Antibacterial paint surface protective film

A technology for protective film and paint surface, applied in the direction of biocide-containing paint, film/flake adhesive, coating, etc., can solve the problem of small molecule penetration, achieve excellent tensile properties, excellent self-healing properties , Reflective brightening effect improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

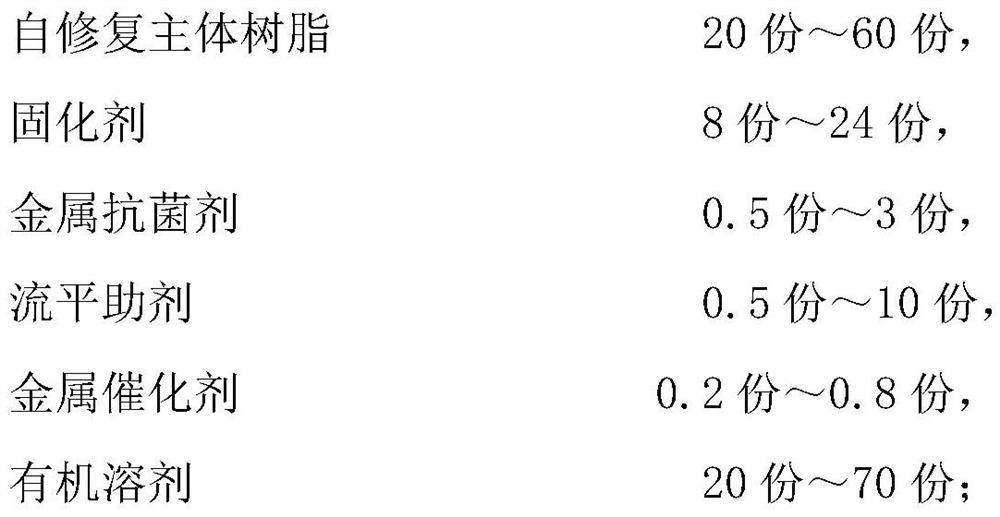

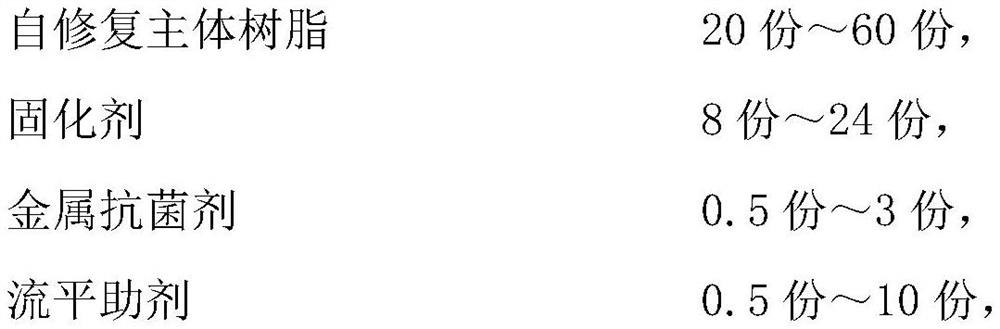

[0033] (1) Preparation of self-repairing type antibacterial protective layer coating solution:

[0034]

[0035] Add 42 parts by weight of high hydroxyl value self-healing main resin [JZ-9540-10, hydroxyl value 130mgKOH / g, Jiazhi Xinnuo Chemical], 2.4 parts by weight of metal silver ion antibacterial agent [particle size distribution 5-7nm , Shanghai Jing'an Industrial Co., Ltd. high-concentration nano-silver solution], 0.6 parts by weight of metal zinc ion antibacterial agent [particle size distribution 3-5nm, Shanghai Jing'an Industrial Co., Ltd. high-concentration nano-zinc solution], stirred for 30 minutes, and waited After the metal antibacterial agent is uniformly dispersed in the resin, add 12 parts by weight of butyl acetate solvent, 3.8 parts by weight of leveling aid [BYK-431, BYK Chemicals] and 0.2 parts by weight of catalyst [organotin catalyst DY-12, Deyin Chemical], stirred at high speed for 30 minutes, and then slowly added 18 parts by weight of low hydroxyl ...

Embodiment 2

[0039] (1) Preparation of self-repairing type antibacterial protective layer coating solution:

[0040]

[0041] Add 36 parts by weight of high hydroxyl value self-healing main resin [PU-361, hydroxyl value 120mgKOH / g, Zhongshan Jieshida Fine Chemical Co., Ltd.], 1.4 parts by weight of metal silver ion antibacterial agent [Langyixin material, AntibacMax], 0.6 parts by weight of metal zinc ion antibacterial agent [Langyi new material, AntibacMax], stirred for 30 minutes, after the metal antibacterial agent was uniformly dispersed in the resin, added 29.6 parts by weight of ethyl acetate solvent, 10 parts by weight 10 parts of leveling aid [BYK-3570, BYK Chemicals] and 0.4 parts by weight of catalyst [T-12, American Air Chemicals], stirred at high speed for 30 minutes, mixed well and then slowly added and diluted with 10 parts by weight of butyl acetate 4 parts by weight of low hydroxyl value resin [YP31-7EXS, hydroxyl value 70mgKOH / g, Shanghai Yuanbang Chemical Manufacturing...

Embodiment 3

[0045] (1) Preparation of self-repairing type antibacterial protective layer coating solution:

[0046]

[0047] Add 28.8 parts by weight of high hydroxyl value self-healing main resin [DIANAL LR-7568, hydroxyl value 140mgKOH / g, Mitsubishi Rayon Polymer Materials Co., Ltd.], 0.4 parts by weight of metal silver ion antibacterial agent [zeomic silver ion Antibacterial agent, Japan Zeomic], 0.1 parts by weight of metal zinc ion antibacterial agent [zeomic zinc ion antibacterial agent, Japan Jieomic], stirred for 30 minutes, after the metal antibacterial agent was dispersed evenly in the resin, add 20.5 parts by weight propylene glycol methyl ether solvent, 4.4 parts by weight of leveling aid [BYK-335, BYK Chemicals] and 0.6 parts by weight of catalyst [rare earth catalyst B-18, Casso additive], stirred at high speed for 30 minutes, and then mixed evenly Slowly add 7.2 parts by weight of low hydroxyl value resin [DIANAL LR-7506, hydroxyl value 66mgKOH / g, Mitsubishi Rayon Polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com