High-performance coating for metal film resistor and preparation method of coating

A metal film resistor, high-performance technology, used in epoxy resin coatings, coatings, etc., can solve the problems of less research on water absorption of coatings and high water absorption of coatings, and achieve high thermal conductivity, strong surface area, and improved power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

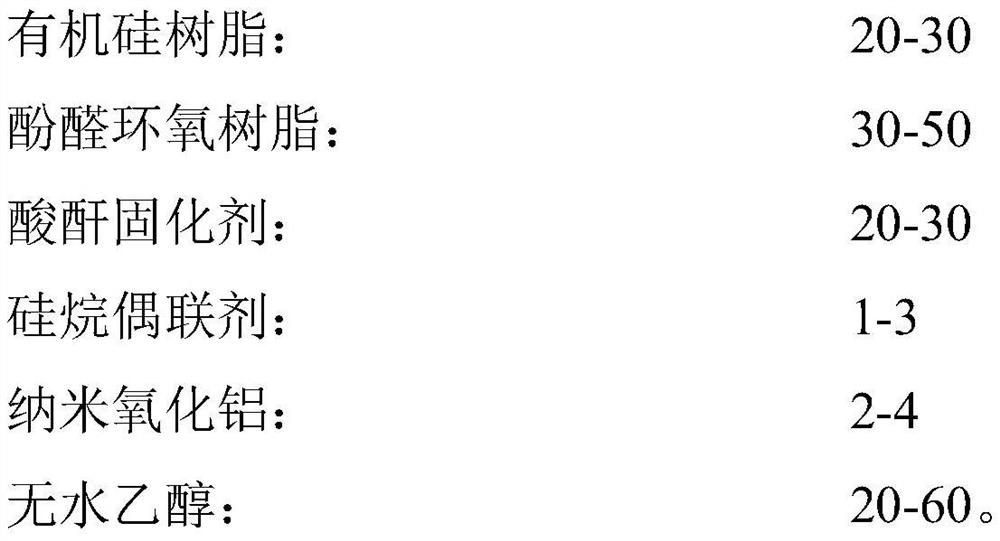

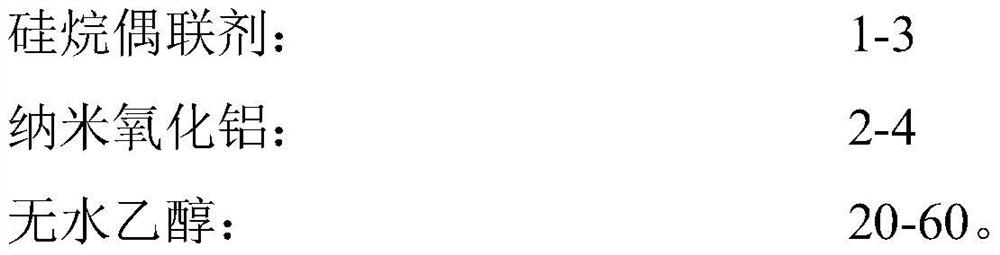

[0032] S1. At room temperature, 3g of nano-alumina is uniformly dispersed in 37g of absolute ethanol solution and ultrasonically oscillated, and 40g of o-cresol type novolac epoxy resin is added, stirred and mixed to obtain novolak epoxy resin-nano-alumina solution;

[0033] S2. Add 20 g of hydroxyl-terminated polydimethylsiloxane to the novolak epoxy resin-nano-alumina solution, mix and add 1 mass part of γ-aminopropyltriethoxysilane and stir evenly, then add 28g of methyl hexahydrophthalic anhydride curing agent was mixed and stirred evenly to prepare sample 1 of high-performance coating for metal film resistors.

Embodiment 2

[0035] S1. At room temperature, 4g of nano-alumina is uniformly dispersed in 60g of absolute ethanol solution and ultrasonically oscillated, and 50g of o-cresol type novolac epoxy resin is added, stirred and mixed to obtain novolak epoxy resin-nano-alumina solution;

[0036] S2. Add 30 g of hydroxyl-terminated polydimethylsiloxane to the novolak epoxy resin-nano-alumina solution, mix and add 3 parts by mass of γ-aminopropyltriethoxysilane and stir evenly, then add 30g of methyltetrahydrophthalic anhydride curing agent was mixed and stirred uniformly to prepare high-performance coating sample 2 for metal film resistors.

Embodiment 3

[0038] S1. Disperse 2g of nano-alumina evenly in 35g of absolute ethanol solution at room temperature and use ultrasonic vibration, add 30g of bisphenol A novolac epoxy resin, stir and mix to obtain novolak epoxy resin-nano-alumina solution;

[0039] S2. Add 25g of hydroxyl-terminated polymethylphenylsiloxane to the novolak epoxy resin-nano-alumina solution, mix and add 1.5 parts by mass of γ-glycidyl etheroxypropyltrimethoxysilane and stir evenly , and then add 25g of methyl hexahydrophthalic anhydride curing agent and mix and stir evenly to prepare high-performance coating sample 3 for metal film resistors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com