A kind of superhydrophobic superwear-resistant anti-fog coating composition and its application

An anti-fog coating and super wear-resistant technology, applied in the field of coatings, can solve problems such as unstable wear resistance, poor water resistance of anti-fog coating, limited scratch resistance, etc., to improve hydrophobic performance, improve hydrophobicity, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

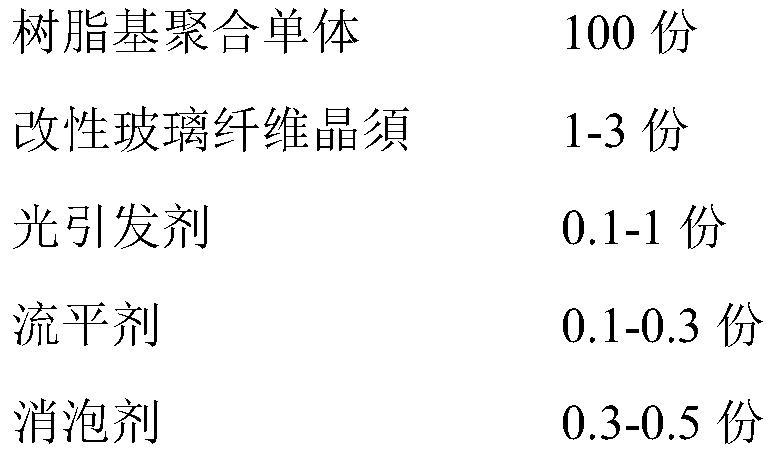

[0033] A super-hydrophobic super-abrasion-resistant anti-fog coating composition is formulated by weight from the following raw materials:

[0034] 100 parts of resin-based polymerized monomer, 3 parts of modified glass fiber whiskers, 2 parts of initiator composed of 1-hydroxycyclohexyl phenyl ketone and diaryliodonium salt at a mass ratio of 2:3, leveling agent BYK- 3330.2 parts, defoamer BYK0520.4 parts.

[0035] The resin-based polymerized monomer comprises the following components in parts by weight:

[0036] Silicone acrylate oligomer 70 parts

[0037] Silicon-containing acrylate monomer 30 parts.

[0038] The silicon-containing acrylate oligomer is prepared by the following method: the CN968 urethane acrylate of terminal hydroxypropyl polysiloxane and Sartomer Company is added to the reaction vessel at a molar ratio of -OH and -NCO of 0.8:1, while While stirring, raise the temperature to 50-60°C, add 0.3% of dibutyltin dilaurate and 0.01% of hydroquinone to the total...

Embodiment 2

[0045] A super-hydrophobic super-abrasion-resistant anti-fog coating composition is formulated by weight from the following raw materials:

[0046] 100 parts of resin-based polymerized monomer, 1 part of modified glass fiber whisker, 2-hydroxy-2-methyl-1-phenyl-1-propanone and diaryliodonium salt in a mass ratio of 3:1 1 part of agent, 0.1 part of leveling agent BYK-358N, 0.3 part of defoamer BYK17977.

[0047] The resin-based polymerized monomer comprises the following components in parts by weight:

[0048] Silicone acrylate oligomer 60 parts

[0049] Silicon-containing acrylate monomer 40 parts.

[0050] The silicon-containing acrylate oligomer is prepared by the following method: the CN981 urethane acrylate of terminal hydroxypropyl polysiloxane and Sartomer Company is added to the reaction vessel at a molar ratio of -OH and -NCO of 0.5:1, while While stirring, raise the temperature to 50-60°C, add 0.3% of dibutyltin dilaurate and 0.01% of hydroquinone to the total mass...

Embodiment 3

[0057] A super-hydrophobic super-abrasion-resistant anti-fog coating composition is formulated by weight from the following raw materials:

[0058] An initiator composed of 100 parts of resin-based polymerizable monomer, 3 parts of modified glass fiber whiskers, 2,4,6-trimethylbenzoyldiphenylphosphine oxide and triarylsulfonium salt in a mass ratio of 3:1 3 parts, leveling agent BYK-358N 0.3 parts, defoamer BYK1797 0.5 parts.

[0059] The resin-based polymerized monomer comprises the following components in parts by weight:

[0060] Silicone acrylate oligomer 70 parts

[0061] Silicon-containing acrylate monomer 30 parts.

[0062] The silicon-containing acrylate oligomer is prepared by the following method: the CN996 urethane acrylate of the terminal hydroxypropyl polysiloxane and Sartomer Company is added to the reaction vessel at a molar ratio of -OH and -NCO of 1:1, while While stirring, raise the temperature to 50-60°C, add 0.3% of dibutyltin dilaurate and 0.01% of hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com