A method of processing chalcogenide glass

A technology of chalcogenide glass and particle size, which is applied in the field of infrared optics, can solve problems such as product surface scratches, achieve the effect of improving surface accuracy and stability, simple steps, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

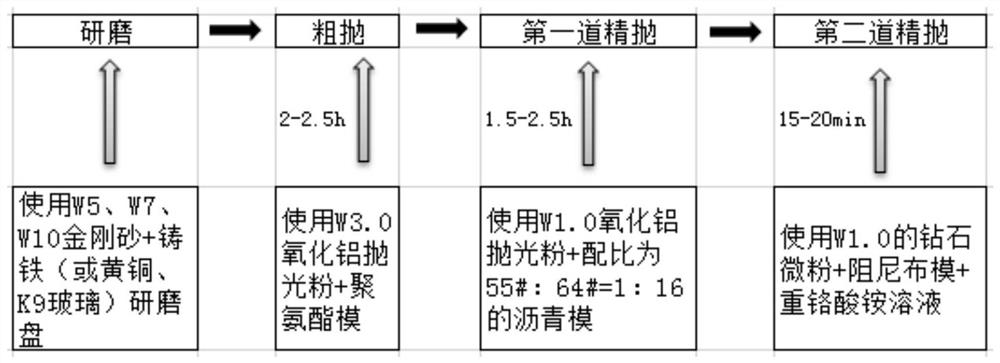

[0033] This embodiment provides a method for processing chalcogenide glass. The method for processing chalcogenide glass in this embodiment includes the following steps:

[0034] (1) The chalcogenide glass (specification: D40mm*2.4mm spherical surface; composed of As40Se60) is ground with a brass grinding disc and emery with a particle size of W10 to remove knife marks, chipping and other defects, while ensuring the thickness of the chalcogenide glass meet the requirements of the grinding step;

[0035] (2) rough polishing the chalcogenide glass obtained in step (1) with a polyurethane mold and alumina polishing powder with a particle size of W3.0, and the pressure is 2kgf / cm 2 , the spindle speed is 100RPM, the swing shaft speed is 60RPM, and the duration is 2h to remove trachoma;

[0036] (3) The chalcogenide glass obtained in step (2) is subjected to the first fine polishing using an asphalt mold and alumina polishing powder with a particle size of W1.0, wherein the aspha...

Embodiment 2

[0040] This embodiment provides a method for processing chalcogenide glass. The method for processing chalcogenide glass in this embodiment includes the following steps:

[0041] (1) The chalcogenide glass (specification: D103mm*14.85mm spherical surface; composed of As40Se60) is ground with a cast iron grinding disc and emery with a grain size of W10 to remove defects such as knife marks and chipping, and at the same time ensure that the thickness of the chalcogenide glass reaches Requirements for the grinding step;

[0042] (2) rough polishing the chalcogenide glass obtained in step (1) with a polyurethane mold and alumina polishing powder with a particle size of W3.0, and the pressure is 2kgf / cm 2 , the spindle speed is 100RPM, the swing shaft speed is 55RPM, and the duration is 2.5h to remove trachoma;

[0043] (3) The chalcogenide glass obtained in step (2) is subjected to the first fine polishing using an asphalt mold and alumina polishing powder with a particle size o...

Embodiment 3

[0047] This embodiment provides a method for processing chalcogenide glass. The method for processing chalcogenide glass in this embodiment includes the following steps:

[0048] (1) The chalcogenide glass (specification: D25.4mm*4mm wedge-shaped piece; composed of Ge10As40Se50) is ground with a cast iron grinding disc and emery with a particle size of W7 to remove defects such as knife marks and chipping, and at the same time ensure the chalcogenide glass. The thickness meets the requirements of the grinding step;

[0049] (2) rough polishing the chalcogenide glass obtained in step (1) with a polyurethane mold and alumina polishing powder with a particle size of W2.0, and the pressure is 1kgf / cm 2 , the spindle speed is 95RPM, the swing shaft speed is 55RPM, and the duration is 2h to remove trachoma;

[0050] (3) The first fine polishing of the chalcogenide glass obtained in step (2) is carried out using an asphalt mold and alumina polishing powder with a particle size of W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com