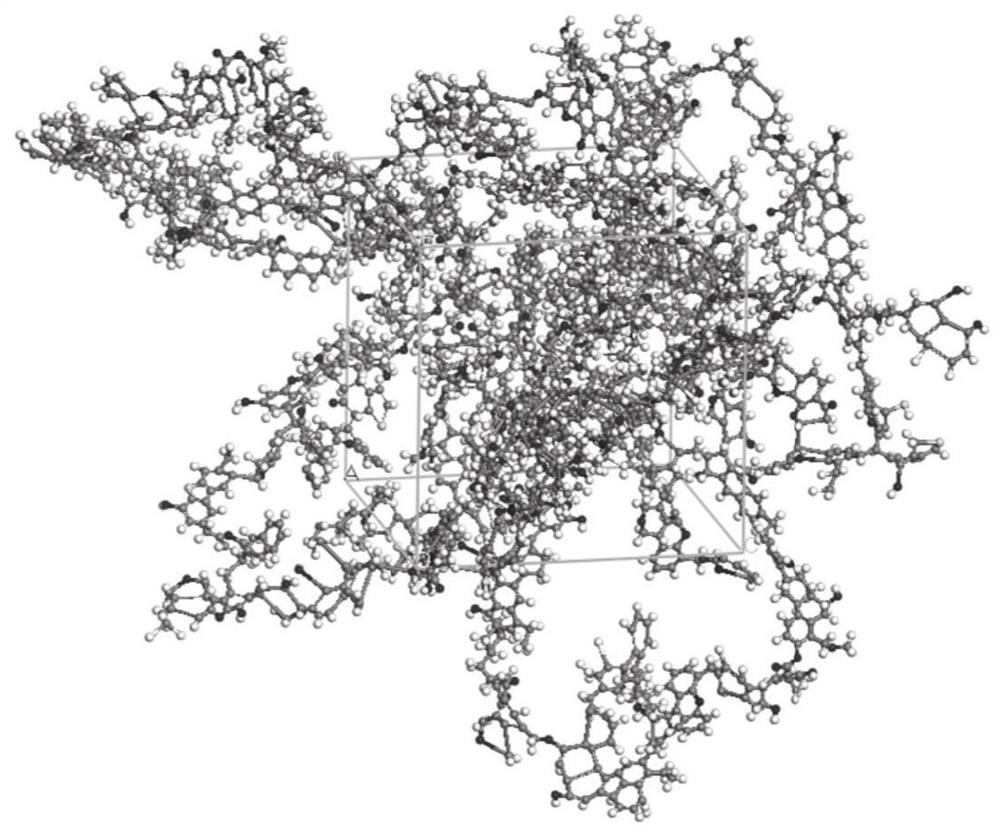

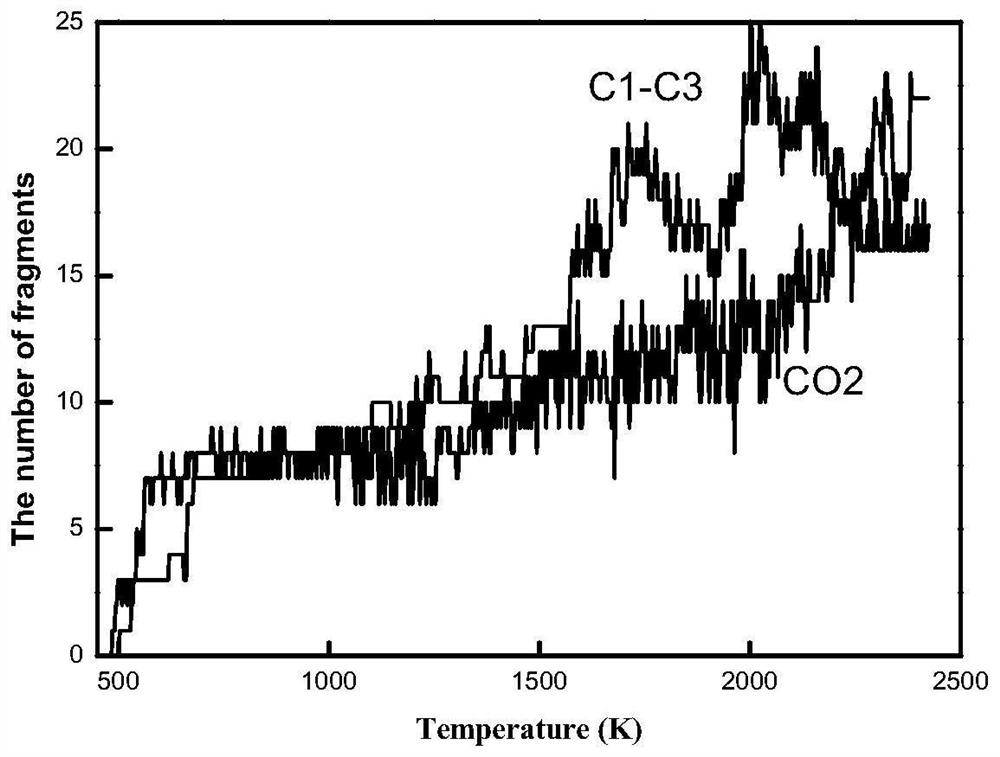

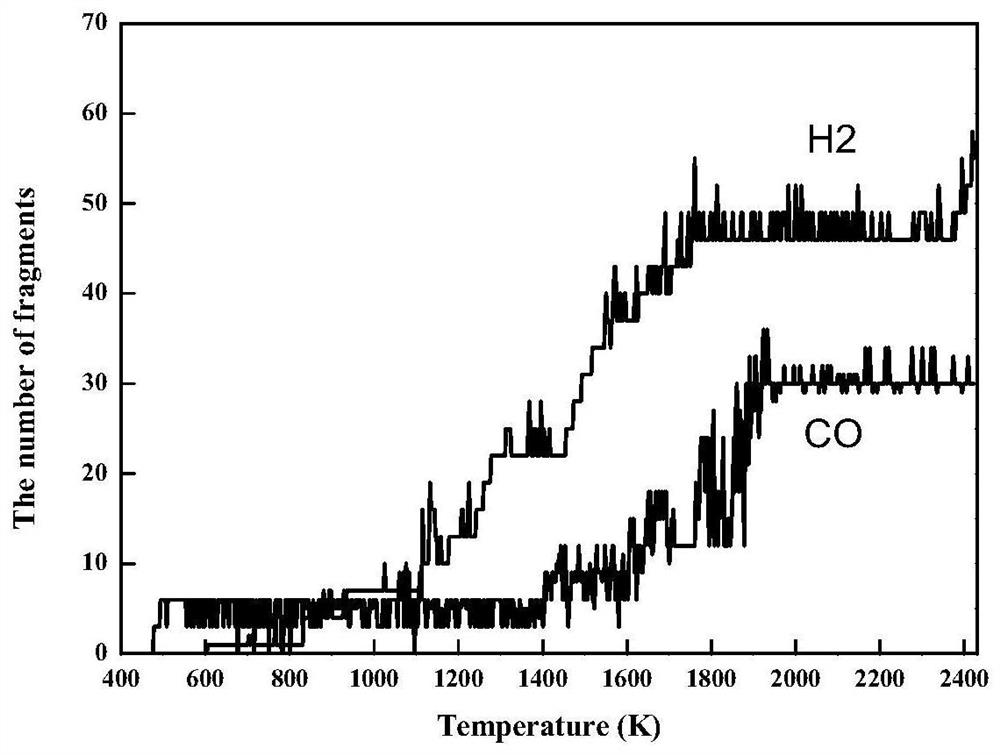

[0063] (1) The coal model was established and the global energy optimization was carried out, and the mechanism of CP was analyzed by ReaxFF-MD simulation, and the optimal CP temperature was obtained by analyzing the number of fragments.

[0064] Firstly, the structural unit of coal is established to represent the molecular skeleton. The coal molecular building blocks are then hydrogenated with tunable hydrogen to obtain a reasonable initial configuration. Finally, with the energy as the objective function, molecular mechanics simulation was performed on the initial configuration to optimize its geometric structure. The specific parameters are as follows: the task type is geometric optimization, the optimization quality is medium, and the energy optimization method is intelligent....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com