A method for converting carbon tetraolefins to propylene by catalytic cracking or cracking process

A technology of catalytic cracking and carbon tetraolefins, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of large solvent ratio, large reflux ratio, and low butene yield, and achieve Improve selectivity and yield, increase device capacity, and fully utilize resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

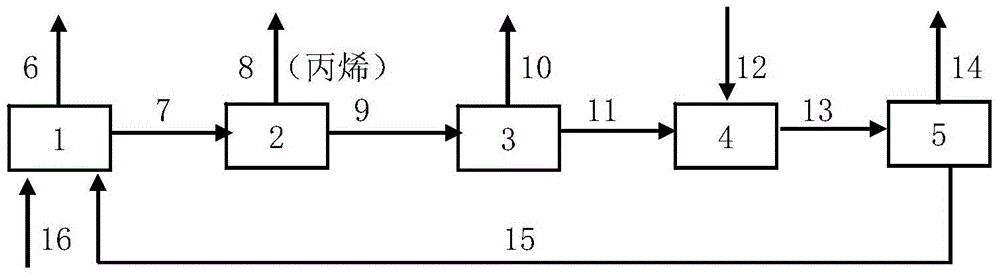

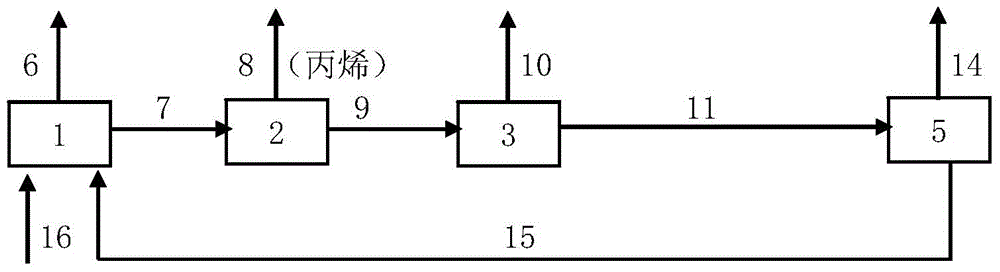

[0041] The fixed-bed catalytic reactor ( figure 1 Middle module 4), heated to 120°C. Water (stream 12) and the mixture containing butane and butene-1 (stream 11) according to water / ene molar ratio 1:1, mass space velocity is 3h -1 , into the hydration reactor ( figure 1 Middle module 4), contact with the hydration reaction catalyst to carry out the hydration reaction, the temperature is 120° C., the outlet of the hydration reactor obtains the mixture of hydrated sec-butanol and butane (stream 13). The liquid product obtained at the outlet of the hydration reactor is subjected to rectification separation (module 5), unreacted butane (stream 14) is obtained at the top of the tower, and sec-butanol (stream 15) is obtained at the bottom of the tower. This stream (stream 15) is introduced into a riser catalytic cracking reaction device (module 1) containing H-ZSM-5 molecular sieve catalyst, and at a reaction temperature of 540° C., a cracking reaction occurs simultaneously with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com