Application of sialic acid salt oil suspension in preparation of capsules

A sialic acid salt and sialic acid technology, applied in the application, capsule delivery, food forming and other directions, can solve the problems of affecting the appearance and shape of the capsule, the disintegration time limit of the dissolution rate, the product quality not meeting the requirements, and the small stimulation effect on the human body. , to avoid whitening appearance, easy storage, high sialic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

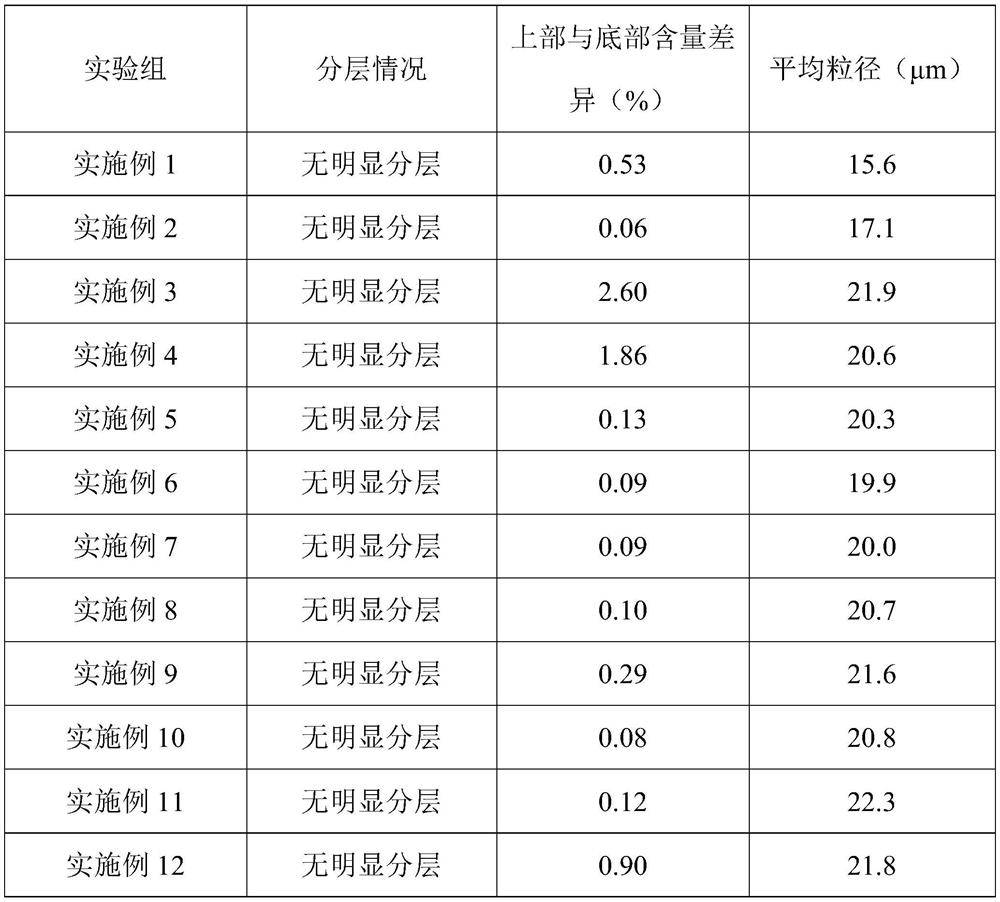

Embodiment 1

[0087] The present embodiment prepares sialate oil suspension, and described sialate oil suspension is sodium sialate 20% and docosahexaenoic acid grease (DHA grease) 80% by mass percentage, and its preparation method comprises the following steps :

[0088] (1) dissolving sialic acid in water, under high shear, adding sodium bicarbonate in molar mass ratio, reacting, forming sodium sialate solution, and adjusting the pH of sodium sialate solution to be 7;

[0089] (2) The sodium sialate solution is spray-dried under the conditions of an inlet air temperature of 210°C, a material temperature of 70°C, an outlet air temperature of 40°C, and a feed rate of 100L / h, followed by crushing to obtain the particle size Sodium sialate ≤100μm;

[0090] (3) Under 10000rpm shearing, sodium sialate is added to the DHA oil in proportion, sheared for 30min, and homogenized 3 times using a homogenizer (secondary pressure 8bar, primary pressure 1000bar) to obtain sialic acid Sodium Oil Suspens...

Embodiment 2

[0092] The present embodiment prepares sialate oil suspension, and described sialate oil suspension is sodium sialate 20%, phospholipid 0.5% and DHA grease 79.5% by mass percentage, and its preparation method comprises the steps:

[0093] (1) dissolving sialic acid in water, under high shear, adding sodium bicarbonate in molar mass ratio, reacting, forming sodium sialate solution, and adjusting the pH of sodium sialate solution to be 7;

[0094] (2) The sodium sialate solution is spray-dried under the conditions of an inlet air temperature of 210°C, a material temperature of 70°C, an outlet air temperature of 40°C, and a feed rate of 100L / h, followed by crushing to obtain the particle size Sodium sialate ≤100μm;

[0095] (3) Under 10000rpm shearing, sodium sialate and phospholipids are added in proportion to DHA oil, sheared for 30min, and homogenized 3 times using a homogenizer (secondary pressure 8bar, primary pressure 1000bar), to obtain Sodium sialate oil suspension.

Embodiment 3

[0097] The present embodiment prepares sialate oil suspension, and described sialate oil suspension is sodium sialate 40% and dihigh-γ-linolenic acid oil 60% by mass percentage, and its preparation method comprises the steps:

[0098] (1) dissolving sialic acid in water, under high shear, adding sodium bicarbonate in molar mass ratio, reacting, forming sodium sialate solution, and adjusting the pH of sodium sialate solution to be 7;

[0099] (2) The sodium sialate solution is spray-dried under the conditions of an inlet air temperature of 210°C, a material temperature of 70°C, an outlet air temperature of 40°C, and a feed rate of 100L / h, followed by crushing to obtain the particle size Sodium sialate ≤100μm;

[0100] (3) Under 8000rpm shearing, sodium sialate is added in proportion to two high-γ-linolenic acid oils, sheared for 35min, and homogenized 4 times using a homogenizer (secondary pressure 8bar, primary pressure 700bar), obtaining sodium sialate oil suspension.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com