Biomass-based porous carbon material, preparation method and application of biomass-based porous carbon material in separation of 1, 3-butadiene from C4 olefin mixture

A technology of porous carbon materials and biomass carbon sources, applied in the direction of carbon compounds, filtration separation, separation methods, etc., can solve the problems of production cost, adsorption capacity and dynamic separation performance that have not been completely resolved, and achieve low equipment investment, Good industrial application prospect, high selective separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 6g cornstarch, 0.66g acrylic acid to 60mL distilled water and mix. After uniform dispersion, it was transferred to an autoclave for hydrothermal polymerization at 190° C. for 14 hours, and the obtained carbon precursor was vacuum filtered and washed with water. Then, the carbon precursor was added and mixed with 0.16mol / L NaOH solution, stirred and reacted at 60°C for 12h, then the mixture was washed and dried, placed in a porcelain boat, placed in a high-temperature tube furnace, and raised under nitrogen protection. After reaching 800°C, the activation reaction was carried out for 1.5 h, after cooling, it was acid-washed with 1 mol / L dilute hydrochloric acid and washed with distilled water to neutrality, and a biomass-based porous carbon material was obtained after drying.

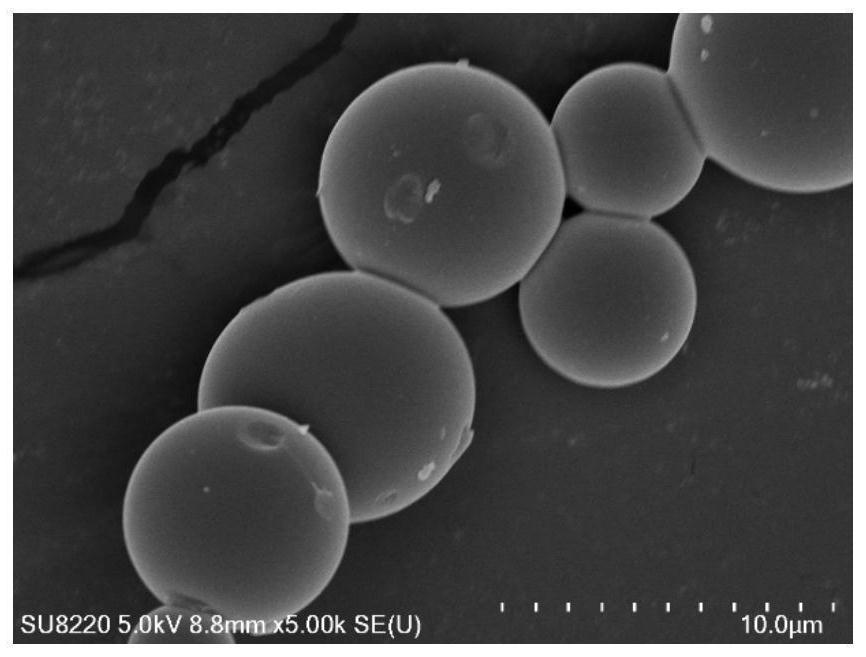

[0032] The scanning electron microscope picture of the material prepared in this example is as follows figure 1 As shown, after high-temperature carbonization activation, it still has a unifo...

Embodiment 2

[0035] Add 6g cornstarch, 0.66g acrylic acid to 60mL distilled water and mix. After uniform dispersion, it was transferred to an autoclave for hydrothermal polymerization at 190° C. for 14 hours, and the obtained carbon precursor was vacuum filtered and washed with water. Then, the carbon precursor was added and mixed with 0.16mol / L KOH solution, stirred and reacted at 60°C for 10h, then the mixture was washed and dried, then placed in a porcelain boat, placed in a high-temperature tube furnace, and raised under the protection of nitrogen. After reaching 800°C, the activation reaction was carried out for 1.5 h, after cooling, it was acid-washed with 1 mol / L dilute hydrochloric acid and washed with distilled water to neutrality, and a biomass-based porous carbon material was obtained after drying.

