Green and environment-friendly interior wall putty powder and preparation method thereof

An interior wall putty powder, green and environmentally friendly technology, applied in the direction of filling slurry, etc., can solve the problems of short construction period, poor water resistance, large loss of strength of a single retarder, etc., and achieve high production efficiency and finished product pass rate, mechanical mechanics Good performance and water resistance, excellent film-forming properties and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

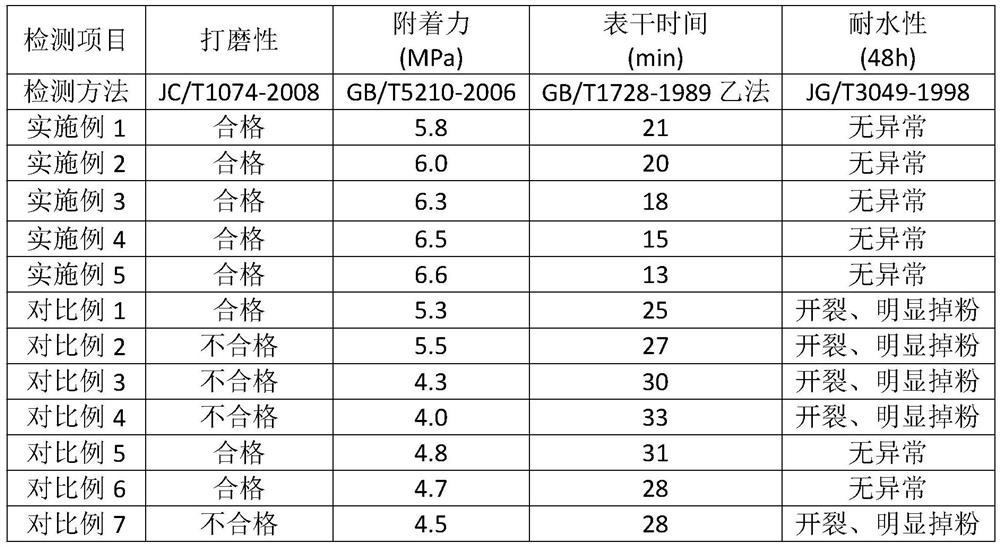

Examples

Embodiment 1

[0026] A green and environment-friendly interior wall putty powder, comprising the following components by weight: 50 parts of Shuangfei powder, 8 parts of white volcanic ash, 5 parts of attapulgite, 2 parts of white graphene nanofiber, single-ended amino polyethylene glycol modified 4 parts of rosin-based hyperbranched polyester, 2 parts of rosin-based monoquaternary ammonium trimethylsilicate tetrakis (1-imidazolyl) borate compound salt, 0.5 part of mastic gum.

[0027] The particle size of the Shuangfei powder is 300 mesh; the particle size of the white volcanic ash is 500 mesh; the particle size of the attapulgite is 1000 mesh.

[0028] The preparation method of the single-ended amino polyethylene glycol modified rosin-based hyperbranched polyester comprises the following steps: after adding the single-ended amino polyethylene glycol and the rosin-based hyperbranched polyester to an organic solvent, then adding 2-Ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline was reacted und...

Embodiment 2

[0032] A green environment-friendly interior wall putty powder, comprising the following components by weight: 53 parts of Shuangfei powder, 10 parts of white volcanic ash, 6 parts of attapulgite, 2.2 parts of white graphene nanofibers, single-ended amino polyethylene glycol modified 5 parts of rosin-based hyperbranched polyester, 2.5 parts of rosin-based monoquaternary ammonium trimethylsilicate tetrakis (1-imidazolyl) borate compound salt, and 0.7 parts of mastic gum.

[0033] The particle size of the Shuangfei powder is 350 mesh; the particle size of the white volcanic ash is 600 mesh; the particle size of the attapulgite is 1050 mesh.

[0034] The preparation method of the single-ended amino polyethylene glycol modified rosin-based hyperbranched polyester comprises the following steps: after adding the single-ended amino polyethylene glycol and the rosin-based hyperbranched polyester to an organic solvent, then adding 2-Ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline was reac...

Embodiment 3

[0038] A green environment-friendly interior wall putty powder, comprising the following components by weight: 55 parts of Shuangfei powder, 13 parts of white volcanic ash, 7.5 parts of attapulgite, 2.5 parts of white graphene nanofiber, single-ended amino polyethylene glycol modified 5.5 parts of rosin-based hyperbranched polyester, 3 parts of rosin-based monoquaternary ammonium trimethylsilicate tetrakis (1-imidazolyl) borate compound salt, and 1 part of mastic gum.

[0039] The particle size of the Shuangfei powder is 400 mesh; the particle size of the white volcanic ash is 650 mesh; the particle size of the attapulgite is 1100 mesh.

[0040] The preparation method of the single-ended amino polyethylene glycol modified rosin-based hyperbranched polyester comprises the following steps: after adding the single-ended amino polyethylene glycol and the rosin-based hyperbranched polyester to an organic solvent, then adding 2-Ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline was reacte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com