Preparation method of lithium-sulfur battery cathode material

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, secondary battery manufacturing, etc., can solve the problems of unsuitable for large-scale production, low conductivity of carbon materials, unsuitable for conventional use, etc., to improve charging The effect of discharge performance, large specific surface area, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

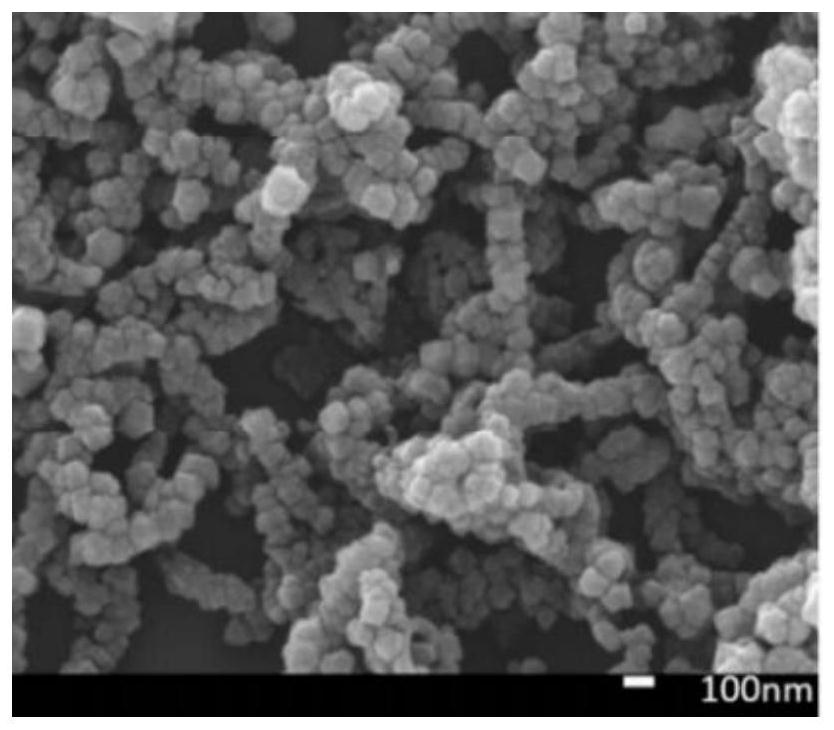

Image

Examples

Embodiment 1

[0027] A kind of cathode material of lithium-sulfur battery, its preparation method comprises the following steps:

[0028] S1: Add 1g of carbon nanotube CNT into 75ml of concentrated nitric acid, stir in a water bath at 80°C for 4h, then wash with ultrapure water and dry, grind the dried CNT into powder, and wash with absolute ethanol for 3 times , vacuum drying;

[0029] S2: Add 0.5g of the product of step S1 into a mixed solution of 25ml of methanol and 50ml of water, add 0.5g of melamine and stir until completely dissolved, then stir at 80°C until the solution is completely volatilized, then transfer the mixture to a tube furnace, and Nitrogen, calcined at 900°C for 1.5h, finally washed with ultrapure water and ethanol and dried;

[0030] S3: Mix 0.5g of the product of step S2 and 1.25g of sulfur powder into a mortar, grind for 30min, then transfer it to a vacuum glass tube, calcinate at 150°C for 20h, then heat up to 220°C for 3h;

Embodiment 2

[0041] A kind of cathode material of lithium-sulfur battery, its preparation method comprises the following steps:

[0042] S1: Add 1g of carbon nanotube CNT to 50ml of concentrated nitric acid, stir in a water bath at 100°C for 3 hours, then wash with ultrapure water and dry, grind the dried CNT into powder, and wash with absolute ethanol for 3 times , vacuum drying;

[0043]S2: Add 0.5g of the product of step S1 into a mixed solution of 30ml of methanol and 60ml of water, add 0.5g of melamine and stir until it is completely dissolved, then stir at 80°C until the solution is completely volatilized, then transfer the mixture to a tube furnace and pass it into Nitrogen, calcined at 800°C for 2h, finally washed with ultrapure water and ethanol and dried;

[0044] S3: Mix 0.5g of the product of step S2 and 1g of sulfur powder into a mortar, grind for 30min, then transfer it to a vacuum glass tube, calcinate at 150°C for 16h, then heat up to 220°C for 4h;

[0045] S4: Add 0.5g o...

Embodiment 3

[0048] A kind of cathode material of lithium-sulfur battery, its preparation method comprises the following steps:

[0049] S1: Add 1g of carbon nanotube CNT to 100ml of concentrated nitric acid, stir in a water bath at 60°C for 5h, then wash with ultrapure water and dry, grind the dried CNT into powder, and wash with absolute ethanol for 3 times , vacuum drying;

[0050] S2: Add 0.5g of the product of step S1 into a mixed solution of 20ml of methanol and 40ml of water, add 0.5g of melamine and stir until it is completely dissolved, then stir at 80°C until the solution is completely volatilized, then transfer the mixture to a tube furnace and pass it into Nitrogen, calcined at 1000°C for 1h, finally washed with ultrapure water and ethanol and dried;

[0051] S3: Mix 0.5g of the product of step S2 and 1.5g of sulfur powder into a mortar, grind for 30min, then transfer it to a vacuum glass tube, calcinate at 150°C for 24h, then heat up to 220°C for 2h;

[0052] S4: Add 0.5g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

| Average discharge capacity | aaaaa | aaaaa |

| Average discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com