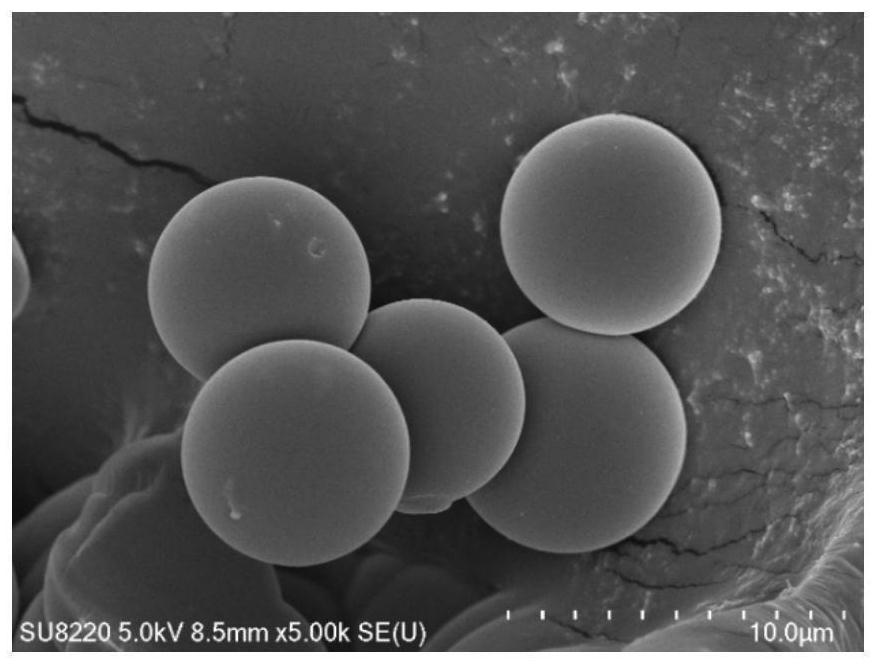

[0036] The scanning electron microscope picture of the material prepared in this example is as follows image 3 As shown, after high-temperature carbonization activation, it still ...

Embodiment 3

[0039] 6g of potato starch and 0.66g of acrylic acid were added to 60mL of distilled water for mixing. After uniform dispersion, it was transferred to an autoclave for hydrothermal polymerization at 190° C. for 14 hours, and the obtained carbon precursor was vacuum filtered and washed with water. Then, the carbon precursor was added and mixed with 0.16mol / L KOH solution, stirred and reacted at 60°C for 10h, then the mixture was washed and dried, then placed in a porcelain boat, placed in a high-temperature tube furnace, and raised under the protection of nitrogen. After reaching 800°C, the activation reaction was carried out for 1.5 h, after cooling, it was acid-washed with 1 mol / L dilute hydrochloric acid and washed with distilled water to neutrality, and a biomass-based porous carbon material was obtained after drying.

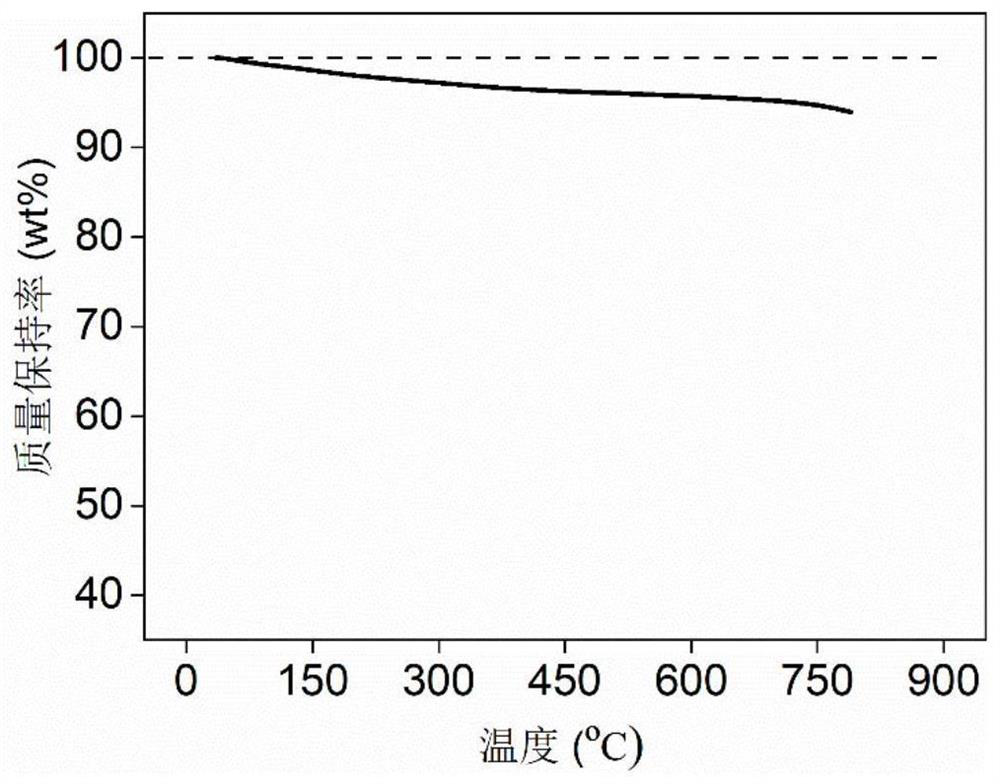

[0040] The adsorption isotherm of the material prepared in this example to the carbon tetraolefin component at 298K is as follows Figure 4 As shown, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com