Double-electrode photoelectrochemical immunosensor, preparation method and application thereof

An immunosensor and photoelectrochemical technology, applied in scientific instruments, instruments, and material analysis through electromagnetic means, can solve the problems of low detection sensitivity and weak current signal, and achieve high sensitivity, low cost, and light detection of target antigen Ag. Significant effect of current signal response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Detection condition optimization

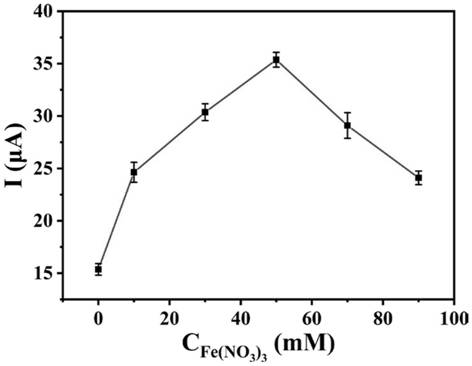

[0041] 1. Fe(NO 3 ) 3 concentration of solution

[0042] Due to Fe-TiO 2 / ZnIn 2 S 4 The photocurrent output of the photoanode has an important influence on the detection sensitivity of the final prepared dual-electrode photoelectrochemical immunosensor, so the following is for Fe-TiO 2 / ZnIn 2 S 4 The preparation process parameters of the photoanode were optimized:

[0043] Because Fe element is in TiO 2 The doping content in nanotubes can be controlled by Fe(NO 3 ) 3 The concentration of Fe(NO 3 ) 3 The concentration is optimized as follows:

[0044] Set the modified area to 0.25cm 2 The Ti foil was vertically inserted into 0.5% HF aqueous solution containing 0mM, 10mM, 30mM, 50mM, 70mM, 90mM Fe(NO 3 ) 3 , using the anodic oxidation method, applying a constant voltage of 10V for 20min, followed by calcination at 450°C in an air atmosphere for 1h, and naturally cooling to room temperature to obtain Fe-TiO 2 Nanotube p...

Embodiment 2

[0065] Fe-TiO 2 Fabrication of nanotube photoanode substrates

[0066] Set the modified area to 0.25cm 2 The Ti foil was vertically inserted into a 0.5% HF aqueous solution containing 50mM Fe(NO 3 ) 3 , using the anodic oxidation method, applying a constant voltage of 10V for 20min, followed by calcination at 450°C in an air atmosphere for 1h, and naturally cooling to room temperature to obtain Fe-TiO 2 Nanotube photoanode substrate.

[0067] Scanning electron microscopy results are attached Figure 6 As can be seen from the figure, Fe-TiO 2 The nanotube photoanode substrate is an array structure composed of a large number of highly ordered nanotubes, with an average diameter of about 50nm and a wall thickness of about 10nm; this structure has a large specific surface area, which is conducive to the subsequent large amount of ZnIn 2 S 4 The deposition of nanocrystals; moreover, the element distribution map in the inset illustrates the TiO 2 Successful doping of Fe elem...

Embodiment 3

[0069] Fe-TiO 2 / ZnIn 2 S 4 Preparation of photoanode

[0070]Fe-TiO prepared by embodiment 2 2 Nanotube photoanode substrates were sequentially immersed in 0.1M Zn(NO 3 ) 2 Methanol solution, 0.1M Na 2 S Methanol / water mixed solution (v / v=1:1), 0.1M InCl 3 Methanol solution, 0.1M Na 2 S methanol / water mixed solution (v / v=1:1) for 2 min each, washed with methanol solution in each step, repeated 3 times, calcined in 180°C air atmosphere for 1 h, and cooled naturally to room temperature.

[0071] Among them, the results of the scanning electron microscope are attached as Figure 7 As shown, it can be seen from the figure that ZnIn 2 S 4 Nanocrystalline particle size is about 10-15nm, uniformly distributed in Fe-TiO 2 The exterior and interior of the nanotube wall. And the Fe-TiO 2 / ZnIn 2 S 4 X-ray diffraction of the photoanode Figure 8 As shown, the results show that ZnIn 2 S 4 The characteristic diffraction peaks at 2θ = 27.8, 30.5° and 47.3° correspond to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com