Method for preparing durene from carbon monoxide and methanol

A carbon monoxide and mesitylene technology, which is applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as restricting the production scale of mesitylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

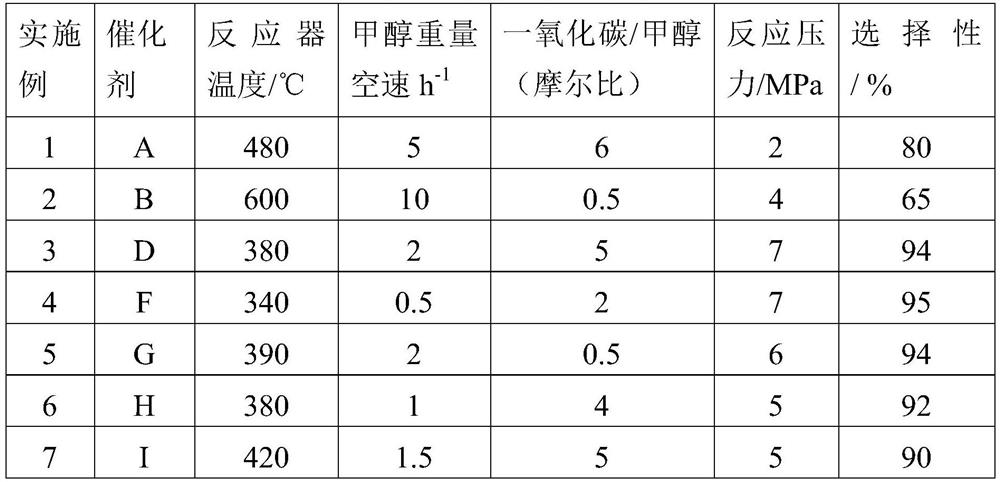

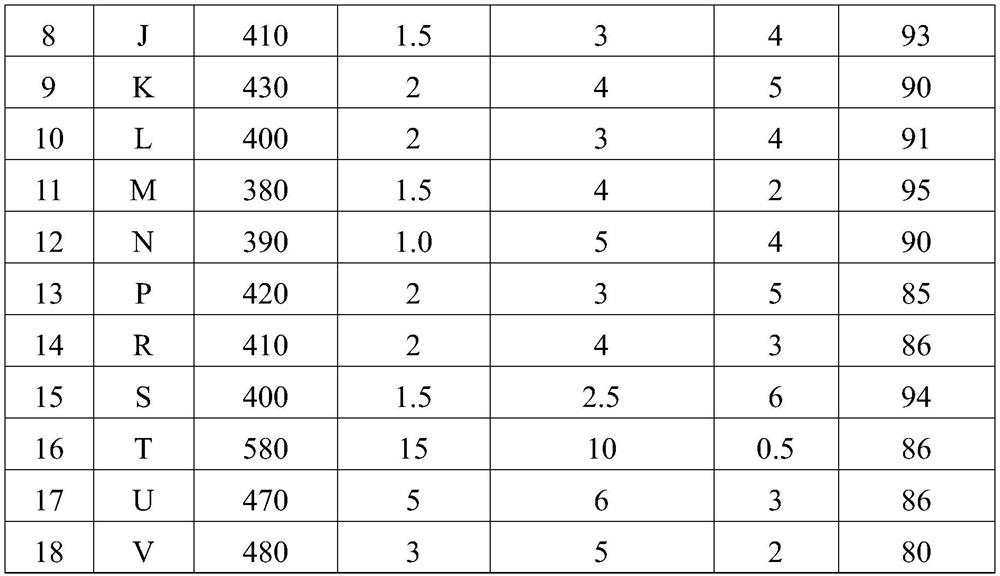

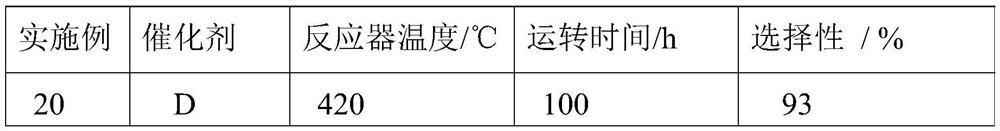

Examples

Embodiment 1

[0098] The preparation process of the catalyst is as follows: 120 grams of HZSM-5 molecular sieve with a molar silicon-aluminum ratio of 20 is mixed with 60 grams of diatomaceous earth and 100 grams of silicon dioxide with a weight content of 20% silica sol, and an appropriate amount of 10% dilute nitric acid is added as an auxiliary agent Extrusion molding. Dry at 120°C and bake at 500°C for 10 hours. The above-mentioned catalyst was cut into 1 mm to prepare columnar catalyst precursor A0 (ie intermediate product I).

[0099] The A0 sample of 20 grams was immersed in an aqueous solution containing copper nitrate and zinc nitrate for 12 hours, dried at 120°C, and roasted at 600°C for 3 hours. The weight content of copper oxide was 3%, and the weight content of zinc oxide was 3%. A1( That is the intermediate product II).

[0100] 20 grams of A1 was subjected to steam treatment in a 100% steam atmosphere for 10 hours at a temperature of 350° C., a pressure of 1.0 MPa, and roas...

Embodiment 2

[0103] The preparation process of the catalyst is as follows: 60 grams of HZSM-5 molecular sieve with a molar silicon-aluminum ratio of 30, mixed with 100 g of silica sol with a weight content of 40% by weight, and 100 grams of alumina, adding an appropriate amount of 10% dilute nitric acid as an auxiliary agent to extrude forming. Dry at 120°C and bake at 700°C for 4 hours. The above catalyst was cut into 3 mm to prepare columnar catalyst precursor B0.

[0104] 20 grams of B0 samples were immersed in an aqueous solution containing ferric nitrate and zinc nitrate for 12 hours, dried at 120°C, and roasted at 550°C for 10 hours. The weight content of iron oxide was 15%, and the weight content of zinc oxide was 1%. B1 was obtained.

[0105] 20 grams of B1 were subjected to steam treatment in a 100% steam atmosphere for 0.5 hour, the treatment temperature was 800° C., the pressure was 2.0 MPa, and the B2 was obtained by roasting at 600° C. for 3 hours.

[0106] Add 50ml of 1% by...

Embodiment 3

[0108] The preparation process of the catalyst is as follows: 200 grams of HZSM-5 molecular sieve with a molar silicon-aluminum ratio of 40 is mixed with 20 grams of diatomite and 30 grams of kaolin, and an appropriate amount of 10% dilute nitric acid is added as an auxiliary agent to extrude. Dry at 120°C and bake at 550°C for 4 hours. The above catalyst was cut into 1.5 mm to prepare columnar catalyst precursor D0.

[0109] 20 grams of D0 samples were immersed in an aqueous solution containing both zinc nitrate and cerium nitrate for 24 hours, dried at 120°C, and roasted at 600°C for 3 hours. The weight percentage of zinc oxide was 8%, and the weight percentage of cerium oxide was 1%. D1 was obtained. .

[0110] 20 grams of D1 were subjected to steam treatment for 10 hours in a 100% steam atmosphere, the treatment temperature was 350° C., the pressure was 3.0 MPa, and roasted at 650° C. for 3 hours to obtain D2.

[0111] Add 20 grams of D2 to 50 ml of 5% nitric acid soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com