High-alkali-stability anion exchange membrane and preparation method thereof

A carbon number and polymer technology, applied in the field of anion exchange membrane and its preparation, can solve the problems of severe hydrolysis, complex synthesis method, poor mechanical properties, etc., achieve uniform and dense membrane material, simple synthesis process, and improve alkali stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

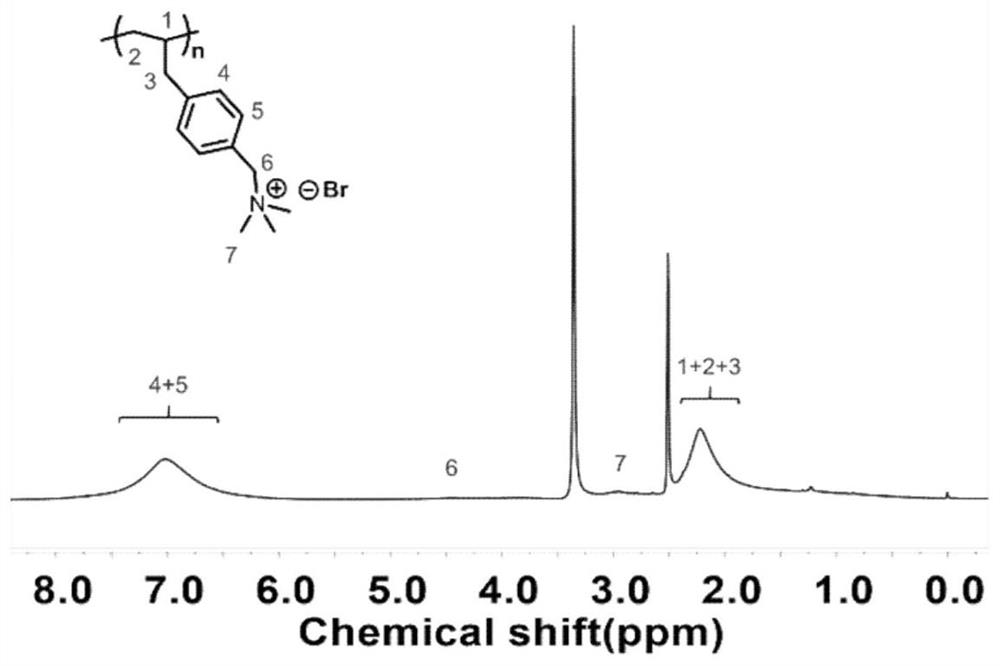

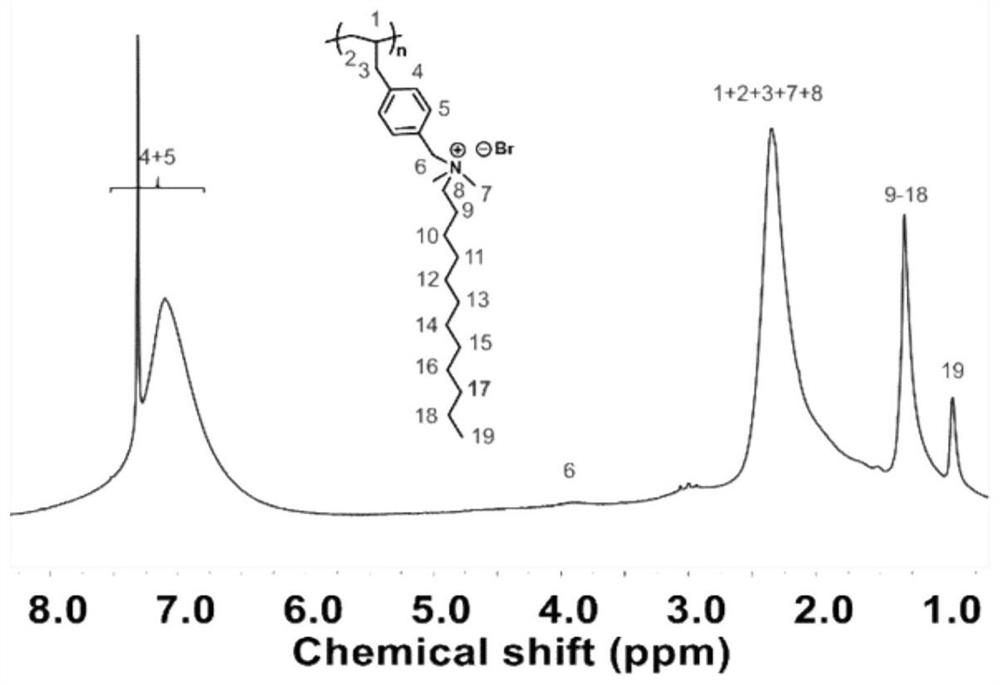

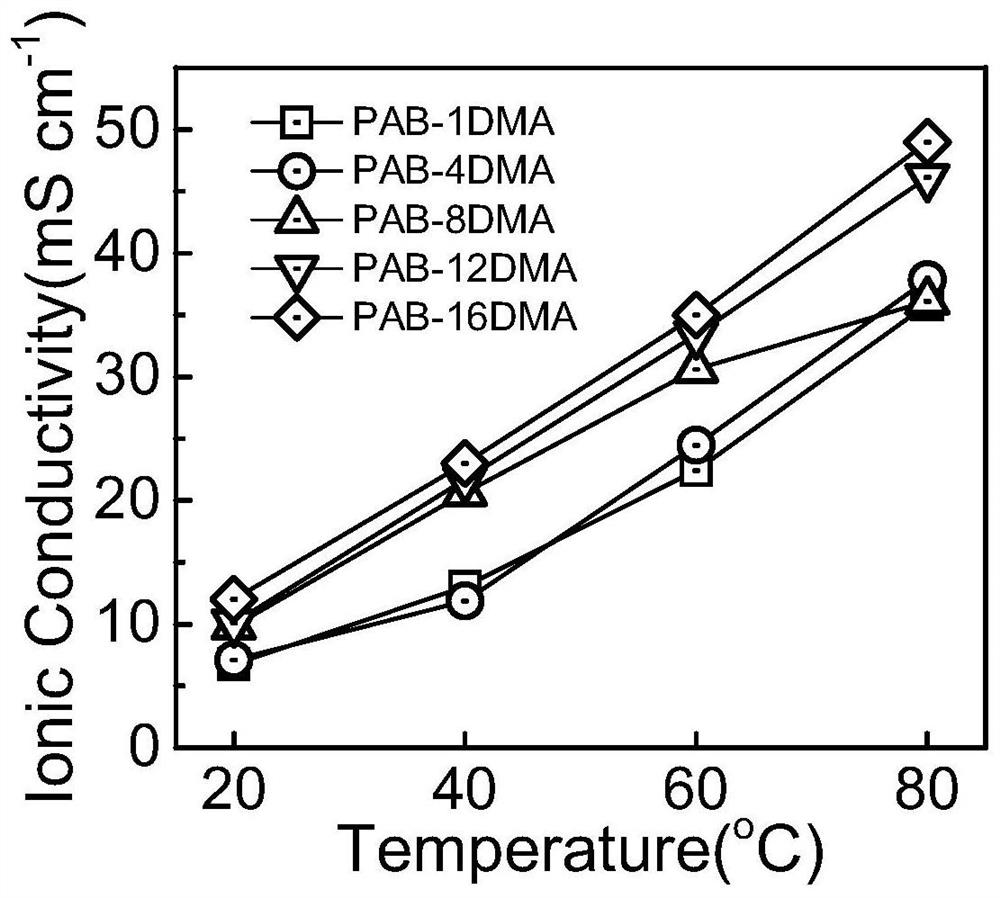

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 polymerization monomer (VTK):

[0035] Aluminum chloride (9.130 g, 68.47 mmol), dichloromethane (70.0 mL) and toluene (5.096 g, 55.307 mmol) were added to a 250 mL three-necked flask equipped with a magnetic stirrer. Acryloyl chloride (4.767 g, 52.668 mmol) diluted with 10.0 mL of dichloromethane was added from a constant pressure dropping funnel. Ice bath, react for 2 hours, and then transfer to 10% hydrochloric acid solution. The organic phase was repeatedly extracted with dichloromethane, washed with deionized water until neutral, and washed with anhydrous MgSO 4 dry.

Embodiment 2

[0036] Embodiment 2 polyvinyl ketone polymer (PVTK 100 ) preparation:

[0037]

[0038] Dissolve the dry and pure polymerization monomer in toluene, add the initiator azobisisobutyronitrile (AIBN), react at 60-70°C for 2 hours, pour the product into the methanol solution, and wash it with methanol to obtain the target polymerization thing.

Embodiment 3

[0039] Embodiment 3 polyvinyl ketone polymer (PVTK 200 ) preparation:

[0040]

[0041] Dissolve the dry and pure polymerized monomer in toluene, add the initiator azobisisobutyronitrile (AIBN), react at 60-70°C for 4 hours, pour the product into the methanol solution, and wash it with methanol to obtain the target polymer thing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com